- Standard SMEMA link port.able to connect with most market smt machine.

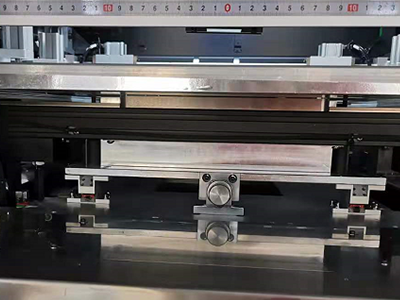

- NC slide way adjustment for conveyor width and speed.

- SMEMA interface, able to connect with most market smt machine.

- Dry-type, wet-type and vacuum-type with arbitrary combination for stencil cleaning system.

- ETON self development Vision alignment system.

- Built-in software diagnosis system.

- Standard stainless steel squeegee, unique design to improve the lifespan of squeegee blade.

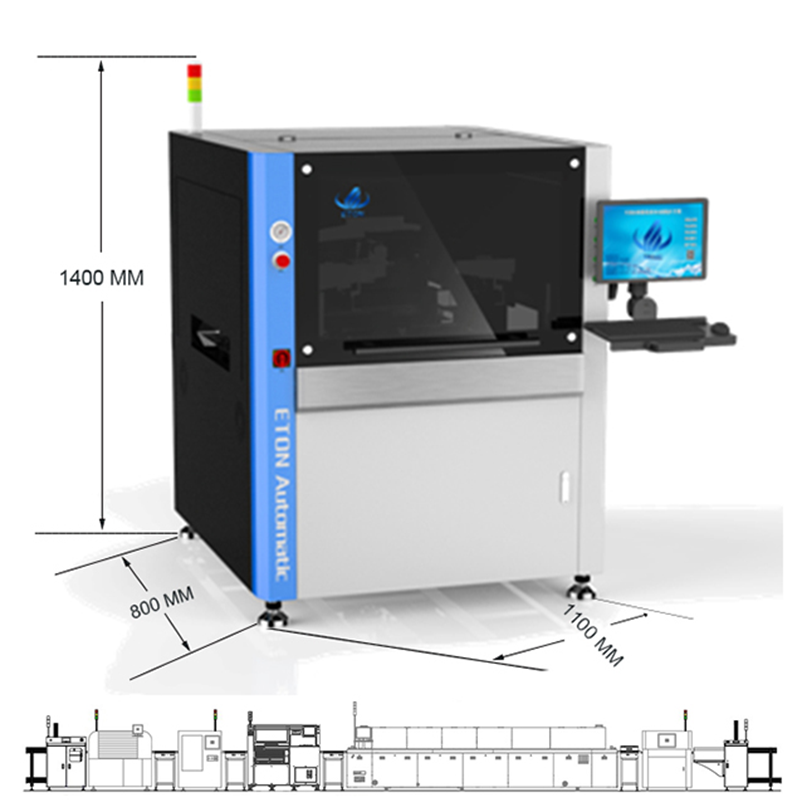

ET 4035 Automatic smt solder stencil printer General Description

Description

|

Model |

ET-4035 |

|

Dimension(MM) |

1100(L)* 800(W)* 1400(H) |

|

Mass/weight |

600KG |

|

Board Dimension |

Max:400*340mm Min:50*50mm |

|

Screen frames |

Max:737mm Min:420mm, thickness: 25-45mm |

|

PCB Warpage |

Max.FPCB diagonal 1% |

|

Squeegee pressure |

0-10kg/cm2 |

|

Squeegee speed |

6-300mm/sec |

|

Squeegee angle |

550 (standard) |

|

Squeegee angle |

Stainless steel standard, rubber squeegee |

|

Repeat position accuracy |

0.01mm |

|

Printing accuracy |

±0.025mm |

|

Cycle time |

≤9s(excluding printing and clean) |

|

Power input |

AC:22010%, 50/60HZ, 3KW |

|

FPCB transport over plate height |

20mm |

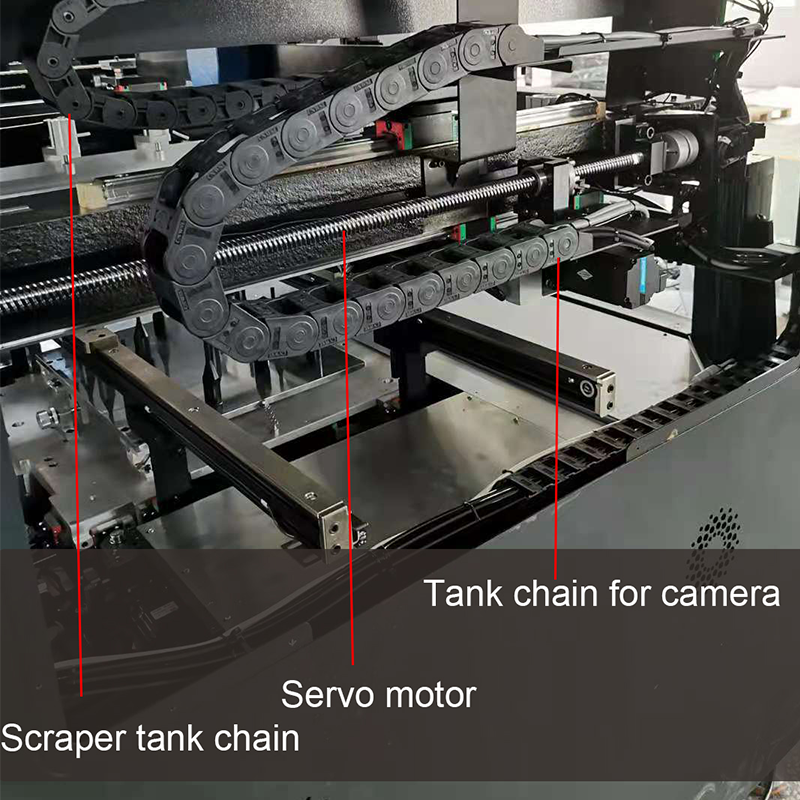

Suspended print head with programmable pressure automatic adjustment system

- Programmable pressure automatic adjustment system supports visible pressure values of front and rear squeegees and ensures accurate pressure control.

- Pressures of front and rear squeegees are separately adjusted, to compensate for pressure imbalance caused by fatigue deformation of the squeegee to prevent different printing quality in front and rear.

PCB clamping and support system

- Magnetic pins;

- PCB flexible side clamping system to ensure no bending and deformation during PCB clamping

- Elastic Z-direction pressing tablets (optional)

- Flexible automatic pins(optional)

Automatic clean system

Dry-type, wet-type, and vacuum-type with arbitrary combination for stencil cleaning system.

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.