1. Dual-arm magnetic linear high-speed mounter for flexible strip(no wire), Producing 4 types materials at the same time capacity reach 250000 CPH.

2. Available for 5M, 50M or any length of flexible strip and Roll to Roll.

3. Dual arm four modules, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.

4. Calibration automatically, high precision, available for RGB.

5. Exclusive patent technology: Group to take and group to mount.

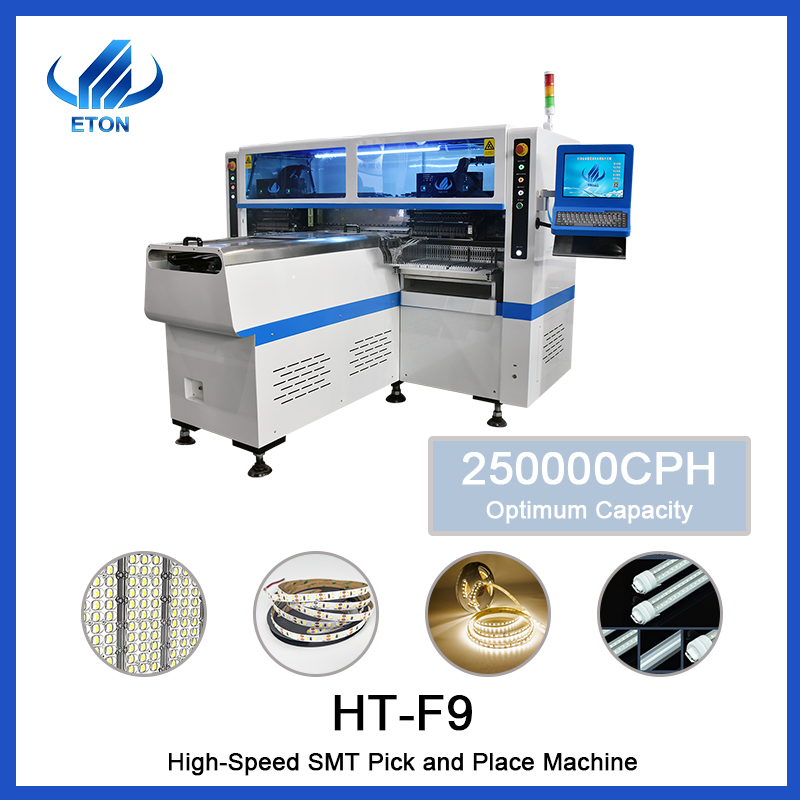

250000 CPH Flexible Strip Mounting Machine

Description

Production Introduction of Pick and Place Machine HT-T9

1. Dual-arm magnetic linear high-speed mounter for flexible strip(no wire), Producing 4 types materials at the same time capacity reach 250000 CPH.

2. Available for 5M, 50M or any length of flexible strip and Roll to Roll.

3. Dual arm four modules, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.

4. Calibration automatically, high precision, available for RGB.

5. Exclusive patent technology: Group to take and group to mount.

HT-T9 of Technical Parameter

|

Dimension |

3100*2300*1550mm |

|

PCB Size |

250*any length |

|

PCB Thickness |

0.5~5mm |

|

Mounting mode |

Group to take and group to mount |

|

Mounting precision |

±0.02mm (Repeat precision) |

|

Mounting height |

Standard:≤5mm |

|

Mounting speed |

200000~250000 CPH |

|

Components |

LED 3014/3020/3528/5050 and resistors, capacitors,bridge rectifiers etc. |

|

Components space |

0.5mm |

|

No.of feeders station |

68 PCS |

|

No.of head |

68 PCS |

|

Power |

AC 380V 50Hz |

|

Power consumption |

6 KW |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor and servo motor |

HT-T9 Picture

Application

Apply to 5M, 25M,50M or any length of flexible strip and Roll to Roll.

Production line Introduction

The semi-automatic production line

PCB Loader, conveyor, transplanting machine, buffer frame, semi-automatic printing machine, pick and place

machine, belt transport guide rail, reflow oven, PCB Un-loader.

The full-automatic production line

PCB Loader, conveyor, transplanting machine, buffer frame, automatic printing machine, pick and place machine, belt transport guide rail, reflow oven, PCB Un-loader.

Company Introduction

ETON is an industry and trade integrated company, with 14 years of R&D and production experience in the smt field.

ETON has an industrial park of more than 52,000 square meters in Jiangxi Province, with more than 500 employees and strong manufacturing capacity, We can produce more than 50 machines a month.

Package and Delivery of Pick and Place Machine

Service

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

FAQ