APPLICATIONS

SMT Leading Manufacturer,Full Solution Expert.

Medical Electronics

Automotive Electronics

Aerospace & Defense

ETON TURNKEY SMT LINE

HOT

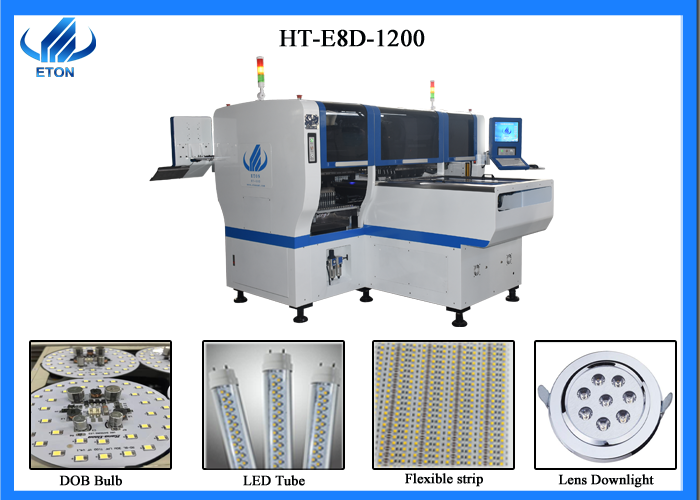

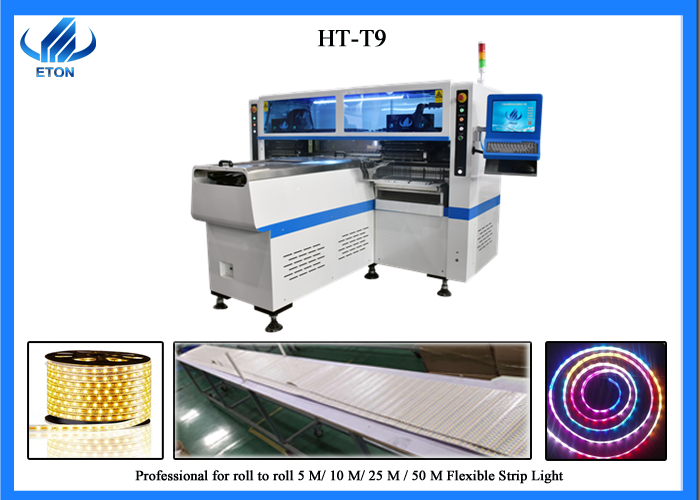

HT-T9

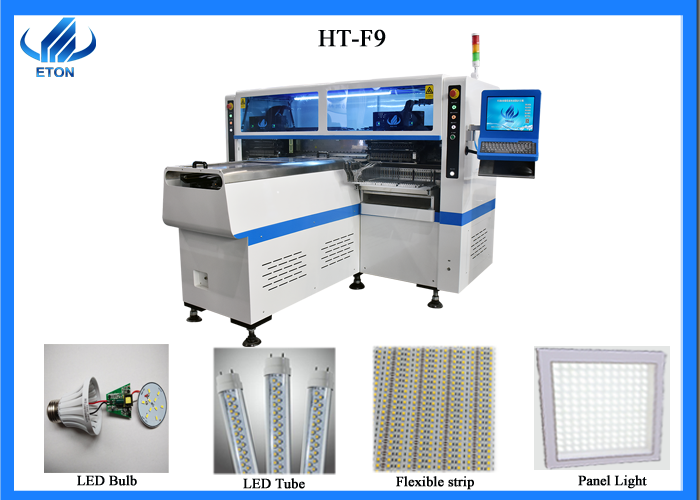

Led Strip Light HT-T9 200000CPH 68 Heads SMT Mounting Machine.

SMT Machines

SMT Conveyor, PCB loader machine, PCB unloader machine, SMT carrier…

High-Speed Dual Arm 200000 CPH SMT Mounting Machine 5pcs Camera, producing 4 types of materials at the same time.

