- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 2 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

INTRODUCTION

E8s-1200 single-mode maglev multi-functional high-speed Mounter with 12 heads and 28 suction nozzles. The mounter speed can reach 45000cph per hour. The multi-functional mounter is suitable for mounting spherical bulbs, panel lights, downlights, street lights, display screens, circuit boards and other products. Exclusive patented technology: group take and paste, separate take and paste The minimum mounting 0402 components and the maximum mounting part range are 15mm. The high-end brand Hikvision camera and high-end linear motor are adopted, which makes the mounting accuracy higher and the machine life longer.

Technical parameter

|

Dimension(L*W*H) |

3150*2250*1650mm |

|

PCB Length Width |

Max:1200*300mm Min:100*100mm |

|

Mounting Mode |

Group picking and separate placing\separate picking and separate placing |

|

PCB Clamping |

Adjustable pressure pneumatic |

|

PCB Thickness |

0.5-5mm |

|

System |

Windows7 |

|

Software |

R&D independently |

|

No. of Camera |

4 sets of imported camera |

|

Mounting Speed |

45000CPH |

|

Components |

LED , capacitors, resistors, IC, shaped components, etc. |

|

No. of Feeders Station |

28PCS |

|

No. of nozzles |

12PCS |

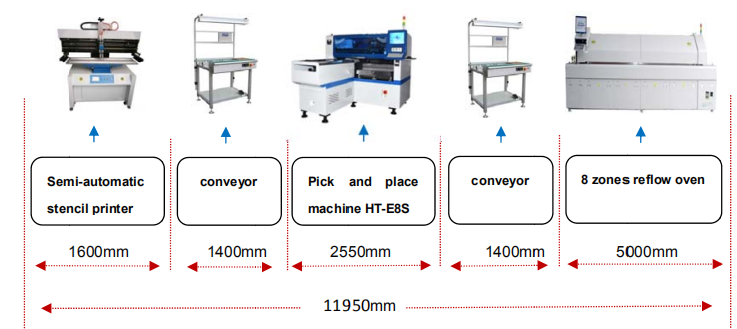

Introduction to machine functions of SMT production line

|

Product Name |

function |

|

Semi Stencil printer machine |

A device that leaks solder paste or patch glue onto the PCB pad to prepare for component welding |

|

Conveyor |

It is used for the connection between SMT production lines. It can also be used for buffer, inspection, test of PCB or manual insertion of electronic components |

|

Pick and place machine E8S-1200 |

Accurately install the surface assembled components to the fixed position of PCB |

|

Reflow oven |

Melt the patch adhesive so that the surface assembled components and PCB board are firmly bonded together |

E8S-1200 SEMI-AUTOMATIC PRODUCTION LINE

WHY choose us?

Shenzhen ETON automation equipment Co., Ltd., founded in 2011, is a manufacturing and process solution provider focusing on the R &D, production, sales and service of SMT high-speed mounter and SMT peripheral automation equipment.

With strong production capacity, ETON has an industrial park of more than 50000 square meters in Jiangxi Province, 7 buildings, more than 300 employees,supporting OEM & ODM, and the mechanical capacity is more than 50 sets / month

It has its own independent R & D team and more than 20 years of R & D experience.

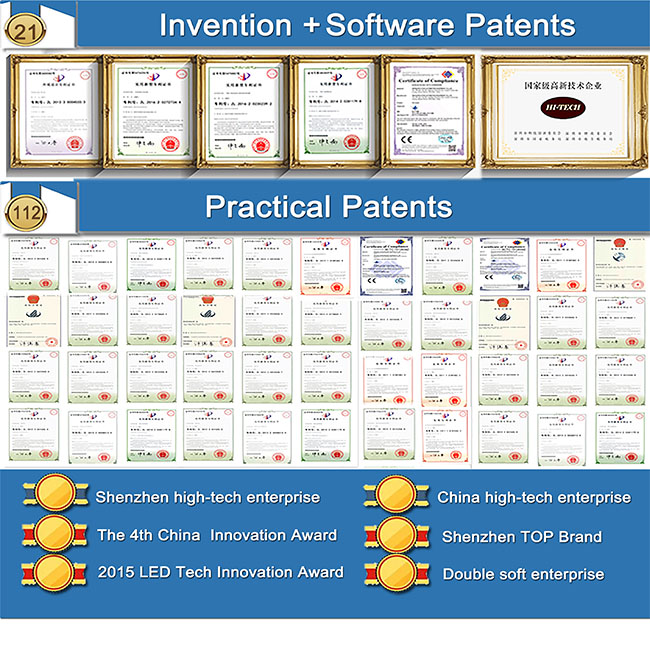

certificate

The research and development of the machine has been guaranteed and obtained patent recognition. It has the world’s first invention patent, 9 invention patents, 12 software copyrights and 112 utility model patents.

FAQ

Q:What is the delivery date?

We will deliver the goods after 30 days’ deposit.

Q:Is electrical control developed independently?

Yes, the electrical control is by ourselves and have exclusive patent technology.

Q:Are you a manufacturer or trading company?

manufacturer. We have our own industrial park