Description

Features

(1)machine highlights

High-speed Multi Modular Head: Adopt High-speed multi modular head,apply to ultra small chip 0201~40*40mm large Chip,wider component range.

Brand New Flight Vision Camera: Improve recognition performance, size up to 40mm*40mmapply to BGA or CSP etc.

Vacuum Sensing Device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product.

Ultra-high-speed Capability: Adopt High-end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum placement speed reach 40000 CPH.

(2)Flexible production

Fixed Flight Vision Recognition Camera(Option): Components with size less than 40*40mm or height less than 20mm can be used to high-speed and high-precision identification, IC tray feeder support(Option).

Intelligent Electric Feeder: Support YT series double head intelligent electric tape reel feeder by optically correcting the feeding position of the component,it can achieve stable,accurate and high-speed feeding.

(3)High reliability

Brand new self-developed high-precision placement head

High-speed precision head flight vision camera capture the image of placement

accordingly,improve the speed and accuracy of placement.The placement head adopt independent vacuum detection,improve placement performance.

Off-line programming,save time of changeover cycle.

Software Al intelligent learning function and automatic optimization function.

Technical parameter

|

model |

YT 101S |

|

PCB size |

MAX size: 500*350mm MIN size: 50*50mm |

|

PCB thickness |

0.5-4.5mm |

|

PCB clamping |

Cylinder clamping, track width adjustable |

|

rail |

Rail 1 is fixed |

|

system |

Windows 7 |

|

software |

R&D independently |

|

Production management MES system |

Customized(option) |

|

Off-line programming |

available |

|

No. Of camera |

2 set (digital camera) |

|

Head flight vision recognition component |

|

|

Vision alignment+ mark correction |

|

|

Repeat precision |

±0.02mm |

|

Mounting height |

≦20mm |

|

Mounting speed |

40000 CPH (optimum speed) |

|

Components range |

Min 0201-40*40mm packages and IC etc |

|

Power |

380AC 50HZ 4KW |

|

Operation environment |

23℃±3℃ |

|

Transmission direction |

Single (left-right, right-left) |

|

Transmission mode |

Online drive |

|

Position mode |

optical |

|

Air consumption |

0.4-0.6mpa()4-6kgf/cm2) 150N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 1 set |

|

|

X,Y,Z Axis drive way |

High end magnetic linear motor+ servo motor |

|

No. Of feeder station |

Station:16 pcs, tape reel packages 32 pcs |

|

No. Of heads |

10 pcs |

|

Feeding way |

Intelligent double head feeder |

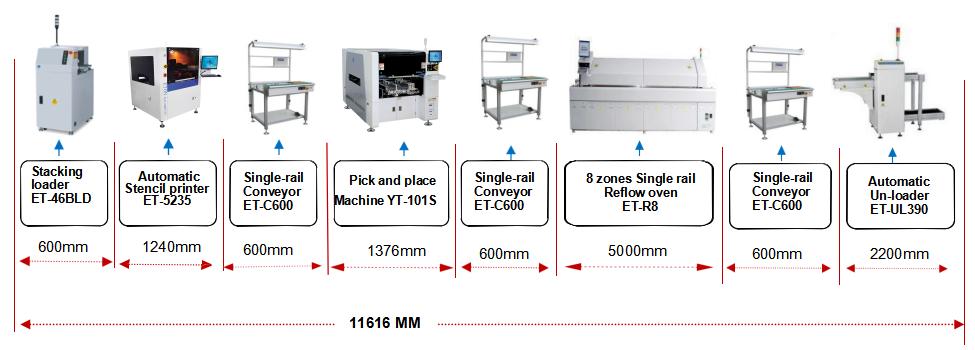

full-automatic production line

customers

Our products are exported to more than 30 countries & regions

Such as South Korea, Turkey, Egypt, India, Russia, America, Brazil, Tunisia, Poland, Lithuania, South Africa, Iran, Vietnam, Pakistan , Saudi Arabia, Uzbekistan, Nigeria , Germany, etc.

FAQ:

1.What are the main components the pick and place machine can mount?

It is available for all kinds of components, including LED chip, resistors, capacitors, IC,shaped component and so on.

2.Do you provide the complete production line machine?

Yes, of course. We provide the whole production line machine, including solder paste printer machine, conveyor, pick and place machine reflow oven.

3.How about the operating software?

Our software is R&D independently by ourselves.

4.Do you provide personal customization?

Yes, of course. contact the sales specialist to customize the equipment for you.

5.If I don’t know how to operate the machine what should I do?

Don’t worry about it. We will provide the detailed operation instructions, and part of area will provide oversea engineer teaches the operation door-to-door.

Maintenance period 1 year

- One year warranty, during warranty, any parts that need to be repaired and replaced will be free

Software and hardware lifetime maintenance

- Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates

Visit customers regularly and gather information

- Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time

Provide the latest information about technology and equipment

- We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

- We have some official site in India as Mumbai and New Delhi, also have site in Egypt. Turkey that can provide service timely with our engineers.

- According to your needs. dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

Contact me:

Whatsapp/Wechat/Tel: +8613823702684

Email: ivy@eton-mounter.com