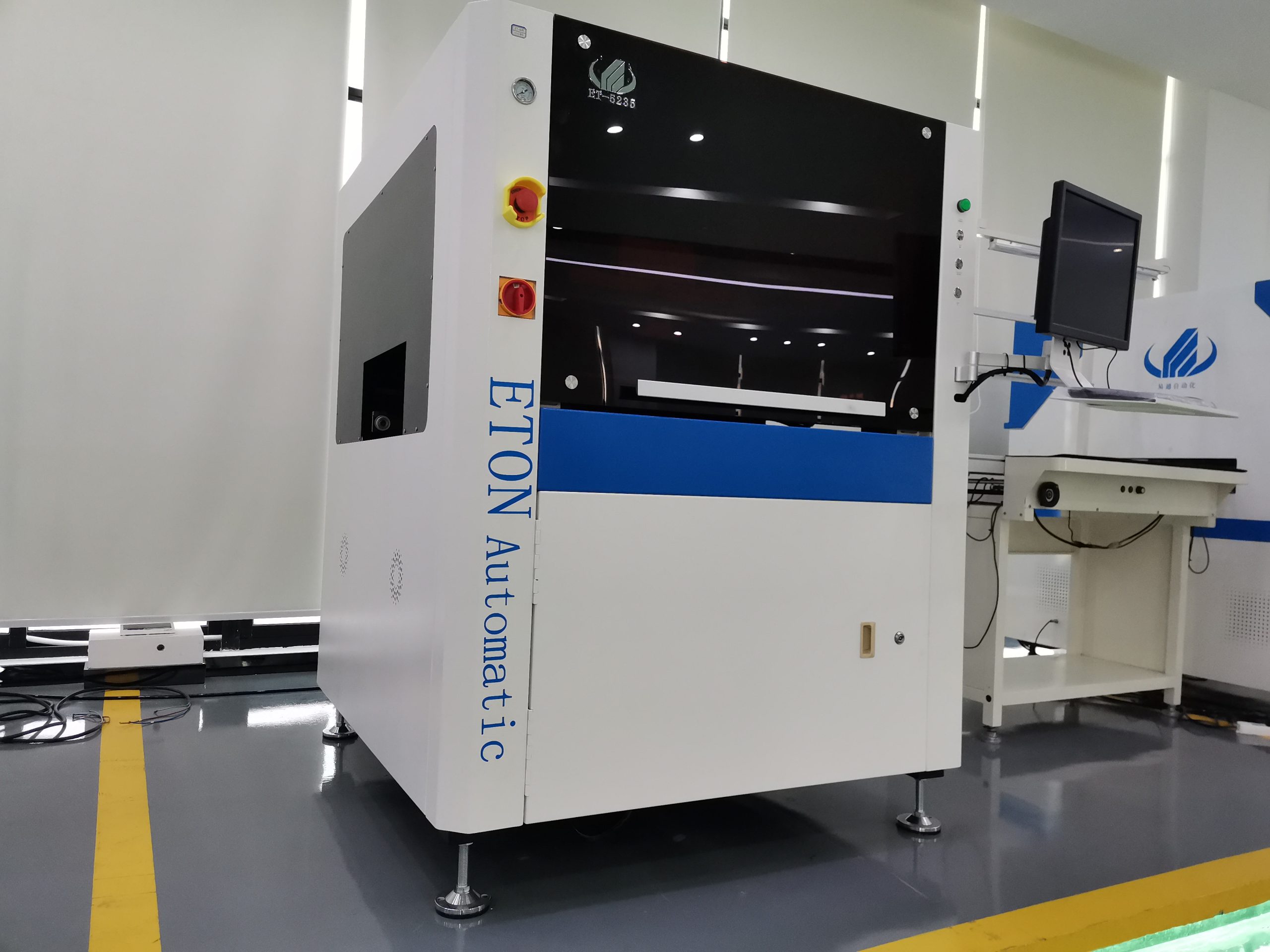

Description

PCB Transport and Clamping system:the PCB loading direction can be selected and combined freely,unique crafted internal gear conveyor belt to prevent jamming, adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh

Scraper system: cast aluminum scarper beam to ensure smoother running of scarper, programmable suspension self-adjusting stepper motor drives print head,embedded scale, never fall of.

