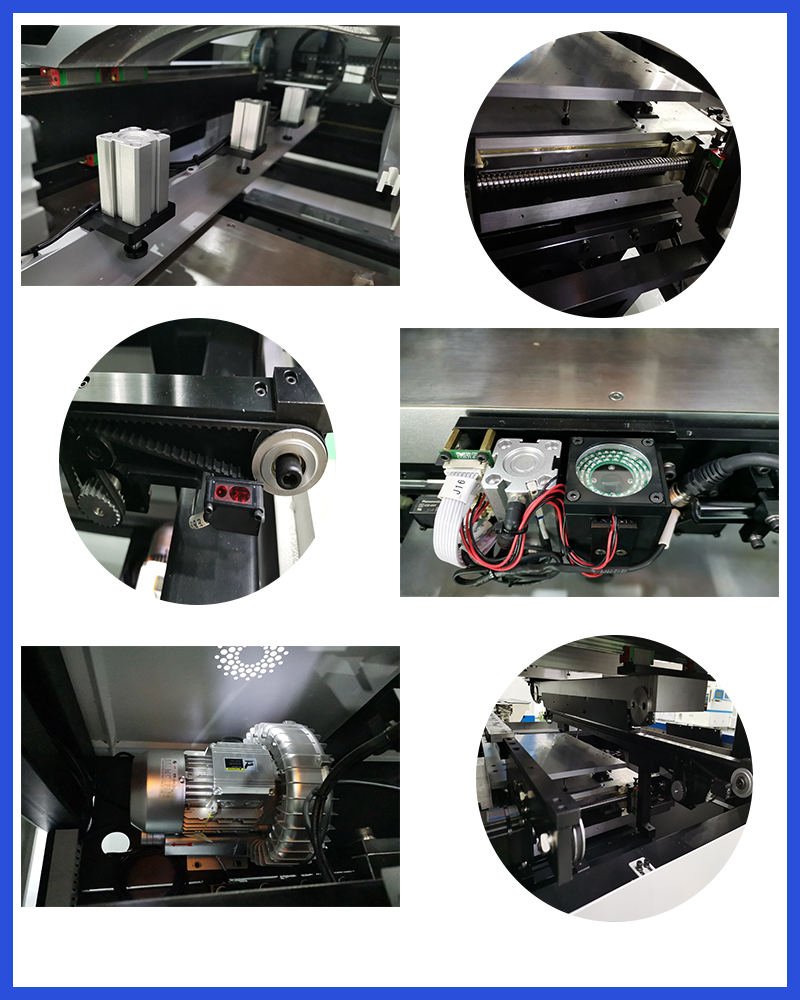

The optimally designed module drive structure effectively improves the stability of the platform calibration and realizes ultra-small transmission under fine-tuning, so that the machine can meet the printing requirements of higher precision. The structure is simple and reliable, the adjustment is convenient,and the height adjustment of the support PIN of the PCB board with different thickness can be quickly realized.

Full automatic stencil printer machine

Description

|

Model |

ET5235 |

| Screen Frame max size | 737mm |

| PCB size | max 520*350mm |

|

Squeegee pressure |

0~10kg/c㎡ |

|

Squeegee accuracy |

0.025mm |

|

Squeegee type |

Steel scraper,PV scraper |

|

Stencil separation speed |

0.1~20mm/sec programmable |

|

Cleaning system |

Dry, Wet, Vacuum(programmable) |

| Control method | PC control |

the PCB loading direction can be selected and combined freely

2.adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh

3.The size of steel mesh is universal,with good and wide applicability

4. The fully closed-loop scraper pressure feedback device monitor the scraper pressure at all times, making the printing more full

5.X,Y axis adopts high-precision grinding ball screw, driven by servo motors at both side

6.The polarizer is added inside, and the MARK of different shapes is automatically and accurately grasped, and the upper, lower and coaxial three-way uniform light sources.

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

Q: Why do you choose our product?

- our product quality is guaranteed, and we have overseas local engineers, can arrange door to door installation.

- Software lifetime free upgrade

- Free installation and training

Provide 1-2 times a year free for machine repair, after the warranty period.

Q: About technical offer

A: As for machine operation, we will arrange engineers to go to your factory for installation and teaching after you buy our machines.

If you have engineers who have been involved in the installation of SMT equipment, we can teach you how to install it online.