Description

Product description:

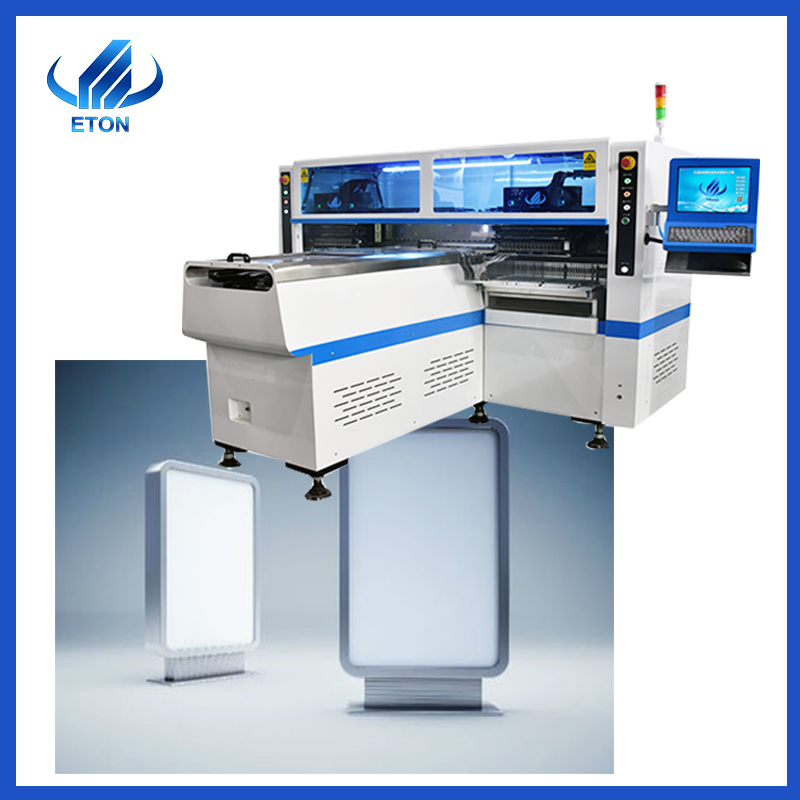

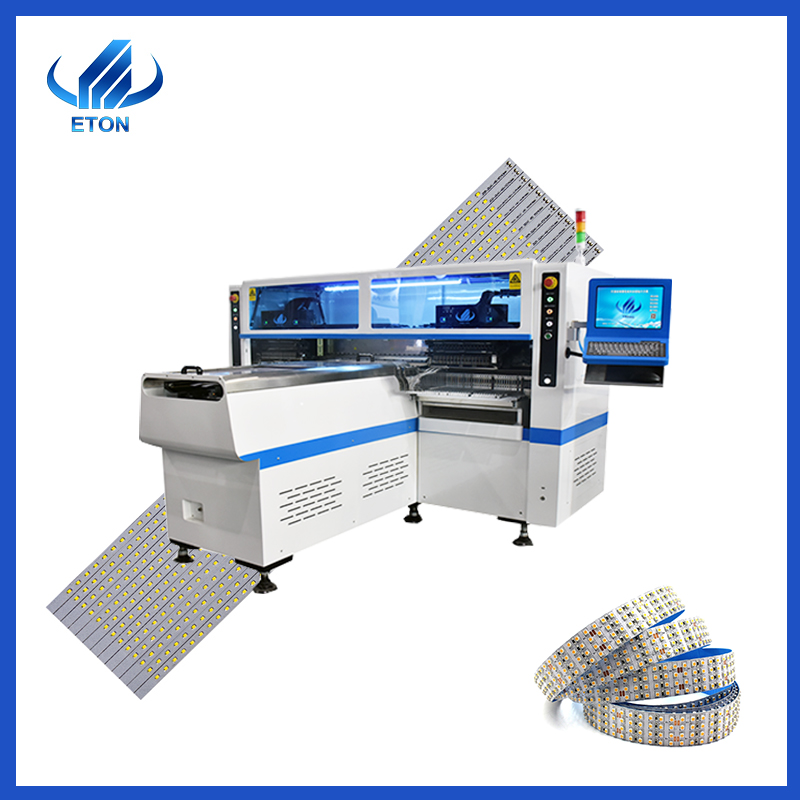

1.YT 202S is one of the newly launched YT series products from ETON. The dual-module placement machine can produce two identical PCB boards at the same time, improving production efficiency.

