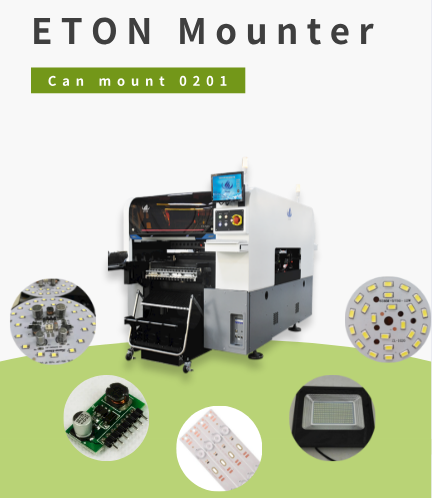

YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

Product description

YT 202S is one of the newly launched YT series products from ETON. The dual-module placement machine can produce two identical PCB boards at the same time, improving production efficiency.

Under optimal conditions, the production capacity can reach 80000CPH, and the precision is very high, and the minimum mounted components can reach 0201.

Feature

|

The ultimate host with three characteristics, a new fixed flight identification camera, with identification components corresponding to 40*40mm, can identify ball grid arrays such as BGA or GSP. |

|

Vacuum sensing device, each suction nozzle has an independent detection function, which improves the stability and reliability of the equipment. |

|

Ultra high speed mounting capacity of products at the same level. |

|

Support YT series universal double head intelligent feeder, and realize stable and accurate feeding by optically correcting the feeding position. |

Function

|

Achieve stable production. |

|

Adopt new self-developed high-precision mounting head. |

|

High speed and high-precision head flying racket for reclaiming to improve mounting speed and accuracy. |

|

Equipped with independent vacuum detection function of suction nozzle to better ensure the stability of reclaiming. |

|

Offline programming function to shorten line change cycle. |

|

The software has AI intelligent learning and automatic optimization functions. |

Feeding system

The feeder is equipped with a special docking cart The double-sided station has 32PCS, which can load 64 trays of materials, and the single-sided station has 16PCS and can load 32 trays of materials.

Double-head intelligent feeder, one equivalent to the original two feeders, realizes high-speed and stable feeding through optical correction.

Support multi-layer IC Tray feeder, realize easy completion of alternate work with docking cart.

Transport track system

Double arms and double heads, flexible PCB processing capability, double rail structure, can realize the production of a large PCB board

Modular placement head and various production modes, flexible assembly line.

FAQ

Q1:How to train our employees after buying the machine?

A:First of all, we have service points in some countries. If the customer’s company is located in these countries, we can provide on-site training and installation. If not, please don’t worry. We will help your employees master the machine through online training, or if circumstances permit, we can send employees to your factory for training.

Q2:Is your machine difficult to master?

A:No, it’s not difficult at all. Take our previous customers for example. They can learn it in five days at most.

Q3: What are the terms of payment?

A: FOB Shenzhen is OK

Q4: Why are your products more expensive than others?

A:I am more expensive than others because we use imported brand parts to ensure the quality. I think we should see the longer-term value brought by our products, such as the market occupied by the increase of output.