- X,Y,and Z axis all adopt self-developed high-end magnetic linear motor

-

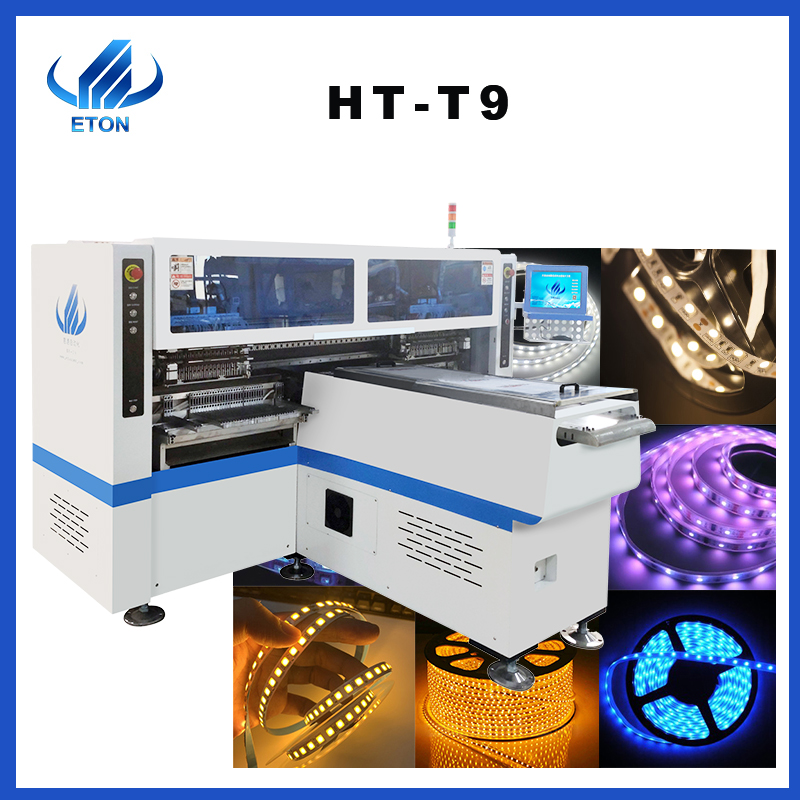

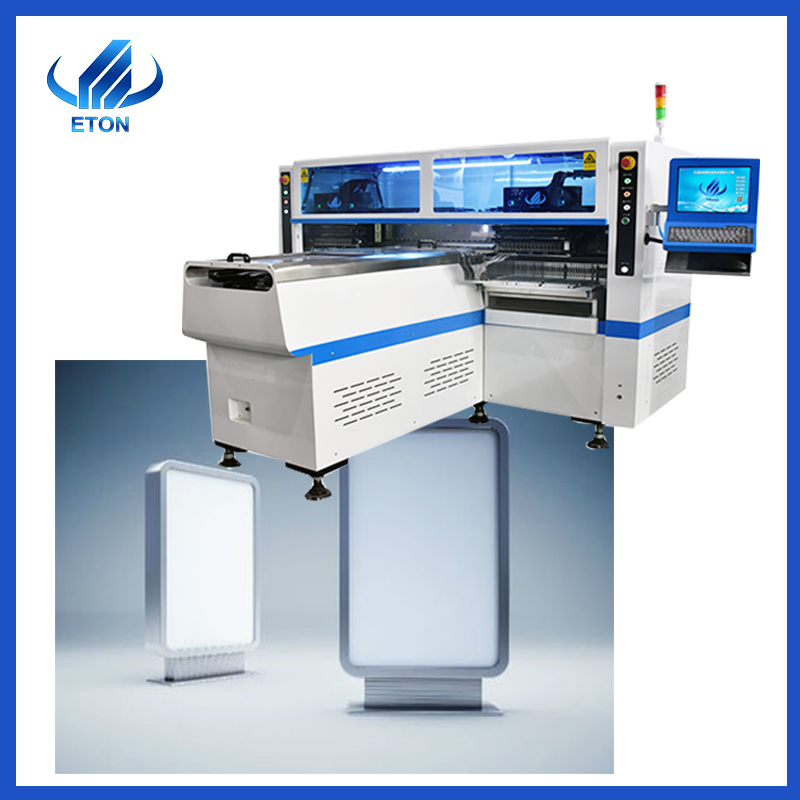

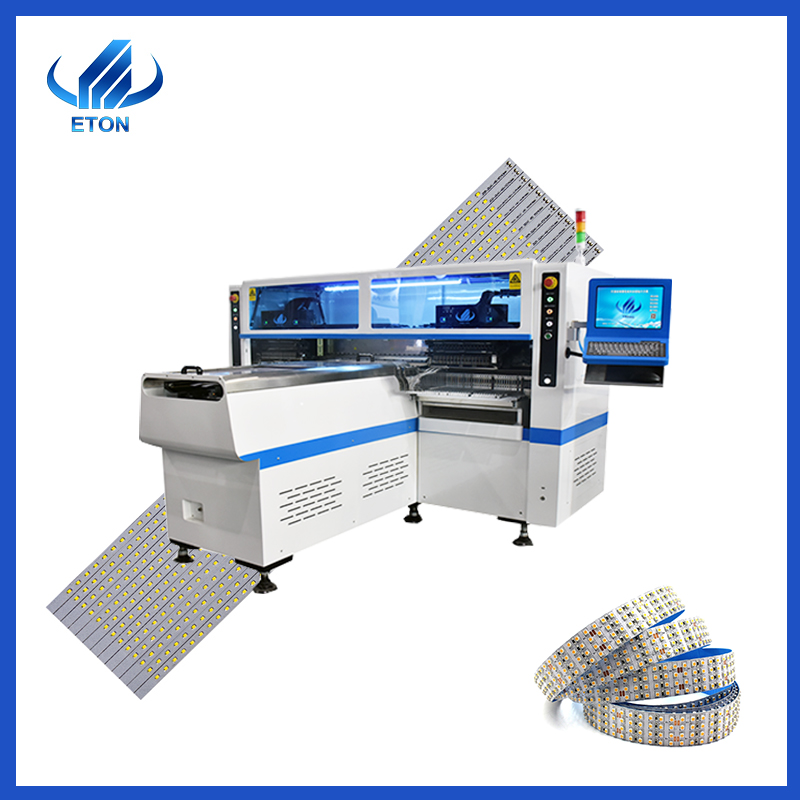

Flexible PCB handling capabilities, multi-station,multi-material mounting

-

Y axis adopts double drive gantry structure

-

Support automatic replacement nozzle function(option)

-

Apply to 0201~40*40mm tape reel package and IC tray feeder

1.5KW energy save 98000CPH SMT pick and place machine

Description

Machine main features

Integrated Placement Head

Lightweight, head is integrally formed, the 10 sets of Z axes are independently controlled by modular magnetic linear motor, which greatly improves the speed, accuracy and stability

Precision Corner System

The modular corner system independently controls the angle of each component to ensure high-precision placement. 10 suction nozzles per head, with a center distance of 16mm.

Vacuum Sensing Device

Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product.

Ultra-high-speed Capability

Adopting high-end magnetic linear motors and a multi-function Modular head, the placement capability has increased by 25% compared to traditional machines,with an optimum speed reaching 98000CPH

Machine main parameter

|

Model |

YT20S |

|

Dimension |

|

|

Length |

1480mm |

|

Width |

2680mm |

|

Height |

1650mm |

|

Total Weight |

2380kg |

|

PCB |

|

|

PCB Length Width |

Max:500*300mm(1200*450 option) Min:50*50mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Cylinder clamping, track width adjustable |