PROJECTS

ETON machines are exported to more than 30 countries & regions

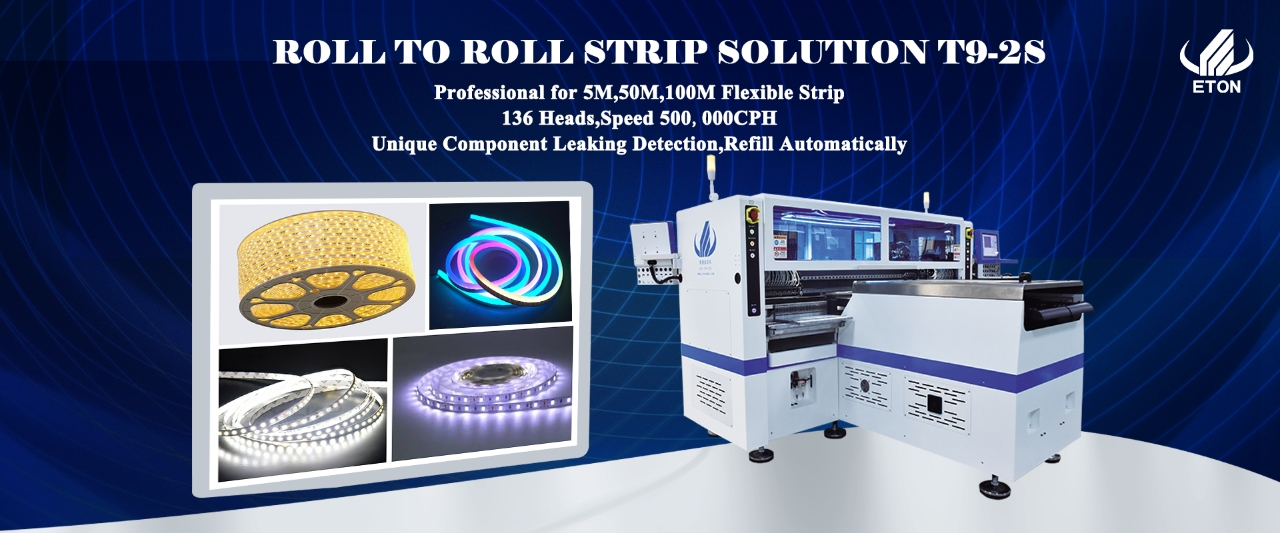

Client: India client

City: Delhi

Product:100M roll to roll Flexible strip

The client was in other business before, and then they planned to produce 100 meters of flexible light strips. The market prospect is very optimistic. ETON helped the client to plan the 100M production line, including the patch production line: PCB loader-semi-automatic printing machine-The buffer stage-high-speed pick and place machine – 24M assembly line – reflow oven – PCB unloader, and also planned 24M test line, sub-board line, coating production line. The client put into production in 2021, and the production situation is very good. ETON technicians installed the machine in the client’s factory, planned the wiring, tested the production, and trained the client’s engineers. The client’s project was very successful, becoming one of the few in India that can provide 100M without wires. The factory for the production of all flexible light strips is very competitive, and now is planning add a new SMT production line with ETON to expand production and LED product categories.

Client: Korean Client

City: Seoul

Product: LED bulb

Bought 4 multi-function placement machines, and made a fully automatic solution. The client is from Seoul, South Korea. They began to plan to produce LED bulb in 2016. Since the local labor cost is very expensive in South Korea, our company recommends the fully automatic production line solution. According to the client’s monthly production demand, we plan 4 fully automatic SMT production lines Scheme: PCB loader + Automatic stencil printer+Conveyor+ Pick and place machine + Conveyor. In order to save the client’s workshop and cost, we plan to use the robot arm to connect the PCB of 4 production lines, and placed the PCB on the same line automatically, which can not only separate the reflow soldering from the SMT workshop, but also save the cost of 3 reflow soldering machines. The client is very satisfied with this solution. After the client confirms the project and purchases the machine, the machine arrives at the factory. We plan the factory wiring for the client, and then arrange Chinese engineers to go to South Korea to install the machine for the client, provide training to the client’s engineers, and carry out Trial production and Mass Production until the production is smooth. Now the client’s machine has been working for 7 years, the machine is running very well, the client is very satisfied with ETON’s after-sales service and technical support, and the after-sales cost is also very low, the main parts of the machine are international brand with good quality and durable. ETON prove excellent quality, advanced technology, fast and timely after-sales service by time.

