- The direction of entering the plate can be selected arbitrarily and can be combined freely

- Inner tooth transport belt with special process to prevent jamming

- Programmable transportation speed control makes the stop more accurate

- Flexible clamp is adopted to ensure that the PCB size is flat and the contact net is fully clamped between the PCB and the side. 4. The flexible clamp is adopted to ensure the effective switching between the PCB and the side

- The optimized module driving structure can effectively improve the stability of platform adjustment and realize ultra-fine transmission under micro adjustment. It is a printing machine that meets the requirements of higher precision. The utility model has the advantages of simple and reliable structure and convenient adjustment, and can quickly realize different thicknesses

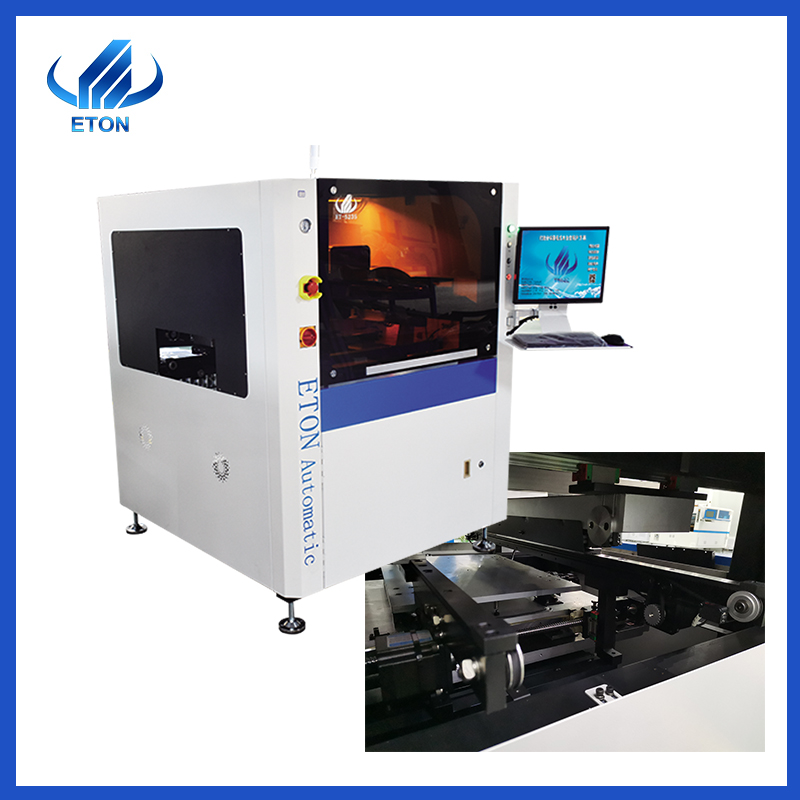

Full Automatic Stencil Printer Machine

Description

Technical parameter

|

Model |

ET5235 |

|

|

Screen Frames |

Max Size |

737mm |

|

Min Size |

470mm |

|

|

Thickness |

25-40mm |

|

|

PCB size |

Max:520*350mm Min:50*50mm |

|

|

PCB thickness |

0.6-6mm |

|

|

PCB warpage |

<1%(Max PCB diagonal) |

|

|

Transport height |

900+-20mm |

|

|

Transport direction |

Left-Right;Right-Left;Left-Left;Right-Right |

|

|

Transport speed |

Max1200mm/s Programmable |

|

|

Board location |

Support system |

Magnetic Pin/Up-down table adjusted by manual |

|

Clamping system |

Unique top flattened;side clamping |

|

|

Print speed |

Two independent direct-connect motor-driven printheads |

|

|

Squeegee speed |

6-300mm/sec |

|

|

Cycle time |

<=9s |

|

|

Product changeover |

<5Min |

|

|

Air required |

4.5-6kg/cm |

|

|

Control method |

PC control |

|

|

Dimension |

1240(L)*1450(W)*1650(H)mm |

|

|

Weight |

Approx:700kg |

|

|

PCB transfer overhead height |

10mm |

|

Full Automatic Stencil Printer Machine

Features

PCB transportation and positioning system

- The direction of entering the plate can be selected arbitrarily and can be combined freely

- Inner tooth transport belt with special process to prevent jamming

- Programmable transportation speed control makes the stop more accurate

- Flexible clamp is adopted to ensure that the PCB size is flat and the contact net is fully clamped between the PCB and the side. 4. The flexible clamp is adopted to ensure the effective switching between the PCB and the side

- The optimized module driving structure can effectively improve the stability of platform adjustment and realize ultra-fine transmission under micro adjustment. It is a printing machine that meets the requirements of higher precision. The utility model has the advantages of simple and reliable structure and convenient adjustment, and can quickly realize different thicknesses

