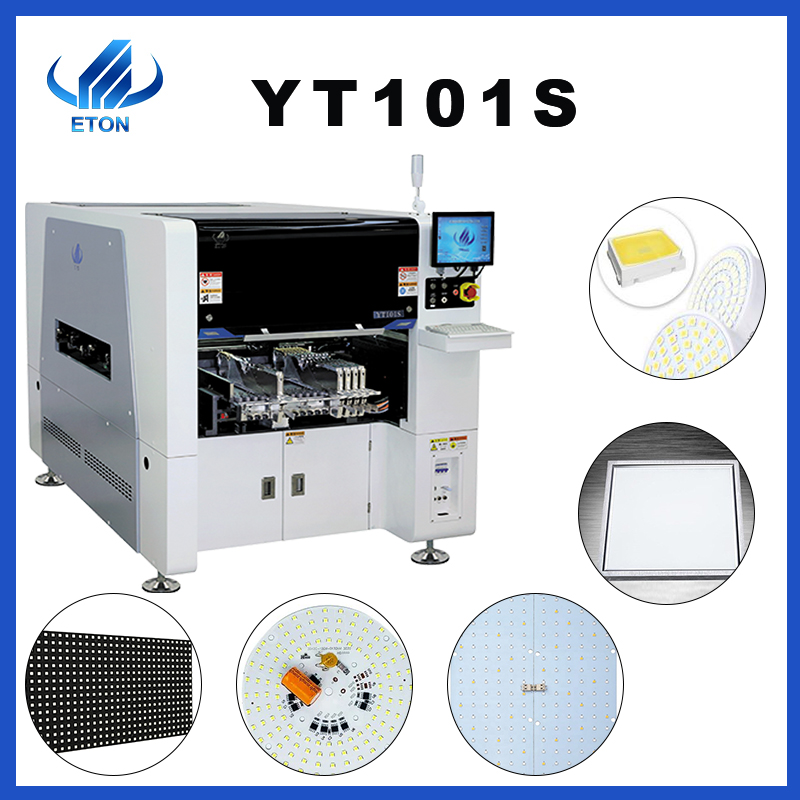

Description

Machine features:

1.Brand new self-developed high-precision placement head

2.High-speed precision head flight vision camera capture the image of placement accordingly.improve the speed and accuracy of placement 3

3.10 heads,The placement head adopt independent vacuum detection,improve placement performance the optimum speed reached 40000cph.

4.Components:Apply to 0201~40*40mm tape reel package.

Improve recognition performance, size up to 40*40mm, apply to BGA or CSP etc

5.Off-line programming.save time of changeover cycle • Software Al intelligent learning function and automatic optimization function.

6.Feeder system:Intelligent electric feeder.

Machine parameter:

