Description

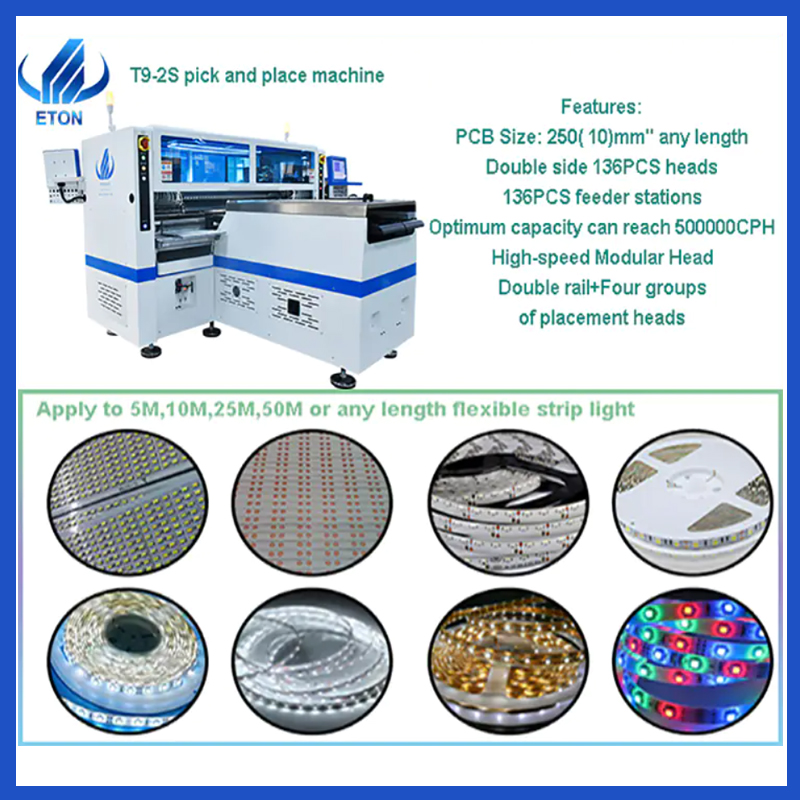

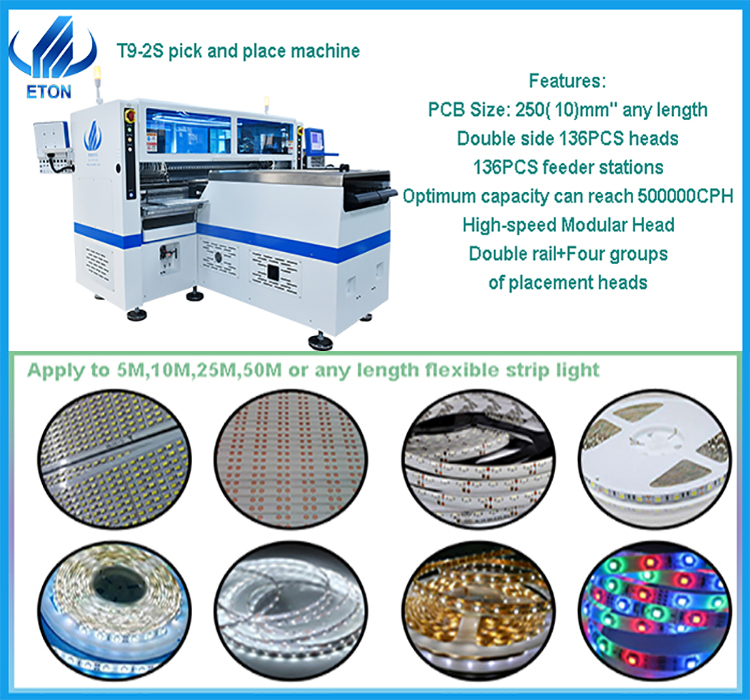

Production Introduction of Pick and Place Machine T9-2S

- High-speed Modular Head, ETON Tech Adjustable Placement Head.

- Apply to 3014/3020/2835/5050 resistor,capacitor,bridge rectifier etc.

- Component picking position can be adjusted according to PCB pad pitch, min 6.5mm.

- Unique Design Component Leaking Detection And Individual Component Refill Function: Recognition camera record the component leaking position of PCB,and fill the missing component accordingly.

