Description

Description

- Maximum speed can reach 1000 rpm

- When stirring, it is necessary to de-ice the solder paste beforehand;

- Do not have to open the container;

- Power single phase 220v:

- No gas problem:

- Does not destroy the shape of tin powder:

- Fixtures are suitable for all kinds of 500g packaging solder paste cans;

- Mixing time can be set arbitrarily;

- Has manual speed control function

Machine main parameter

|

Item |

Solder paste mixer |

|

Dimension |

400x400x420mm |

|

Weight |

About 35KG |

|

Operating Voltage |

AC 220V 50Hz 60Hz >60W |

|

Operating speed |

Motor 1350 RPM revolution: 1000RPM Rotation: 500PRM |

|

Working capacity |

500 g. Syringe, red plastic tube, etc. the fixture can be customized. |

|

Stir two cans of solder paste at the same time |

500g |

|

Stiring time |

1-99 minute digitally adjustable |

|

Operation method |

Light touch button for easy operation |

|

Fixture function |

Universal fixture for all kinds of brand solder paste cans |

|

Running noise |

Low running noise <20dB |

Certificates

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA, etc.

Market

Our products had exported to more than 20 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:

SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

Packages

Step 1: Wrap with stretch film to prevent the equipment from.

Step 2: Vacuum paper packaging and moisture-proof bag, so that the machine can be kept dry during transportation to prevent moisture.

Step 3: Use straps and triangular wood to fix the machine to prevent damage to the machine during transportation.

Step 4: Each exported machine will be equipped with sturdy export wooden boxes, to ensure that the delivered product is good.

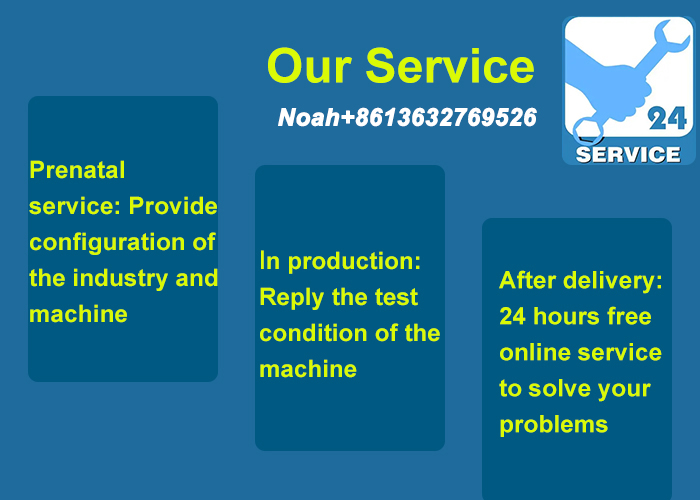

Service

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

FAQ

Q.How long can the delivery date take?

A.If have stock the delivery date is about 20 days, others is according to the actual situation.

Q.What is your usual payment term?

A.Our usual payment term is T/T, that requires to pay 30% in advance, and pay the balance off before the delivery of the goods.

Q.How long is the machine maintenance period, whether it is free?

A.The maintenance period of our machine is 1 year and its free for our clients, after the maintenance period we will arrange our engineers to check and test the machine one or two times a year freely.

Q.What services can you provide?

A.

- We provide whole line solution for our clients;

- We have local engineers in India, Egypt, Turkey. As long as you buy the machine, we will arrange engineers to install, debug and training you for free, until you learned how to operate the machine, our service is very convenient;

- We also have Chinese engineers which provide online services to operate the machine to solve the problems with the machine;

- We will visit our clients for twice a year to operate the machine and view the status of the machine;

- Our clients enjoy a free up grade of the machine.