Client: Turkish client

City: Istanbul

Product: Led bulb/panel lights

The client used to do SKD, and plans to do SMT patch in 2021. The client need full automatic SMT production line with high capacity, but there are many components that to be mounted on the PCB board. After understanding these, ETON recommend purchasing two pick and place machines, one for LED chip and one for IC. , resistors, bridge rectifiers, etc., It’s can improve production capacity effectively. In October 2021, the client decided to purchase the full-automatic production line for the production of bulbs and panel lights and completed the installation at the end of 2021. Now the production is going very smoothly. In the process, client learned that ETON has been focusing on SMT pick and place machine for more than ten years, and has professional R&D team, factory, sales, and after-sales engineers, so they are very trusting and satisfied with ETON.In the new year, the client has launched a new plan, and the second ETON SMT production line is in the manufacturing stage and waiting to be shipped.Its mounted components mainly include LED chip , ic , bridge , socket , resistor, customer bulb size 12w, 18w, 24w and 30w, PCB board size: 12w: 240*240mm, 18w: 235*295mm, 24w: 267*267mm , 30w:269*269mm

Client: Egypt client

City: Cairo

Product: Led Bulb

The client first contacted ETON in September 2021, mainly producing LED bulbs, and planning to purchase the fully automatic SMT production line. After the sales understand the client’s production needs, due to the product requires high precision, the RT-1 pick and place machine is recommended.In constant communication, after the client understands ETON’s brand, scale and technology, client decides to purchase RT-1 full-automatic SMT production line from ETON: PCB loader-Conveyor-Automatic stencil printer-Conveyor-Pick and place machine-Conveyor-Reflow oven – PCB unloader. After the machine arrives at the client’s factory successfully, ETON arranges professional engineers to plan the wiring of the client’s factory, install the machine, and train the client’s engineers. Professional technology and worry-free service have won high praise from client. They are very satisfied with ETON’s products. They are in the recognition of ETON and introduce ETON to their friends.

ABOUT US

────

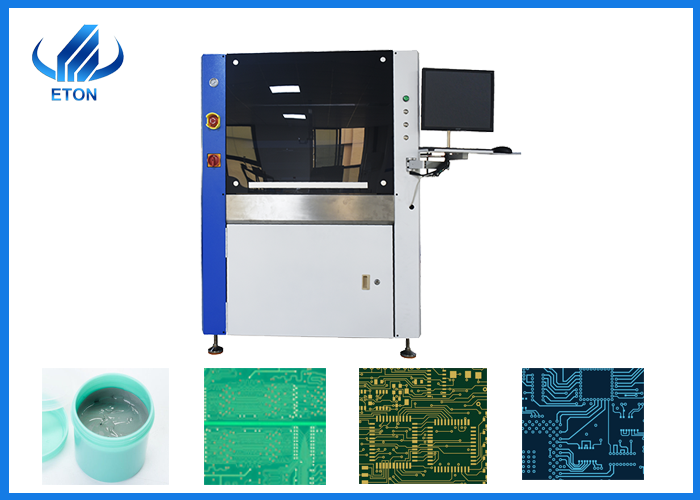

Shenzhen ETON Automation Equipment Co.,Ltd. is a leading manufacturing and process solution provider focusing on R&D, production,sales, and service of SMT high-speed pick and place machines and SMT peripheral automation equipment. ETON has SMT high-speed pick and places machine division, precision solder paste stencil printer division, high-speed precision dispensing equipment division, and SMT peripheral automation equipment, division. We support free installation on site and have local engineers in India, Turkey, Egypt. Ability to inform customers of production progress via video or photos.