- Ultra-high-speed Capacity: The placement head adopt the method of two times picking and once placing. The placement time greatly minimized with the improved placement way, excellent optimum capacity reach 500000CPH.

- Adjust the conveying platform according to various roll to roll strip,range 250士10mm,the max length range is 1M per cycle.

- The distance of feeder station can be flexibly adjusted to achieve group picking and group placing,so as to realize the function of two time picking and once placing.

- The range of feeding station is double of placement head,can produce four kinds of materials at the same time.

- Intelligent electric feeder,supporting high-speed machine series.

- Flight recognition camera,no pause to detect the presence or absence of components,component adsorption state,prevent placement errors.

- Automatic production with identification data,correction and fill missing component automatically.

- The clamping rod is driven by the air cylinder to correct the materials taken by mounting head.

- With the function of filling missing component automatically, realize Industry 4.0 Unmanned Workshop. Compliant with CE standards.

T9-2S of Technical Parameter

|

Dimension |

3454*3035*1777mm |

|

PCB Size |

250(±10)mm*any length |

|

PCB Thickness |

0.1~0.5mm |

|

Mounting way |

Group picking and group placing |

|

Mounting precision |

±0.05mm |

|

Mounting height |

≤5mm |

|

Mounting speed |

Double side:500000CPH Single side:250000CPH(Optimum speed) |

|

Components |

LED 3014/3020/2835/5050 and resistors,capacitors,bridge rectifiers etc. |

|

Mounting mode |

Double rail+Four groups of placement heads |

|

No.of feeders station |

Double side:136PCS(single side:68PCS) |

|

No.of head |

Double side:136PCS(single side:68PCS) |

|

Power |

380AC 50Hz |

|

Power consumption |

9.6 KW |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor and servo motor |

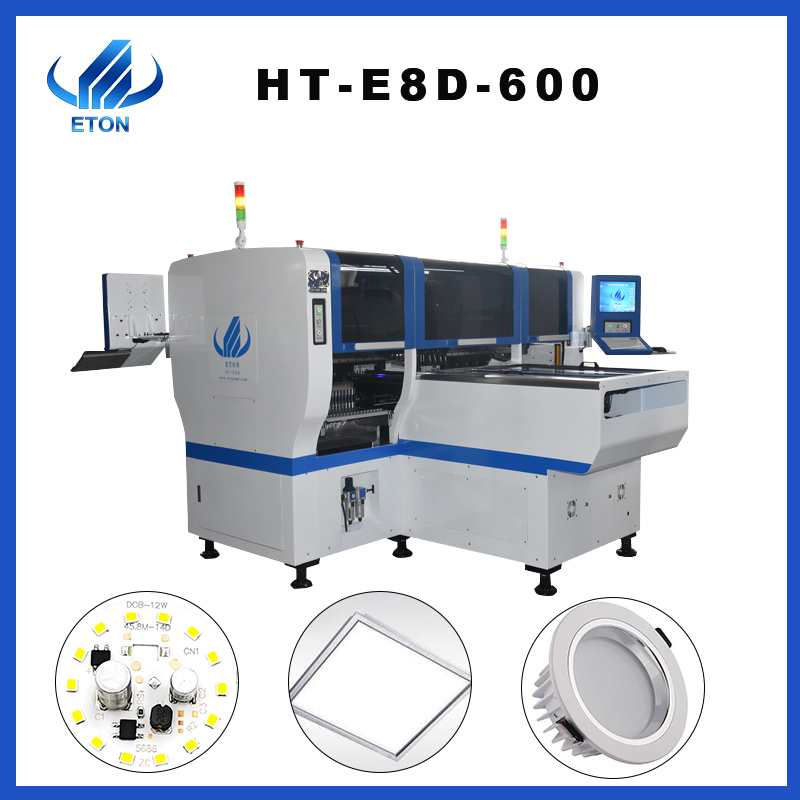

T9-2S Picture

Application of HT-T9-2S

Apply to 5M,10M,25M, 50M or any length of flexible strip and Roll to Roll.

Company Introduction

Shenzhen ETON Automation Equipment Co.,Ltd. Was founded in 2011. It is a manufacturing and process solution provider focusing on R&D, production, sales and service of SMT high-speed pick and place machine and SMT peripheral automation equipment. The company has SMT high-speed pick and place machine division, precision solder paste stencil printer division, high-speed precision dispensing equipment division, and SMT peripheral automation equipment division.