|

Model |

YT101S |

|

Dimension(L*W*H) |

2154*1376*1762mm |

|

Weight |

1700kg |

|

PCB length width |

Max size:500*350mm |

|

PCB thickness |

0.5~4.5mm |

|

Repeat precision |

±0.02mm |

|

Mounting height |

≤20mm |

|

No.of camera |

2PCS |

|

Vision alignment, Mark correction |

|

|

Components range |

Min 0201~40*40MM Packages and IC etc |

|

Rail |

Rail 1 is fixed |

|

Power consumption |

380AC50HZ 4KW |

|

Optimum Mounting speed |

40000CPH |

|

No. Of feeders station |

16 PCS ,tape reel packages 32 PCS |

|

No. Of head |

10 PCS |

|

Feeding way |

Intelligent double head feeder. |

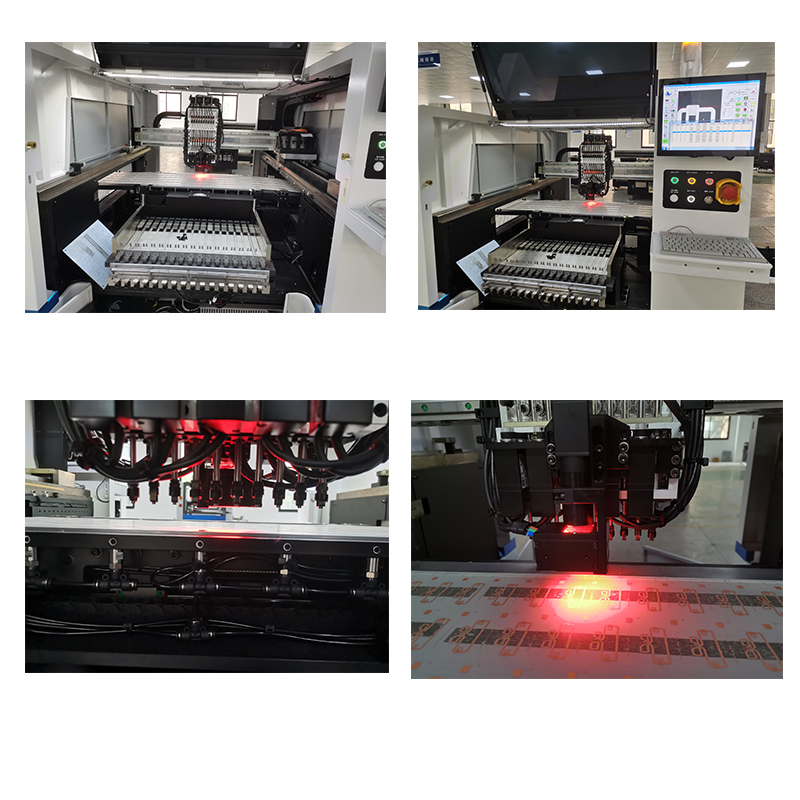

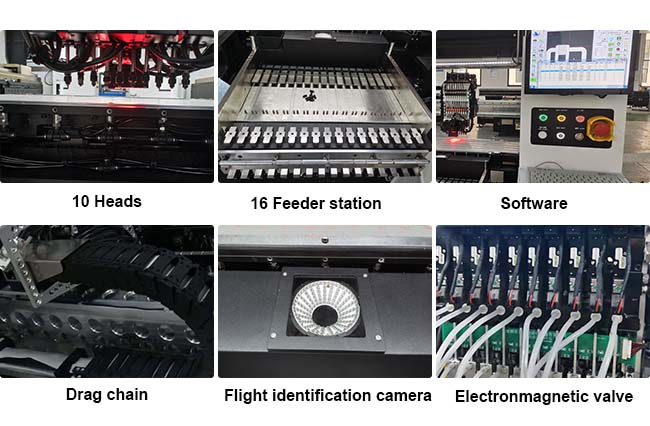

Machine main part:

- Mounting heads:After the nozzles is installed, take the material,mounting the components.

- The feeder station: is used to place the feeder.

- Software:The software is the brain control of the machine, the operation of the machine can program the placement program.

- Drag chain:Wrap the wire to ensure the translation of the wire, reduce wear and prolong the service life.

- Flight identification camera:Take a photo of the components picked up by the head, compare the placement program done with the Mark camera before, and calculate whether it is necessary to compensate for the positive components.

- Electron magnetic valve:The solenoid valve of the placement machine can be matched with different circuits to achieve the desired control, and the accuracy and flexibility of the control can be guaranteed.

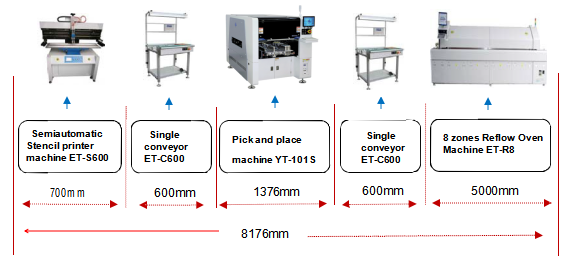

SMT production line:

As a large company,Our enterprise has more than 20 years of experience in SMT machines field, we can provide you with complete line solutions.