Operation interface: easy to learn and easy to use friendly operation interface, make program files with teaching and navigation functions, with prompts for each step,one key switch between Chinese and English,with operation log, fault record analysis and diagnosis and other functions

Image and optical system:X,Y axis adopts high-precision grinding ball screw, driven by servo motors at both side

Stencil positioning system:

Arch bridge- shaped suspension hanging direct-connect scraper;The size of steel mesh is universal, with good and wide applicability;Segmented fixed steel mesh frame

|

Model |

ET5235 |

|

|

Screen Frames |

Max Size |

737mm |

|

Min Size |

470mm |

|

|

Thickness |

25~40mm |

|

|

PCB Size |

Max:520*350mm;Min:50*50mm |

|

|

PCB thickness |

0.1~0.6mm |

|

|

Transport height |

900±20mm |

|

|

Transport direction |

Max 1200mm/s Programmable |

|

|

PCB Board location |

Support system |

Magnetic Pin/Up-down table adjusted by manual |

|

Clamping system |

Unique top flattened ,side clamping |

|

|

Print head |

Two independent direct- connect motor- drive print heads |

|

|

Squeegee speed |

6~300mm/sec |

|

|

Squeegee pressure |

0~10kg/cm2 |

|

|

Squeegee type |

Steel scraper(Standard), PV scraper(Option) |

|

|

Stencil separation speed |

0.1~20mm/sec Programmable |

|

|

Cleaning system |

Dry,Wet,Vacuum(Programmable) |

|

|

Printing accuracy |

±0.025mm |

|

|

Cycle time |

≤9s(Exclude printing&cleaning) |

|

|

Product changeover |

<5Min |

|

|

Control method |

PC control |

|

|

Dimension |

1240(L)*1450(W)*1650(H)mm |

|

|

Weight |

Approx: 700kg |

|

|

PCB transfer overhead height |

10mm |

|

|

Air required |

4.5~6kg/cm2 |

|

1.We have our own industrial park to produce and manufacture machines, at the same time, we are equipped with all strong R&D teams, focusing on the research and development of SMT machines and equipment

2.We occupy 80% of the LED light customers in the market, and at the same time, our products have been widely recognized and approved by customers

3.We have engineers and offices abroad, and can provide machine installation and on-site service and training free of charge

4.The software of our machine is independently developed and can provide free upgrades for life. Some hardware of our machine is made of well-known brands at home and abroad to ensure the quality of the machine

ETON,as the top of SMT equipment manufacturer ,we cooperated with many big foreign companies and brands, and our products have been well received and recognized by domestic and foreign customers.

We are not only a top chip mounter manufacturer, but also a manufacturer of some peripheral equipment, not only can provide pick and place machine, but also can provide you with printing machine, glue dispenser, conveyor, transfer machine, reflow soldering machine, can Together with the placement machine to form a production line, improve the production efficiency of products.

We have to pack in vacuum wooden cases to ensure the safety of the goods in the transportation process. Our packaging process is in the charge of professionals, and foreign trade salesmen track the delivery throughout the process.

Step 1 Plastic film packing and Foam cotton packing:

preventing the dust and water ,protecting from hitting and shaking while ship

Step 2 Vacuum tin foil packing:

protection from oxidation and water, keep dry of machine during transportation

Step 3 Standwooden box packing:

Prevent the machine from being damaged and facilitate transportation

Finally,professional industrial drivers team send the wood box to the shopping container safety.

1.Why should you buy from us not from other suppliers?

We are high-tech professional manufacturer of SMT machine with more than 10 years with good quality and reputation. We have rich experience in helping client to start new factory and new line. “Professional, high-effective, cost-saving” are our advantages.

2.Is your software interface in English?

English interface and Chinese interface are both available.

3.This is the first time I use this kind of machine, is it easy to operate?

Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.