Description

Machine parameter

|

Model |

YT-202 |

|

Dimension |

2317*1376*1762mm |

|

PCB size |

Max size: 500*450mm(single PCB) 500*300mm(double PCB) Min size: 50*50mm |

|

PCB thickness |

0.5-4.5mm |

|

PCB clamping |

Cylinder clamping, track width adjustable |

|

Off-line programming |

Available |

|

No. Of camera |

4 sets |

|

Repeat precision |

±0.02mm |

|

Mounting speed |

90000CPH |

|

Components range |

Min0201-10mm package and IC etc. |

|

No. Of feeder station |

Double side: 32PCS,total tape reel package 64 PCS (single side 16PCS, total tape reel package 32PCS) |

|

No. Of heads |

Double side: 20PCS (single side: 10PCS) |

|

Feeding way |

Intelligent double head feeder |

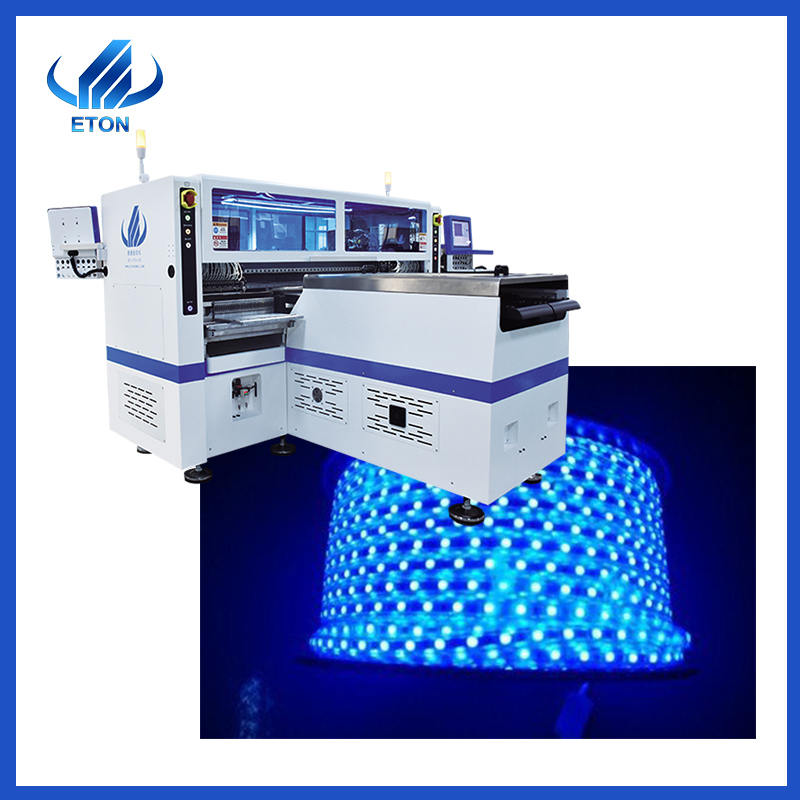

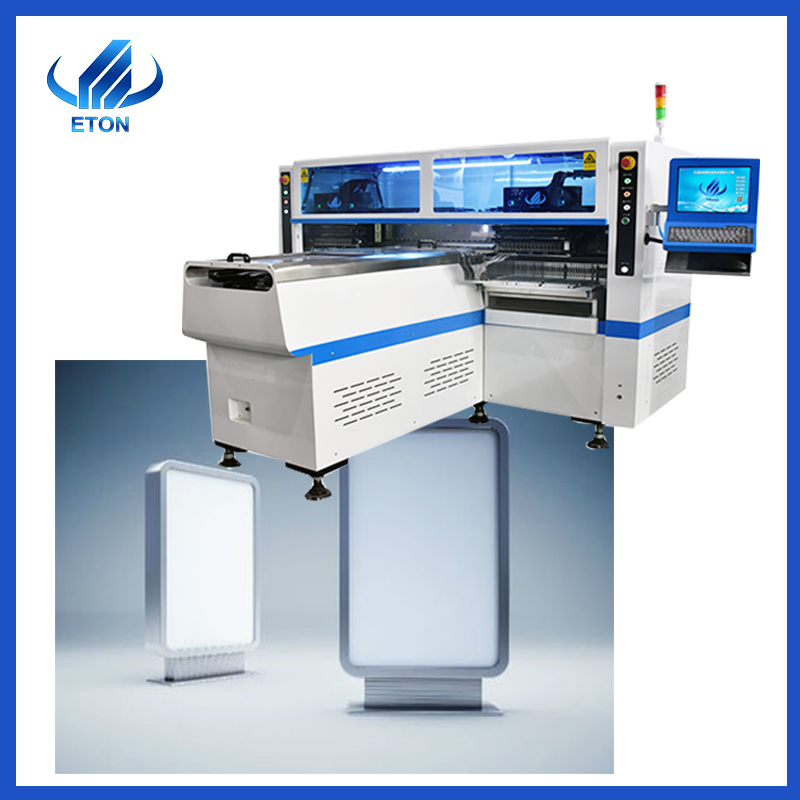

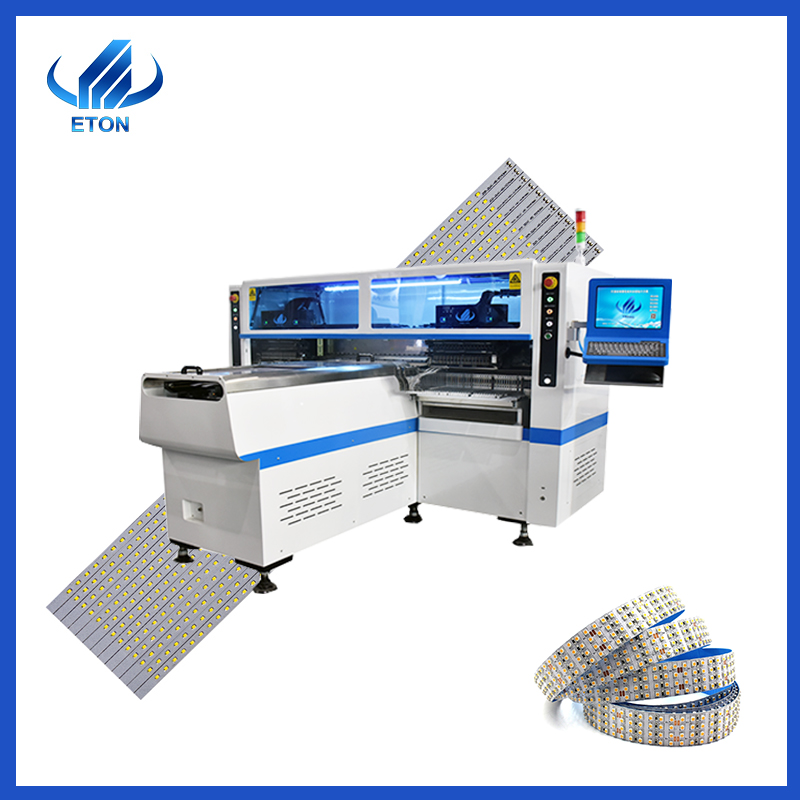

Feature

- Machine highlight: high-speed multi modular head; modular head; brand new flight vision camera; vacuum sensing device; ultra-high-speed capability

- Flexible production: head flight vision recognition camera; intelligent electric feeder

- High reliability

- Transmission system structure

- The optimal speed: 90000CPH

- Apply to 0201-10mm tape reel package and IC tray feeder

Company

Since its establishment in 2011, ETON has been committed to the development and production of SMT placement machines and peripheral equipment in 2007.

1. Strong reach and develop technology team, support machine upgrade continuously, support client strong technical support;

2. Rich experience in SMT Industry Line. ETON set up more than 10 years, we are leading manufacturer of SMT machine in China;

3. Strong production capacity, ETON have more than 50000 square meter Industrial park in Jiangxi Province, machine capacity more than 50 units/month;