|

Mounting Mode |

Group picking and separate placing\separate picking and separate placing |

|

O.S. |

|

|

System |

Windows7 |

|

Software |

R&D independently |

|

Display |

LED monitor |

|

Input Device |

Keyboard, Mouse |

|

Vision System |

|

|

No. of Camera |

1 PCS (Head flight vision camera) |

|

2 PCS Mark camera |

|

|

Mounting Precision |

CHIP±0.03mm QFP±0.025mm Cpk ≧1.0 (3σ) |

|

Mounting Height |

≦16mm (Other height can be customized) |

|

Mounting Speed |

98000 CPH(Under best condition) |

|

Components |

0201~12MM packaging material and IC material(Optional fixed camera for 0201~35*35MM),Other component size can be customized |

|

Components Space |

0.2mm |

|

No. of Feeders Station |

104 PCS |

|

No. of nozzles |

20 PCS |

|

Power |

220AC 50HZ |

|

Power Consumption |

1.5kw |

|

Operating Environment |

23℃±3℃ |

|

Transmission Speed |

>1000mm/sec |

|

Transmission Direction |

Single(left→ right or right→ left) |

|

Transmission Mode |

Online drive |

|

Position Mode |

Optical |

|

Gas consumption |

0.4-0.6mpa (4-6kgf/cm2)600N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 1 set |

Independent research and development by ETON |

|

X,Y,Z Axis Drive way |

High-end magnetic linear motor |

|

Feeding way |

Intelligent feeder with double motor |

|

Production management MES system interface |

Customized |

Our Exhibitions

Our company has participated in various exhibitions in foreign countries, including India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, etc.