52000㎡

FACTORY CENTER

1000+

PROJECT CASE

248+

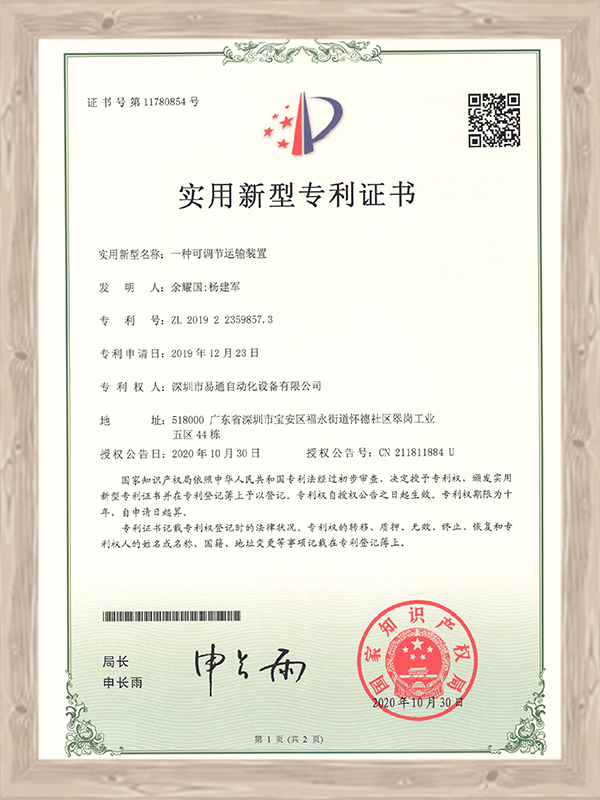

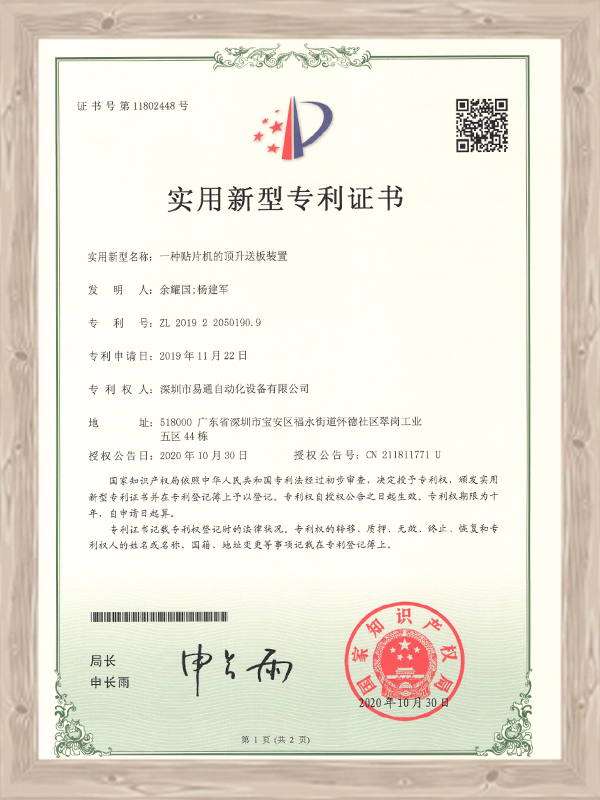

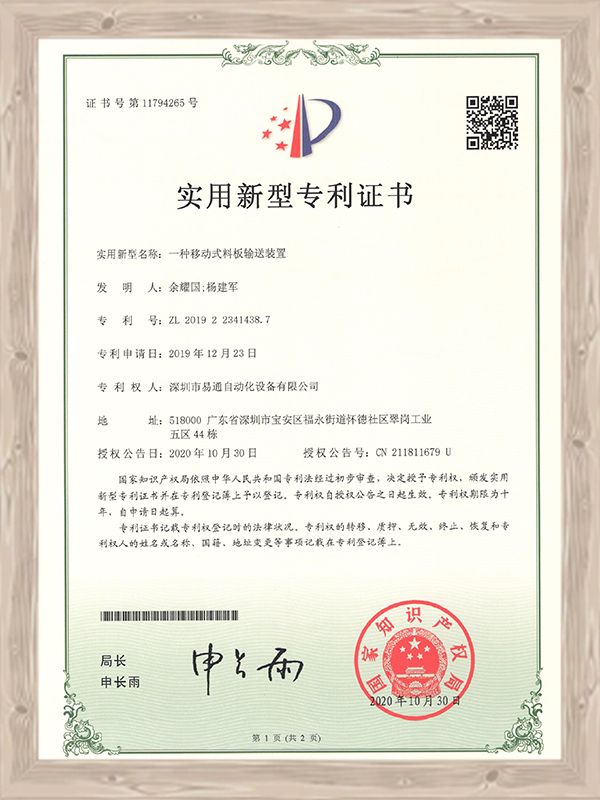

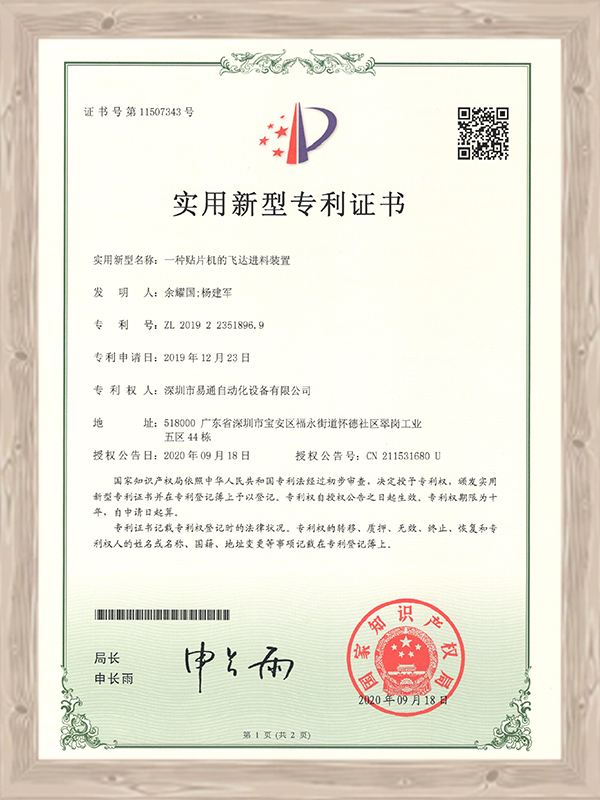

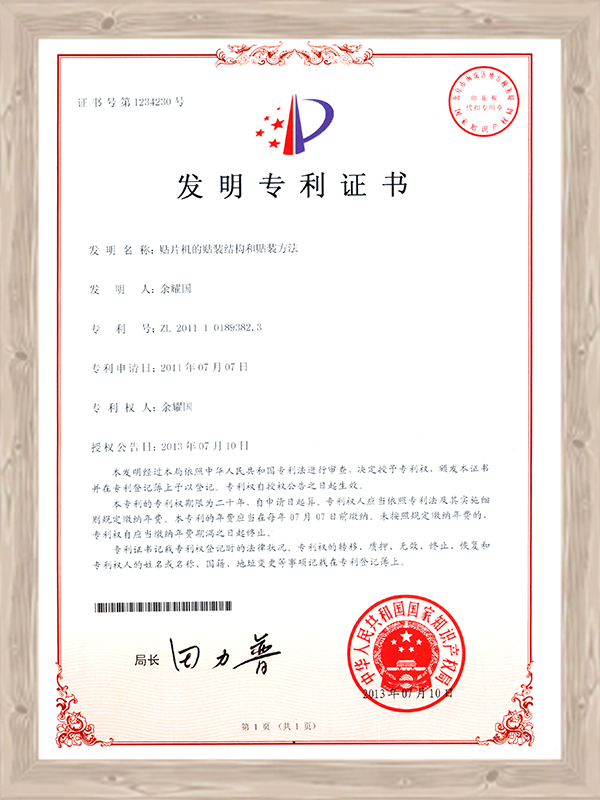

TECH PATENTS

30+

YEARS EXPERIENCE

VIDEO

ETON ET5235:Efficient and precision mounting expert

ETON HT-F9 Dual-Head SMT Machine

ETON ET-AL260 Fully automatic printing press Showcase

ETON YT20L SMT Mounter for led strip Production