2.Under optimal conditions, the production capacity can reach 80000CPH, and the precision is very high, and the minimum mounted components can reach 0201.

3.The ultimate host with three characteristics, a new fixed flight identification camera, with identification components corresponding to 40*40mm, can identify ball grid arrays such as BGA or GSP.

4.The feeder is equipped with a special docking cart The double-sided station has 32PCS, which can load 64 trays of materials, and the single-sided station has 16PCS and can load 32 trays of materials.

Double-head intelligent feeder, one equivalent to the original two feeders, realizes high-speed and stable feeding through optical correction.

Support multi-layer IC Tray feeder, realize easy completion of alternate work with docking cart.

Machine main parameter:

|

1.PCB |

|

Suitable for max PCB size is 500*450mm, mini size is 50*50mm PCB using cylinder clamping, track width adjustable for clamping The Rail 1 is fixed but other is flexible The PCB thickness is 0.5-4.5mm |

|

2.Camera |

|

The No.of camera is 4 sets digital camera, head flight vision recognition component, vision alignment, mark correction |

|

3.Precision |

|

The repeat precision is ±0.02mm, support for 0201-40*40 IC |

|

4.Component range |

|

Mini 0201-40*40mm package and IC, apply to BGA, CSP etc. Max mounting height is 20mm |

|

5.Mounting speed |

|

The optical speed is 80000 CPH with 20 mounting heads |

|

6.Feeding way |

|

Intelligent double head feeder |

SMT Production line:

ETON over decades years experience in SMT field, so we are very professional to provide whole line solution.

Automatic stencil printer machine with pick and place machine, loader, conveyor, unloader, reflow oven to be one automatic line.

Automatic line save much labor cost compared with the semi automatic line, also with higher printing precision could produce high quality electrical products. Here are the YT202S Pick and place machine Semi-automatic SMT line solution layout.

Company profile:

ETON is China’s largest manufacturer of SMT machine, industrial park more than 50000 square meters.

ETON has decades experience R&D experience in SMT industry equipped with core technology.

ETON occupied over 80% big led lighting industry market, machine hot sell to more than 20 countries.

ETON R&D Chinese first automatic stencil printer machine for roll to roll 100 m led strip light.

ETON R&D super high speed pick and place machine, 500000 CPH, fastest in all over the world.

Packing:

All our machines will be inspected and tested again before shipment to ensure the quality of the machines. For packaging, we are also very strict in every link.

Step 1 Plastic film packing and Foam cotton packing:

preventing the dust and water ,protecting from hitting and shaking while ship

Step 2 Vacuum tin foil packing:

protection from oxidation and water, keep dry of machine during transportation

Step 3 Stand wooden box packing:

Prevent the machine from being damaged and facilitate transportation

FAQ:

1.How is the training?

After purchasing our products, you can send your engineers to study in our factory, or we can send our engineers to your factory to train your staff for you .

2.Do you have a product certification certificate?

Our products have CCC, CE, SRIA certification.

3.How can I buy this machine from you? ( Very easy and flexible )

(a).Consult us about this product on line or by e-mail.

(b).Negotiate and confirm the final price , shipping , payment methods and other terms.

(c).Send you the proforma invoice and confirm your order.

(d).Make the payment according to the method put on proforma invoice.

(e).We prepare for your order in terms of the proforma invoice after confirming your full payment

4.how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;