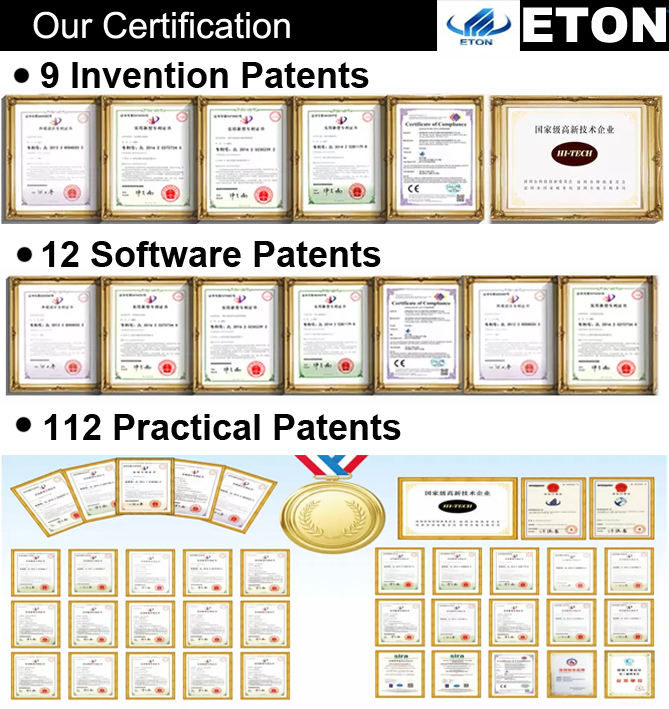

Certification

We are high-tech enterprise with CE,SIRA,CCC ,ISO awarded as “Well-know brand” and many technology patents, we got 9 invention patents, 112 practical patents,12 software patents and have rich experience(more than 10 years) in LED light production line program.

Package and Delivery of Pick and Place machine

All machines are packed with vacuum and wooden packing like the one in the pictures.

Step 1. Film packaging

Prevent the machine from dust ,water,crash and shaking.

Step 2. Add foam+film packaging

Double safe protection,Prevent the machine from crash and shaking.

Step 3. Unique tin foil packaging

Add tin foil packing can prevent the film from scratch broken.

Step 4. customized Strong wood carton packing

The customized strong wood packing for ocean ship,The machines are fix in the wood carton, effectively prevent collision and shock.

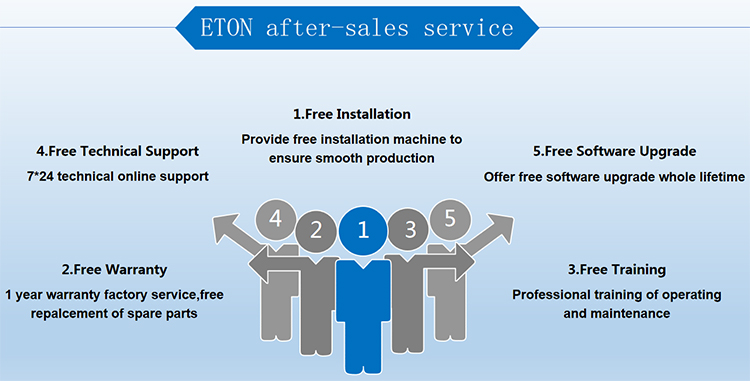

Our after-sales service of Pick and Place Machine

We provide send Free parts send to you in machine warranty period,and our engineers will visit to your factory help you to solve your machine’s problem.

Engineer site service installation and training.

After learning to maintain and use, you will be satisfied with our service.

Maintenance Period: 1 year. (whole machine, any parts need to be repaired or replaced will be free)

Upgrade the software will be free.

Visit customer regularly and gather information.

Provide latest information about technology and equipment.

Q: It’s hard to use the machine?

A: No, not at all. For our previous clients, at most 5 days is enough to learn to operate the machines.

Q: Does your machines have quality certificates?

A: We are high-tech enterprise with CE,SIRA,CCC ,ISO awarded as “Well-know brand” and many technology patents, and have rich experience(more than 8 years) in LED light production line program.

Q: What’s the terms of payment? What about the trade term?

A: T/T is OK. You can choose FOB Shenzhen.

Q: What’s your delivery time?

A: Usually 30 days after deposit, if we have inventory, the time can be brought forward.

Q: Is there any quality guarantee?

A: We stick to quality first, client-oriented, Continuous improvement!