PCB Transport and Clamping system:the PCB loading direction can be selected and combined freely,unique crafted internal gear conveyor belt to prevent jamming, adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh

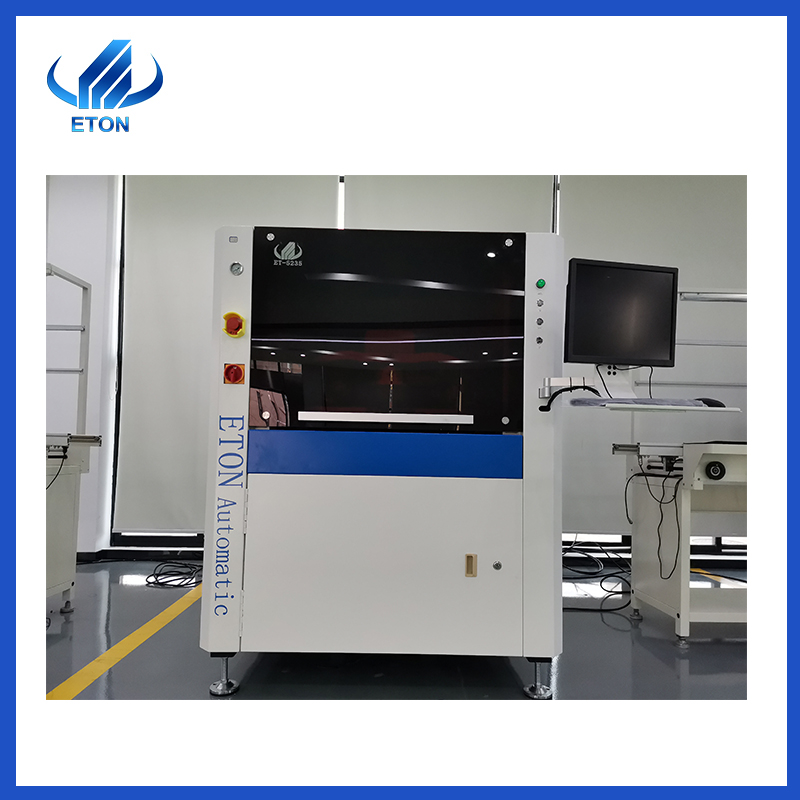

Full automatic vision stencil printer machine

Description

Machine parameter

|

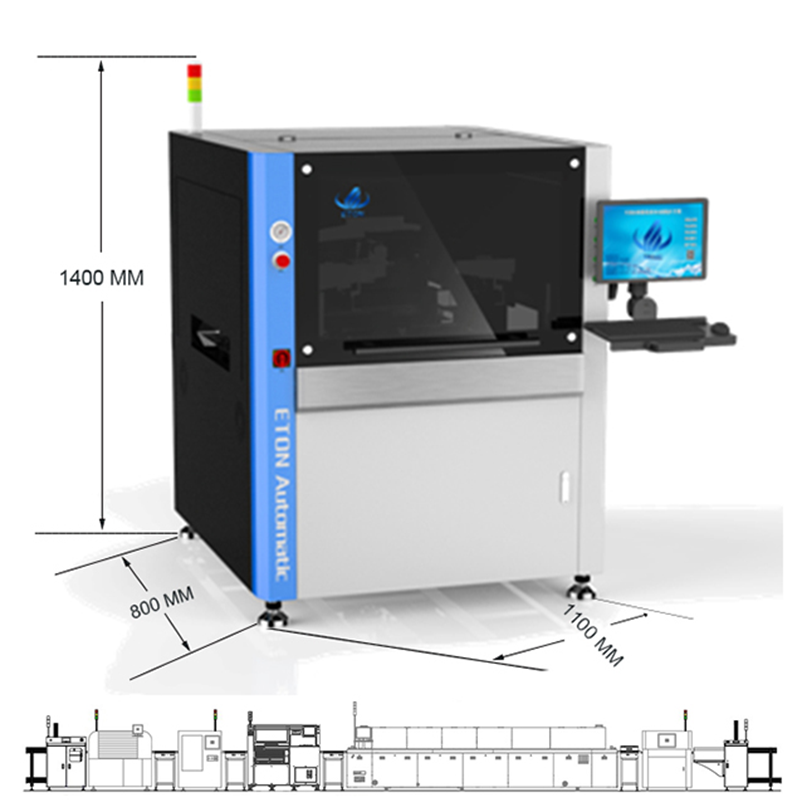

Model |

ET5235 |

|

Printer head |

Two independent direct-connect motor-driven printheads |

|

Squeegee speed |

6~300mm/sec |

|

Squeegee pressure |

0~10kg/c㎡ |

|

Squeegee angle |

55º |

|

Squeegee type |

Steel scraper,PV scraper |

|

Stencil separation speed |

0.1~20mm/sec programmable |

|

Cleaning system |

Dry, Wet, Vacuum(programmable) |

|

Table adjustable ranges |

X:±5mm Y:±5mm |

Machine feature

PCB Transport and Clamping system:the PCB loading direction can be selected and combined freely,unique crafted internal gear conveyor belt to prevent jamming, adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh

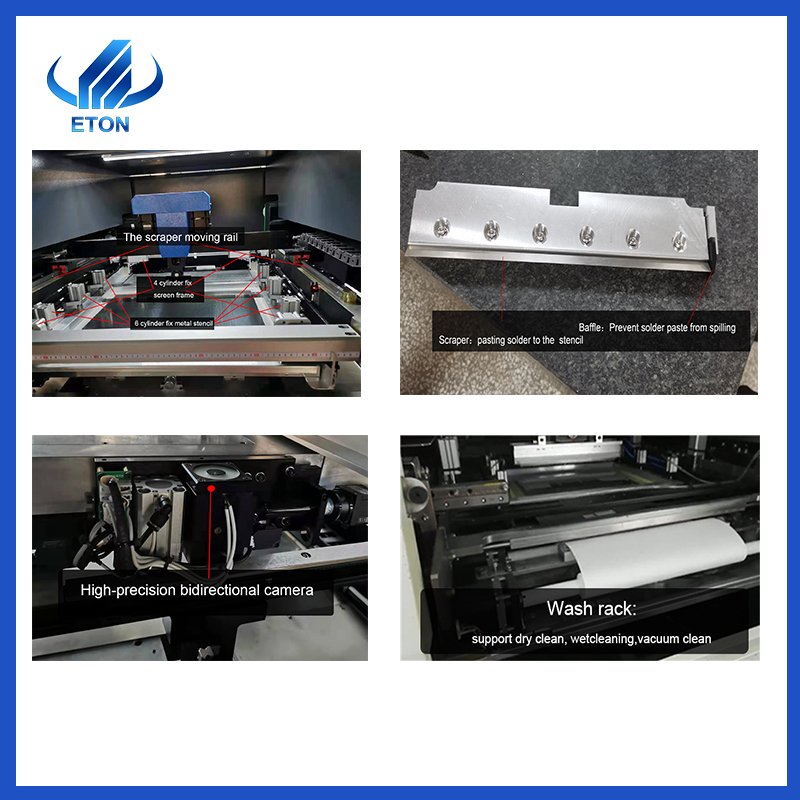

Scraper system: cast aluminum scarper beam to ensure smoother running of scarper, programmable suspension self-adjusting stepper motor drives print head,embedded scale, never fall of.

Operation interface: easy to learn and easy to use friendly operation interface, make program files with teaching and navigation functions, with prompts for each step,one key switch between Chinese and English,with operation log, fault record analysis and diagnosis and other functions

Image and optical system:X,Y axis adopts high-precision grinding ball screw, driven by servo motors at both side

Package

We have to pack in vacuum wooden cases to ensure the safety of the goods in the transportation process. Our packaging process is in the charge of professionals, and foreign trade salesmen track the delivery throughout the process

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.

FAQ

Q:Why choose us?

A: We provide professional in SMT line for 11 years,with strong production and strong capacity and R&D team,Has provided a lot of clients with modern SMT production line solutions.

Q: What about the shipping methods?

A: A variety of transportation methods for you to choose. By sea, air and road.

Q: Do you have service office in India?

A: Yes, we have service office in Deli and Mumbai,and we have three India local engineers can support quickly.

Q: What is the mounting modeof your SMT machine?

A: Our multifunctional pick and place machine can group picking and separately placing or separately picking and separately placing, high-speed pick and place machine can group picking and group placing.