Description

Machine main part

The brain of the host machine escalates the feedback and processes it , then sends out instructions.

All the circuits of the electric box machine are integrated in the electric box. After the external power is connected, the running process of the machine is controlled together with the host machine.

The tank chain includes the wire to ensure that it moves, reduce wear and extends working life.

Head, suction nozzle can be installed to take material.

Feeder station, which feeders are placed.

Features

- Multifunctional pick and place machine, suitable for mounting LED chip, capacitors, resistors, IC, shaped components, lens, etc.

- Vision system, four cameras, high precision mounting

- PCB length width: max 450*350mm min80*80mm

Machine main parameter

|

Dimension |

1200*1930*1500mm |

|

Total weight |

2500kg |

|

PCB thickness |

0.1-6mm(if <0.6 need jig) |

|

PCB clamping |

pneumatic |

|

Camera |

4 pcs |

|

Power |

AC 380V |

|

Power consumption |

6KW |

|

Component space |

0.2mm |

Application

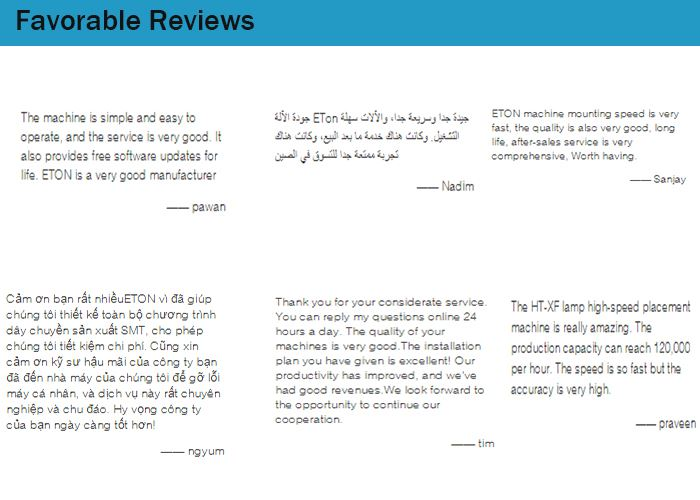

Favorable Reviews

This is an evaluation of our service, product quality and the company by customers from different countries

FAQ

Q: About technical offer

A: As for machine operation, we will arrange engineers to go to your factory for installation and teaching after you buy our machines.

If you have engineers who have been involved in the installation of SMT equipment, we can teach you how to install it online.

Q:How can we buy from us?

A: Pick and place machine, smt production line, stencil printer, reflow oven, load/unload machine, feeder,nozzle,etc.

Q: What service can we provide?

A:1.Free install, debug and train

2.Software free upgrade

3.Maintenance period: 1 year

Q: Do you sell nozzles and spares?

A:Yes, we do sell nozzles and feeders, if you need any spares, just let us know.