4. Good and professional service. Provide engineer Door-to-door service, support video online training, video training share, free replaced machine core part during warranty. And also we could provide professional SMT line solution.

Service

Best service:

Before placing an order:

1) We will support professional advice on SMT line;

- We will recommend the best module according to the product;

- We will provide the best quotation at the ex-factory price;

After ordering:

- The machine will have a good test and aging before shipment;

- We support machine-free installation training, online training and video teaching in special time;

- We have a professional after-sales team, which can solve the problem in the first time;

- The whole machine is guaranteed for one year. During the warranty period, any parts that need to be repaired and replaced will be provided to customers free of charge;

- We have an opportunity for engineers to repair machines for free every year;

6) Visit customers regularly to understand the usage of the machine and collect customer feedback.

Package

FAQ

Do you have any customers in India?

Yes, we have many big clients in India, Turkey, Egypt and others.

Does the price include the spare parts(feeder and nozzle)?

Different clients has different requirements on spare parts, it is not fair to the clients to add in equivalent price for spare parts. So we don’t add the spare parts cost on price, and price is only for machine.

what’s the minimum quantity of an order for your company?

1 set machine are welcomed to order, mixed orders are also welcomed.

Q: If machine have any problem after I receive it , how can I do?

A: During the warranty period, we will replace it for you free, or we can arrange a process engineer to repair it for free