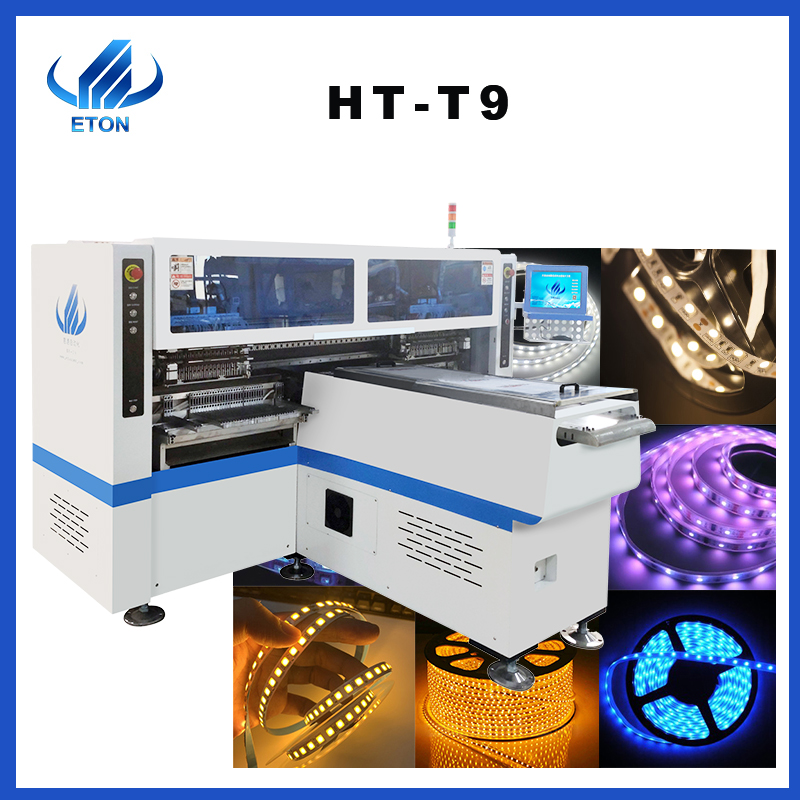

Application:

This machine can be applied to components as small as 0201 and as large as 40mm, and can also mount BGA, CSP and other ball grid arrays.

The finished product is not only LED lights(like led bulb,down light,circuit board, power driver etc) but also more complex PCBA boards, such as more accurate display P2.5,P3.91 etc.

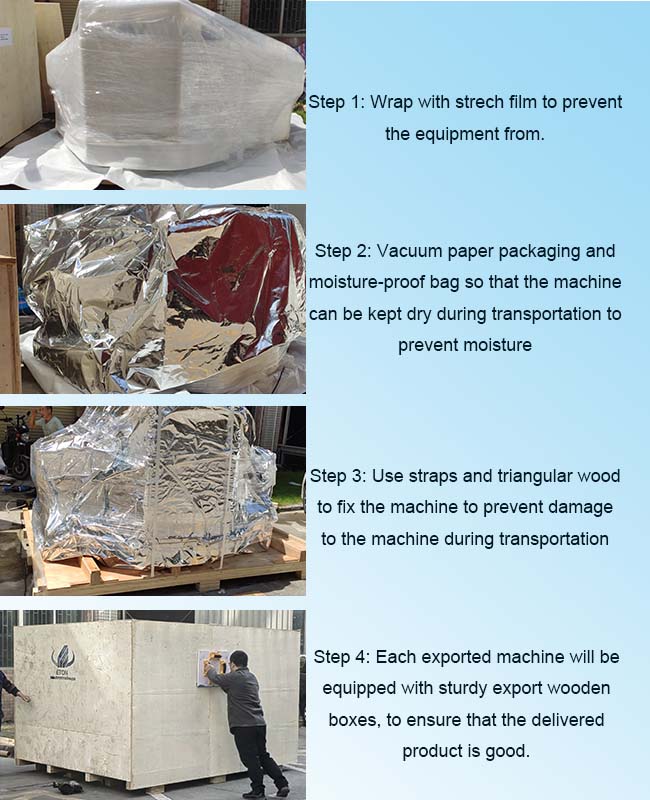

Packing:

Packing: standard is plastic film wrap the LED SMT machine, then load into one 20″ container; Wooden box packing can be customized.

Delivery: 35-40 days after 30% T/T prepayment, buyer should come to inspect when we do test running, after testing, pay the 70% balance before delivery.

FAQ:

1.How to ensure the quality of the machine?

We have our own industrial park. There are production centre and R&D centre and quality inspection centre to guarantee the machines quality. Before shipping, we will test the machine again to make sure the quality of the machine is good.

2.What is the feeder station and software system of the machine?

Our feeder is electric feeder, can satisfy the requirement of different SMD LED components.

Programming software using database system, different types of PCB programming can be stored, convenient adjust, new product only need one time programming, can use at any time in the future.

3.Why choose our pick and place machine?

First.Decades development history.

Second .80% large and listed Led factory are our client.

Third. Top 1 in high speed pick and place machine in China.

Fourth. Optimum After-sales service system.