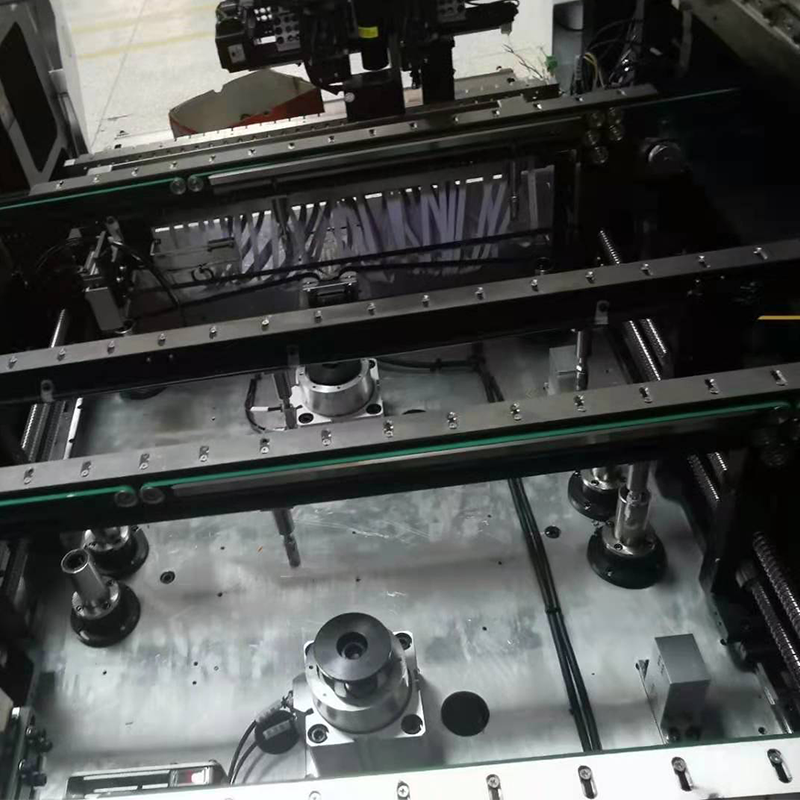

Steel mesh positioning system

- Arch bridge type suspended direct scraper

- Large and small steel nets are universal, with good and wide applicability

- Sectional fixed steel mesh frame

Company profile

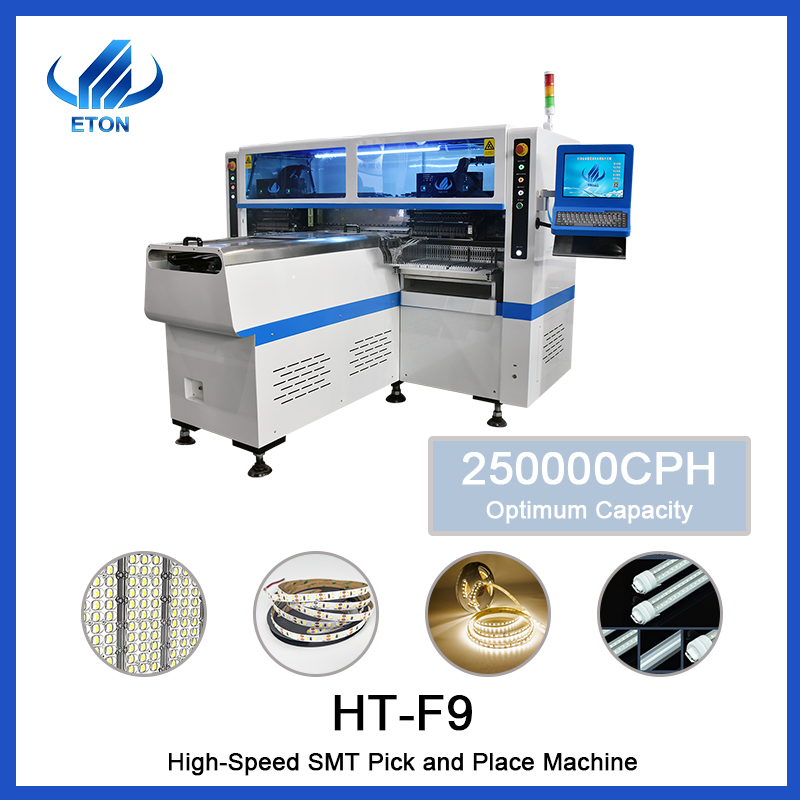

ETON is not only in the leading position in the field of photoelectric high-speed mounter, but also has made a breakthrough in the field of SMT high-speed mounter. It has successfully developed a number of high-cost SMT high-speed universal mounter. Its products are widely used in lighting, display screen, electronics, driving power supply, household appliances, new energy and other industries.

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.