YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

Technical parameter

|

Dimension |

|

|

Length |

2700mm |

|

Width |

2300mm |

|

Height |

1550mm |

|

Total Weight |

1700kg |

|

PCB |

|

|

PCB Length Width |

Max:1200*330mm Min:100*100mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Adjustable pressure pneumatic |

|

Mounting Mode |

Group picking and separately placing |

|

O.S. |

|

|

System |

Windows7 |

|

Software |

R&D independently |

|

Display |

Touch screen monitor |

|

Input Device |

Keyboard, Mouse |

|

Vision System |

|

|

No. of Camera |

5 sets ( Digital camera) |

|

Vision alignment, MARK correction |

|

|

Repeat Mounting Precision |

±0.02mm(Repeat precision) |

|

Mounting Height |

≦5mm |

|

Mounting Speed |

150000~180000 CPH |

|

Components |

LED 3014/ 3020/ 3528/ 5050 and capacitors, resistors, bridge rectifiers, etc. |

|

Components Space |

0.5mm |

|

Power |

380AC 50 HZ |

|

Power Consumption |

6kw |

|

Operating Environment |

23℃±3℃ |

|

Conveyor Transmission |

Max Length :1200 mm |

|

Transmission Speed |

>500mm/sec |

|

Transmission Direction |

Single(left→ right or right→ left) |

|

Transmission Mode |

Online drive |

|

Positioning way |

Optical |

|

Air supply |

0.4-0.6mpa (4-6kgf/cm²) 150N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 1 set |

Independent research and development by ETON |

|

X,Y,Z Axis Drive way |

High-end magnetic linear motor+ Servo motor |

|

Feeding System |

|

|

No. of Feeders Station |

68 PCS |

|

No. of head |

34 PCS |

|

Feeding way |

Electric feeder with double motor |

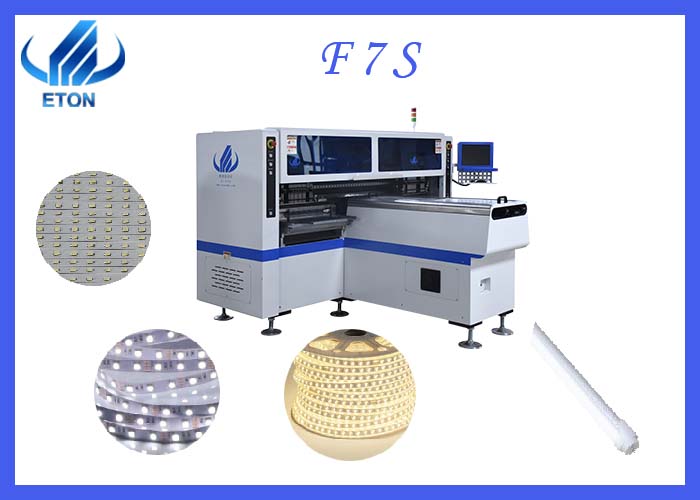

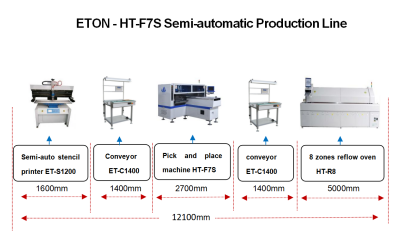

F7s introduction

Ht-F7s is a high-speed dual arm special placement machine, which is the best of high-speed machines. The placement of 2-4 kinds of materials at the same time does not affect the high production capacity. It is suitable for 0.6, 0.9, 1.2 meter hard light plate and half meter one meter soft light belt. Special for both arms. The mounting head is divided into left and right groups, with 17 suction nozzles in each group, a total of 34. 68 Feida. The lamp tube and lamp belt described above are specially pasted. High speed: the optimal production capacity per hour is 180000 CPH. It has its own correction function and can be pasted with RGB. It has an exclusive patented technology: group taking and separately placing.

SERVICE

Professional solutions: Provide professional SMT Full line solutions

Free Warranty: One-year warranty factory service.

Free Installation: On-site free installation to ensure smooth production.

Free Technical Training: Professional training of operating and maintenance.

Free Technical Support: 7 * 24 technical online support.

Free Software Upgrade: Offer free software upgrade whole lifetime

SMT LINE

FAQ

Q:What is the delivery date?

We will deliver the goods after 30 days’ deposit.

Q:Is electrical control developed independently?

Yes, the electrical control is by ourselves and have exclusive patent technology.

Q:Are you a manufacturer or trading company?

manufacturer. We have our own industrial park