Description

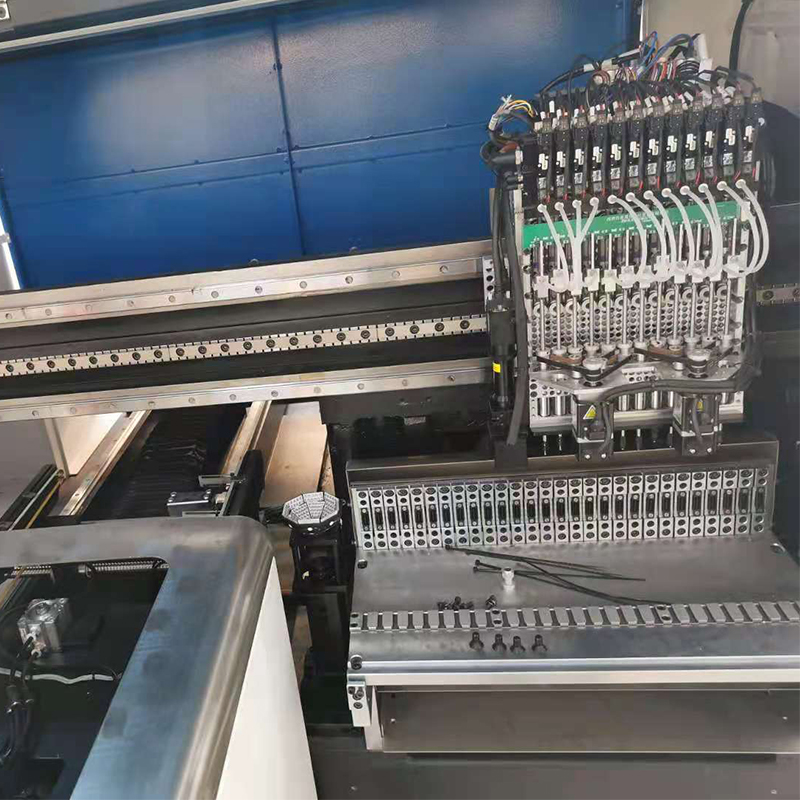

the machine features

Component: Min.size 0402 Max.height 15mm.

Mounting components: LED chip, capacitors, resistors, lens, IC, shaped components, etc.

Application: power driver, electric board, lens, DOB bulb, linear bulb, household appliance, etc.

Exclusive patented technology

Electronic feeder feeding system.

Vision alignment flight identification, Mark correction.

Non-stop material re-loading function.

Auto-optimization after coordinates generated, etc.

|

Model |

HT-E8S-1200 |

|

|

Dimension |

Length |

2550mm |

|

Width |

1650mm |

|

|

Height |

1550mm |

|

|

Total weight |

1700kg |

|

|

PCB |

PCB length width |

Max:1200*500mm Min:100*100mm |

|

PCB thickness |

0.5-5mm |

|

|

PCB clamping |

Adjustable pressure pneumatic |

|

|

Mounting mode |

Group picking and separately placing, separately picking and separately placing |

|

|

O.S. |

System |

Windows 7 |

|

Software |

R&D independently |

|

|

Input device |

Keyboard, mouse |

|

|

Vision system |

No.of camera |

2 sets of imported camera(vision for the flight identification, mark correction) |

|

Mounting precision |

±0.04mm |

|

|

Mounting height |

<15mm(automatic changing) |

|

|

Mounting speed |

45000CPH |

|

|

Components space |

0.2mm |

|

|

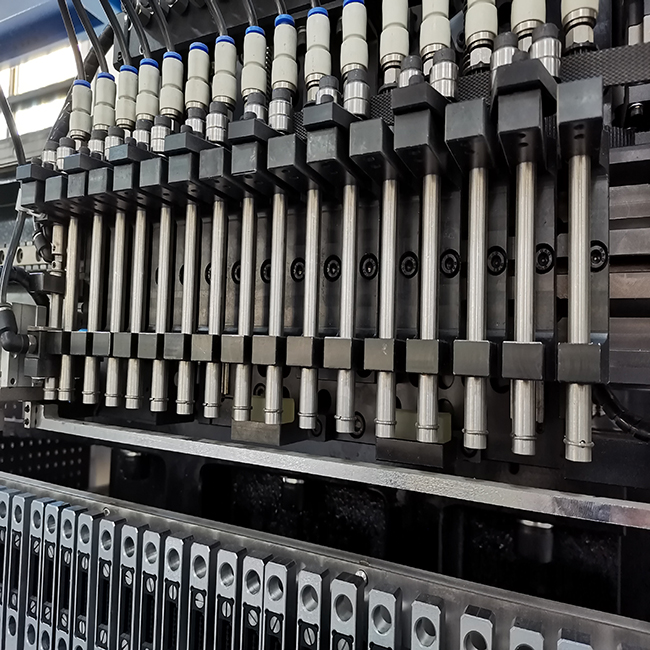

Air supply |

0.4-0.6mpa, 150N/min |

|

|

Electrical control |

Independent research and development by ETON |

|

|

X,Y,Z axis drive way |

High-end magnetic linear motor+servo motor |

|

|

Feeding system |

No.of feeders station |

28PCS single module |

|

No.of head |

12 PCS single module |

|

|

Feeding way |

Electric feeder with double motor |

|

Company introduction

Our company was founded in 2011, is a manufacturing and process solution provider focusing on R&D, production, sales, service of SMT high-speed pick and place machines and SMT peripheral automation equipment.

Exhibition

ETON is the leading manufacturer of global op to-electronic high-speed pick and place machine, the products are exported to more than 20 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt, Turkey, Russia, Brazil etc. We go to the exhibition every year. Our team is professional in the SMT field. And We go to the exhibition every year.

FAQ

1. Can you support whole SMT line?

Yes, we can provide whole line solution if you want. We are very professional on SMT field.

2. Is the machine easy to operate?

Machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

3. How many hours does the machine can operate per day?

Machine can work whole day. But for longer using life, we suggest you to have 1 hour or 2 hours off per day.

4. Do you have any customers in India? How many machines are there in India?

Yes, we have many big clients in India, such as RK,SURYA,Fiem,Calcom, POLYCRB,etc. We have sold over a hundred machines to India and we go to the exhibition every year.

5.Can I use CIF price?

CIF price need add the freight, insurance fee on the basis of EXW price, and the India delivery forwarder will charge ours more than yours. So actually to do EXW will more simple and save cost for you.

Maintenance period 1 year

- One year warranty, during warranty, any parts that need to be repaired and replaced will be free

Software and hardware lifetime maintenance

- Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates

Visit customers regularly and gather information

- Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time

Provide the latest information about technology and equipment

- We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

- We have some official site in India as Mumbai and New Delhi, also have site in Egypt. Turkey that can provide service timely with our engineers.

- According to your needs. dedicated senior engineer will come to your factory for free install and training you how to operate the machine.