Description

Product description:

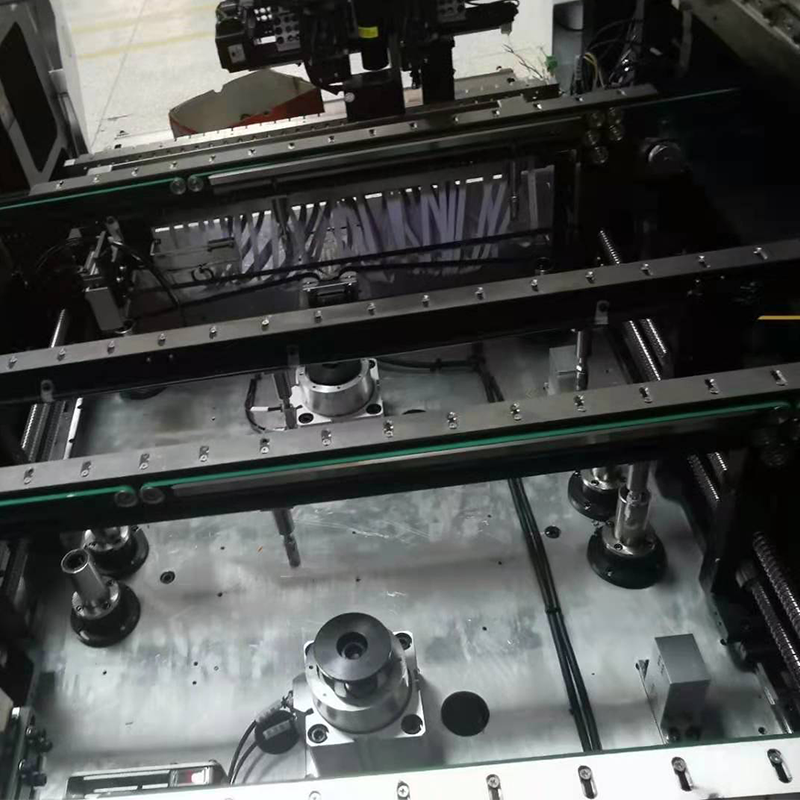

1.T9-2S machine is one of the newly launched value series products from ETON. Producing with 4 types materials at the same ,improving production efficiency.

2.Under optimal conditions, the production capacity can reach 500000CPH,which the mounting speed has already broken the world record.

Machine features:

1.Component picking position can be adjusted according to PCB pad pitch,min 6.5mm. Apply to LED 3014/3020/2835/5050 resistor , capacitor, bridge rectifier etc.wide component range.

2.Unique Design Component Leaking Detection And Individual Component Refill

Function :Recognition camera record the component leaking position of PCB,and fill the missing component accordingly.

3.The placement head adopt the method of two times picking and once placing. The placement time greatly minimized with the improved placement way, excellent optimum capacity reach 500000CPH.

4.Adjust the conveying platform according to various roll to roll strip, range 250±10mm,the max length range is 1m per cycle.

5.136 placement heads, adopted group picking and group placing,so as to realize the function of two time picking and once placing.

6.Adopted Intelligent electric feeder with double motor feeding way.

Machine main parameter:

|

Model |

T9-2S |

|

Dimension(L*W*H) |

3454*3035*1777mm |

|

Weight |

3100kg |

|

PCB length width |

250mm(±10)*any length |

|

PCB thickness |

0.5~0.5mm |

|

Mounting way |

Group to picking and group to mount |

|

Mounting mode |

Double rail+four group of placement heads |

|

Mounting height |

≤5mm |

|

No.of camera |

10PCS |

|

Vision alignment, Mark correction |

|

|

Components |

LED 3014/3020/3528/5050/and resistor,capacitor, bridge rectifiers etc. |

|

Power consumption |

9.6KW |

|

Optimum Mounting speed |

500000CPH |

|

No. Of feeders station |

Double side:136 PCS(single side:68pcs) |

|

No. Of head |

Double side:136 PCS(single side:68pcs) |

|

X,Y Axis drive way |

High-end magnetic linear motor+Servo motor |

|

Feeding way |

Intelligent electric feeder with double motor |

Application:

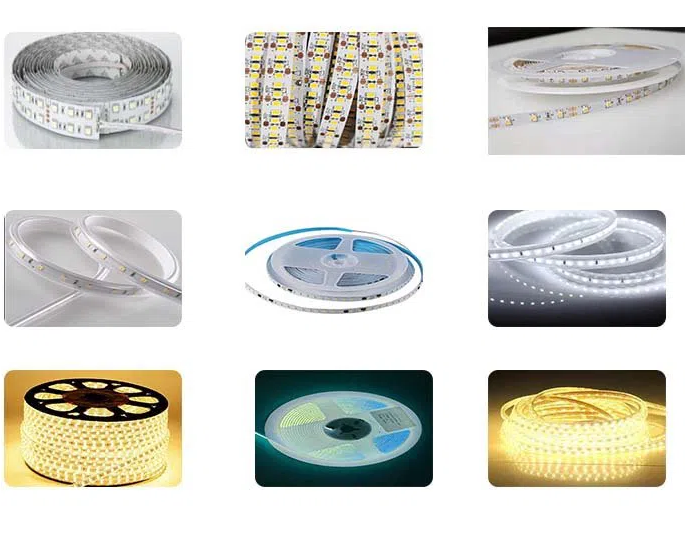

T9-2S Machine apply to 5/10/50/100/150/200 m and flexible light strips of any length,roll to roll strip.

Exhibition:

As a large company, our company participates in many domestic and foreign exhibitions every year, except during the epidemic:

Domestic Exhibition: Guangzhou international lighting Exhibition; Shanghai Munich Exhibition; Chongqing LED Light Exhibition, etc.

Overseas Exhibition: India Delhi Exhibition, India Mumbai Exhibition, Pakistan Exhibition, Egypt Exhibition, Tunisia Exhibition, Thailand Exhibition, etc.

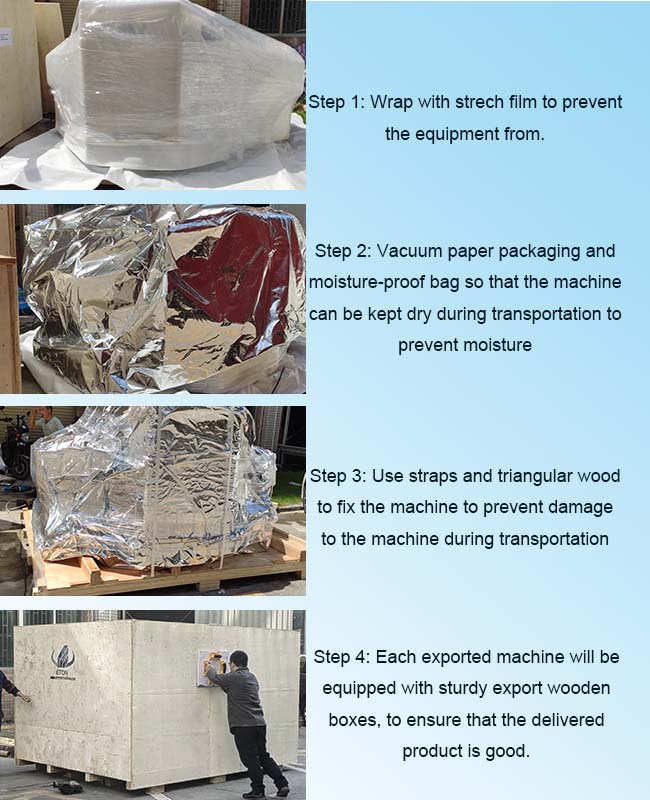

Packing:

Packing: standard is plastic film wrap the LED SMT machine, then load into one 20″ container; Wooden box packing can be customized.

Delivery: 35-40 days after 30% T/T prepayment, buyer should come to inspect when we do test running, after testing, pay the 70% balance before delivery.

FAQ:

1.Why should you buy from us not from other suppliers?

We are high-tech professional manufacturer of SMT machine with more than 10 years with good quality and reputation. We have rich experience in helping client to start new factory and new line. “Professional, high-effective, cost-saving” are our advantages.

2.Is your software interface in English?

English interface and Chinese interface are both available.

3.This is the first time I use this kind of machine, is it easy to operate?

Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

4.Does the price include spare parts(nozzle and feeder)

Different client has different requirements on spare parts, it is not fair to clients to add In equivalent price for spare parts. So we don’t add the spare parts cost on price. And price is only for machine .