Dual arm professional high-speed mounter, mounting 2-4 types of materials at the same time capacity reach 180000 CPH. Apply to the 0.6m, 0.9m, 1.2m rigid PCB and 0.5m, 1m LED flexible strip, producing with 4 types materials at the same time with high capacity, available for board with any proportion of LED chip and resistor.

Available for RGB Surface mounted machine

Description

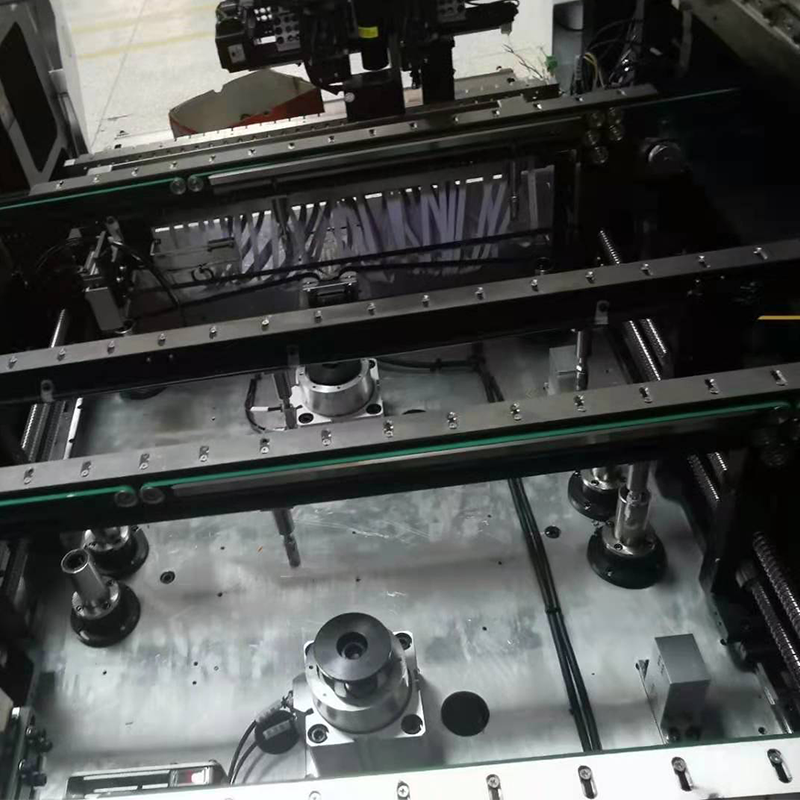

Dual arm professional high-speed mounter, mounting 2-4 types of materials at the same time capacity reach 180000 CPH.

- Apply to the 0.6m, 0.9m, 1.2m rigid PCB and 0.5m, 1m LED flexible strip, producing with 4 types materials at the same time with high capacity, available for board with any proportion of LED chip and resistor.

- Dual arm four module, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.

- Calibration automatically, high precision, available for RGB.

- Exclusive patent technology: Group picking and group mount placing.

- IPC9850 capacity: 150000-180000 CPH

Machine parameter

|

Model |

HT-F7S |

|

Dimension |

2700*2300*1550mm |

|

Total weight |

1700kg |

|

PCB length width |

Max: 1200*330mm Min: 100*100mm |

|

Mounting speed |

150000-180000 CPH |

|

No. of feeders station |

68 PCS |

|

No. of head |

34PCS |

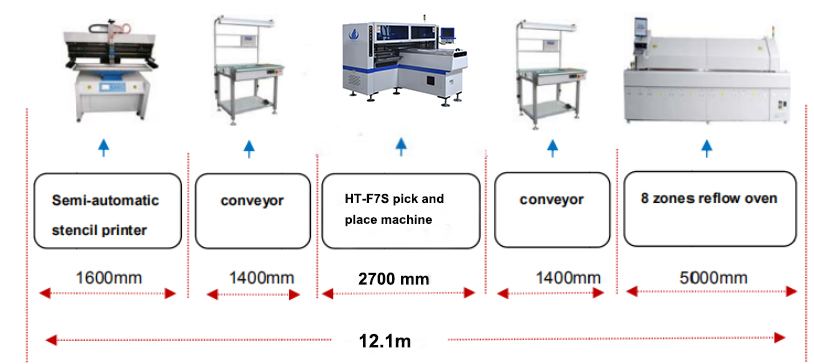

The blowing is the function of each machine:

- Semi auto stencil printer is aim of leaking solder paste or patching adhesive onto the solder pad of PCB to prepare for the welding of components;

- Pick and place machine is to mount light beads or other surface mounted components at the designated position of PCB board;

- Reflow oven is to melt the solder paste to fix and bond the components and PCB board.

- Conveyor is used for the connection between SMT production lines, as well as buffering, testing, testing PCB boards or manual plug-in of electronic components;

Our products had exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:

SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

Our package step is follow the blowing:

STEP 1: Film packaging to prevent the dust and water;

STEP 2: Packing in a foam cotton stretch a film to protect the outside of the machine;

STEP 3: Vacuum paper package and moisture proof bag, to keep dry during the transportation;

STEP 4: Equip with sturdy wooden boxes to ensure the safety of the machine, then transportation by trucks to the specified port.

Delivery: by sea, air, land transport.

Service

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

- Is the machine easy to operate?

- Yes, our machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

- What services can you provide?

- We provide whole line solution for our clients;

- We have local engineers in India, Egypt, Turkey. As long as you buy the machine, we will arrange engineers to install, debug and training you for free, until you learned how to operate the machine, our service is very convenient;

- We also have Chinese engineers which provide online services to operate the machine to solve the problems with the machine;

- We will visit our clients for twice a year to operate the machine and view the status of the machine;

- Our clients enjoy a free up grade of the machine.

- How many hours does the machine can operate per day?

- Machine can work whole day. But for longer using life, we suggest you to have 1 hour or 2 hours off per day.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com