HONOR

PARTNER

CUSTOMER VISIT

CONTACT US

SOLUTION

SMT Leading Manufacturer,Full Solution Expert.

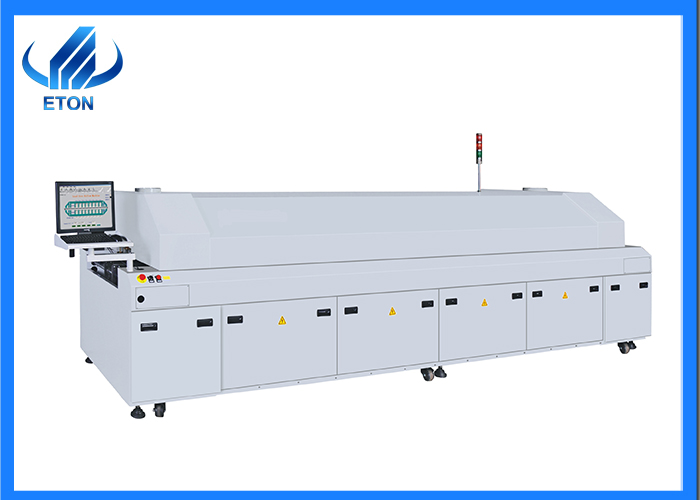

SMT Reflow Oven

SMT Machines

SMT Testing Machine

HOT

HT-T9

Led Strip Light HT-T9 200000CPH 68 Heads SMT Mounting Machine.

SMT Machines

SMT Conveyor, PCB loader machine, PCB unloader machine, SMT carrier...

High-Speed Dual Arm 200000 CPH SMT Mounting Machine 5pcs Camera, producing 4 types of materials at the same time.