Our advantage

- Focusing on SMThigh speed pick and place machine more than 20 years

- The products exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc.

- ETON obtained 9 invention patents, 112 practical patents, 12 software copyrights of intellectual property technologies, to be a leading manufacturer of SMT trade.

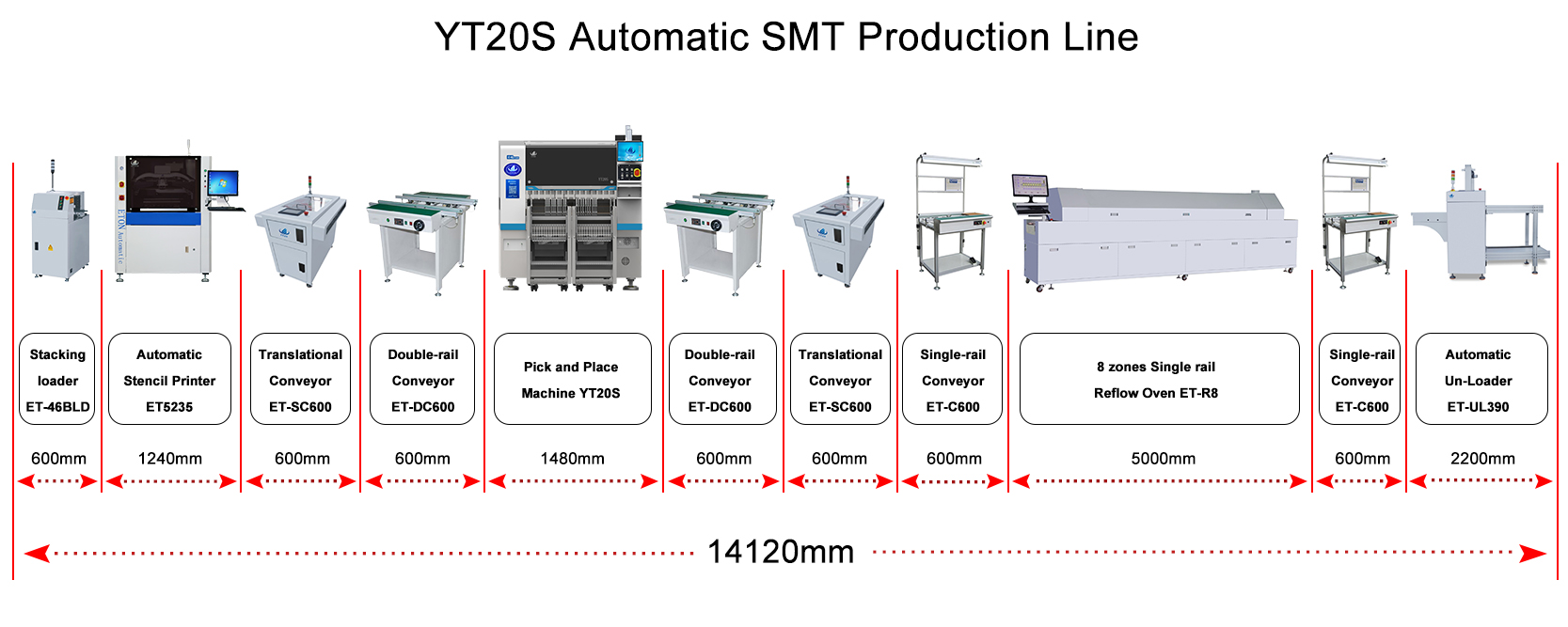

SMT Line solution

Shipping and Delivery

Shipping Way:

※ By air, for sample and small package

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 30 Days.

FAQ

Q: Do you have oversea after sale service?

A: We can provide technical support abroad. If you have any technical problems, our engineers will provide you with timely support.Abroad, we have India office, Indian engineer, Jerusalem office, engineer, Egyptian engineer, etc.

Q: How is the training?

A: After purchasing our machines, you can send your engineers to our factory, or we send our engineers to your factory, and then we will train your personnel to operate these machines. Online training and video tutorials.

Q: If I need a perfect line of the machine can you supply?

A: Yes, for the requirements of a whole line for production, we have professional equipment to make up for a perfect production line for your products, on account of we have a 50000 square meters of industrial park and excellent R&D staff, which can produce 50 sets of machine per month.

Q: How was your services?

A: We ensure our clients to enjoy an optimal experience of the service of communication and relevant needs of the machine for installation, maintenance and free up- grade

Contact me

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com