- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 2 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

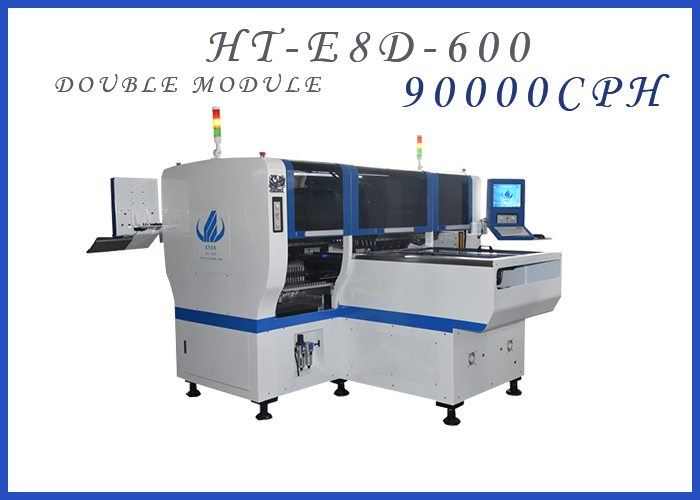

HT-E8D-600 introduction

Ht-e8d-600 dual-mode maglev multifunctional high-speed Mounter dual-mode group has 12 suction nozzles in each group, a total of 24 suction nozzles, and Feida dual-mode group has 48. Maglev linear motor has longer service life and higher precision. The optimal production capacity of high-speed Mounter per hour is 90000 CPH. It has two systems and can produce two different products at the same time. The multi-functional mounter is widely used in the mounting of various drives, power supplies, circuit boards, lenses, linear bulbs, home appliance control boards and other products. Exclusive patented technology, electronic Feida feeding system, flight recognition vision.

Technical parameter

|

Model |

HT-E8D-600 |

|

Dimension |

|

|

Length |

1950mm |

|

Width |

2250mm |

|

Height |

1650mm |

|

Total Weight |

2200kg |

|

PCB |

|

|

PCB Length Width |

Max:600*300mm Min:100*100mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Adjustable pressure pneumatic |

|

Mounting Mode |

Group picking and separate placing\separate picking and separate placing |

|

O.S. |

|

|

System |

Windows7 |

|

Software |

R&D independently |

|

Display |

Touch screen monitor |

|

Input Device |

Keyboard, Mouse |

|

Vision System |

|

|

No. of Camera |

4 sets of imported camera |

|

Vision for the flight identification, MARK correction |

|

|

Mounting Precision |

±0.04mm |

|

Mounting Height |

<15mm (Automatic Changing) |

|

Mounting Speed |

90000 CPH |

|

Components |

LED , capacitors, resistors, IC,shaped components, etc. |

|

Components Space |

0.2mm |

|

No. of Feeders Station |

48 PCS |

|

No. of nozzles |

24 PCS |

|

Power |

380AC 50HZ |

|

Power Consumption |

8 KW |

|

Operating Environment |

23℃±3℃ |

|

Conveyor transmission |

Max length :600 mm |

|

Transmission Speed |

>1000mm/sec |

|

Transmission Direction |

Both direction (option) |

|

Transmission Mode |

Auto online drive |

|

Air supply |

0.4-0.6mpa (4-6kgf/cm2)300N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 2 set |

Independent research and development by ETON |

|

X,Y,Z Axis Drive way |

High-end magnetic linear motor + Servo motor |

|

Feeding way |

Electric feeder with double motor |

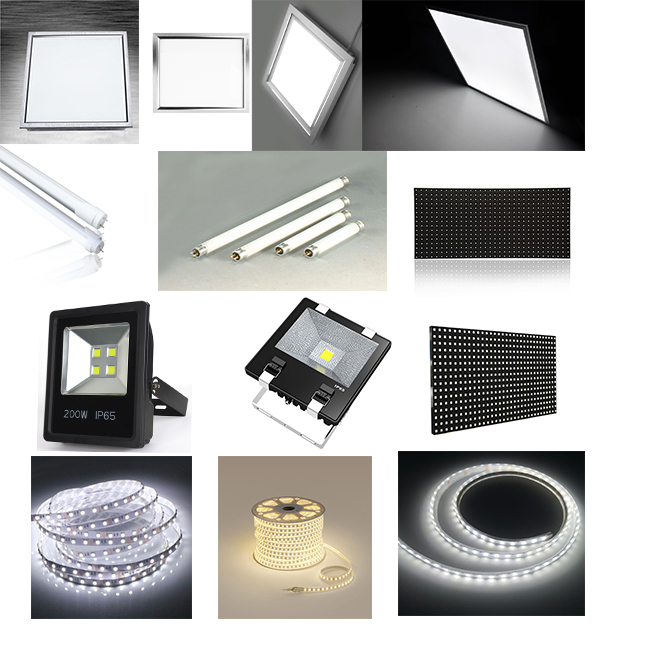

APPLICATION

Application:bulbs, panel lights, drivers, downlights, DOB,streetlight electric board and so on

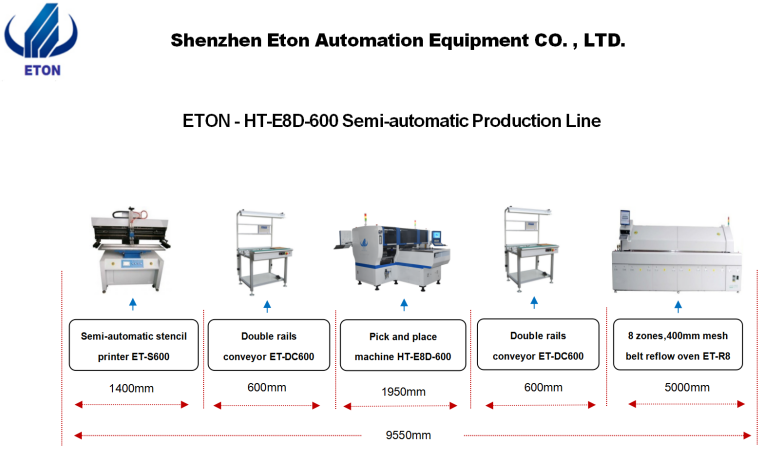

SMT LINE

PACKING

We use vacuum wooden box packaging

Step 1:Film packaging

Step 2:Vacuum packing

Step 3:Wooden box packing

FAQ

Q: Are you a trade company or a manufacturer?

We are an professional manufacturer specialized in Screen Printer,SMT Machine, Pick and Place Machine, Reflow Oven, SMT Production line and other SMT Products.

Q: What is your delivery date?

The delivery date is about 20 days upon the full payment.

Q: What is your payment terms?

100% payment before delivery or 50% deposit in advance and the rest before shipment.