PROJECTS

ETON machines are exported to more than 30 countries & regions

Client: India client

City: Delhi

Product:100M roll to roll Flexible strip

The client was in other business before, and then they planned to produce 100 meters of flexible light strips. The market prospect is very optimistic. ETON helped the client to plan the 100M production line, including the patch production line: PCB loader-semi-automatic printing machine-The buffer stage-high-speed pick and place machine - 24M assembly line - reflow oven - PCB unloader, and also planned 24M test line, sub-board line, coating production line. The client put into production in 2021, and the production situation is very good. ETON technicians installed the machine in the client's factory, planned the wiring, tested the production, and trained the client's engineers. The client's project was very successful, becoming one of the few in India that can provide 100M without wires. The factory for the production of all flexible light strips is very competitive, and now is planning add a new SMT production line with ETON to expand production and LED product categories.

Client: Korean Client

City: Seoul

Product: LED bulb

Bought 4 multi-function placement machines, and made a fully automatic solution. The client is from Seoul, South Korea. They began to plan to produce LED bulb in 2016. Since the local labor cost is very expensive in South Korea, our company recommends the fully automatic production line solution. According to the client's monthly production demand, we plan 4 fully automatic SMT production lines Scheme: PCB loader + Automatic stencil printer+Conveyor+ Pick and place machine + Conveyor. In order to save the client's workshop and cost, we plan to use the robot arm to connect the PCB of 4 production lines, and placed the PCB on the same line automatically, which can not only separate the reflow soldering from the SMT workshop, but also save the cost of 3 reflow soldering machines. The client is very satisfied with this solution. After the client confirms the project and purchases the machine, the machine arrives at the factory. We plan the factory wiring for the client, and then arrange Chinese engineers to go to South Korea to install the machine for the client, provide training to the client's engineers, and carry out Trial production and Mass Production until the production is smooth. Now the client's machine has been working for 7 years, the machine is running very well, the client is very satisfied with ETON's after-sales service and technical support, and the after-sales cost is also very low, the main parts of the machine are international brand with good quality and durable. ETON prove excellent quality, advanced technology, fast and timely after-sales service by time.

Client: Turkish client

City: Istanbul

Product: Led bulb/panel lights

The client used to do SKD, and plans to do SMT patch in 2021. The client need full automatic SMT production line with high capacity, but there are many components that to be mounted on the PCB board. After understanding these, ETON recommend purchasing two pick and place machines, one for LED chip and one for IC. , resistors, bridge rectifiers, etc., It’s can improve production capacity effectively. In October 2021, the client decided to purchase the full-automatic production line for the production of bulbs and panel lights and completed the installation at the end of 2021. Now the production is going very smoothly. In the process, client learned that ETON has been focusing on SMT pick and place machine for more than ten years, and has professional R&D team, factory, sales, and after-sales engineers, so they are very trusting and satisfied with ETON.In the new year, the client has launched a new plan, and the second ETON SMT production line is in the manufacturing stage and waiting to be shipped.Its mounted components mainly include LED chip , ic , bridge , socket , resistor, customer bulb size 12w, 18w, 24w and 30w, PCB board size: 12w: 240*240mm, 18w: 235*295mm, 24w: 267*267mm , 30w:269*269mm

Client: Egypt client

City: Cairo

Product: Led Bulb

The client first contacted ETON in September 2021, mainly producing LED bulbs, and planning to purchase the fully automatic SMT production line. After the sales understand the client's production needs, due to the product requires high precision, the RT-1 pick and place machine is recommended.In constant communication, after the client understands ETON's brand, scale and technology, client decides to purchase RT-1 full-automatic SMT production line from ETON: PCB loader-Conveyor-Automatic stencil printer-Conveyor-Pick and place machine-Conveyor-Reflow oven - PCB unloader. After the machine arrives at the client's factory successfully, ETON arranges professional engineers to plan the wiring of the client's factory, install the machine, and train the client's engineers. Professional technology and worry-free service have won high praise from client. They are very satisfied with ETON's products. They are in the recognition of ETON and introduce ETON to their friends.

ABOUT US

────

Shenzhen ETON Automation Equipment Co.,Ltd. is a leading manufacturing and process solution provider focusing on R&D, production,sales, and service of SMT high-speed pick and place machines and SMT peripheral automation equipment. ETON has SMT high-speed pick and places machine division, precision solder paste stencil printer division, high-speed precision dispensing equipment division, and SMT peripheral automation equipment, division.We support free installation on site and have local engineers in India, Turkey, Egypt. Ability to inform customers of production progress via video or photos.

20+

YEARS EXPERIENCE

52000㎡

FACTORY CENTER

132+

TECH PATENTS

8+

OVERSEAS OFFICE