The optimally designed module drive structure effectively improves the stability of the platform calibration and realizes ultra-small transmission under fine-tuning, so that the machine can meet the printing requirements of higher precision. The structure is simple and reliable, the adjustment is convenient,and the height adjustment of the support PIN of the PCB board with different thickness can be quickly realized.

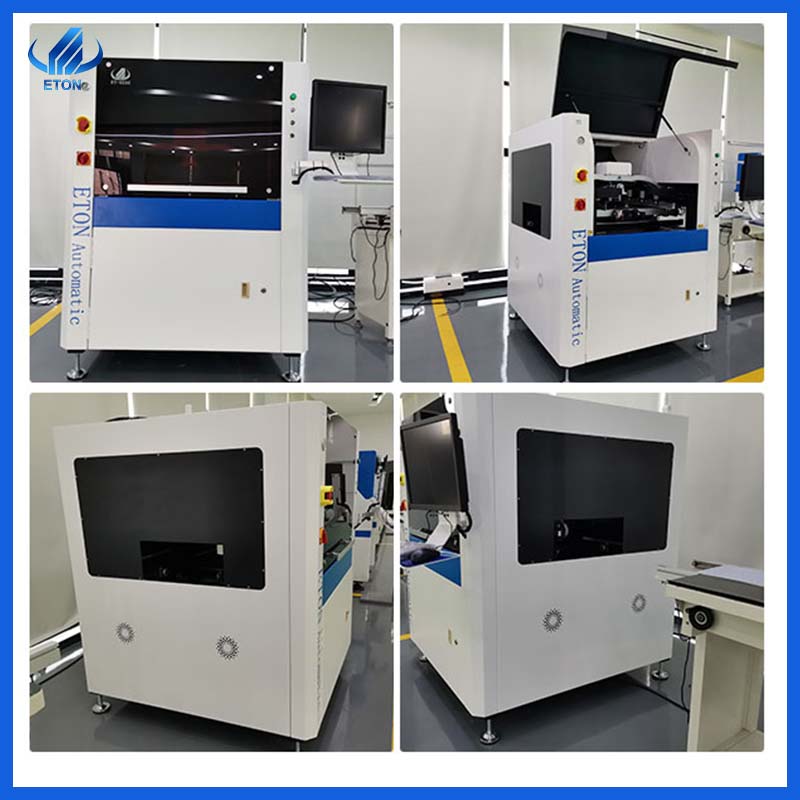

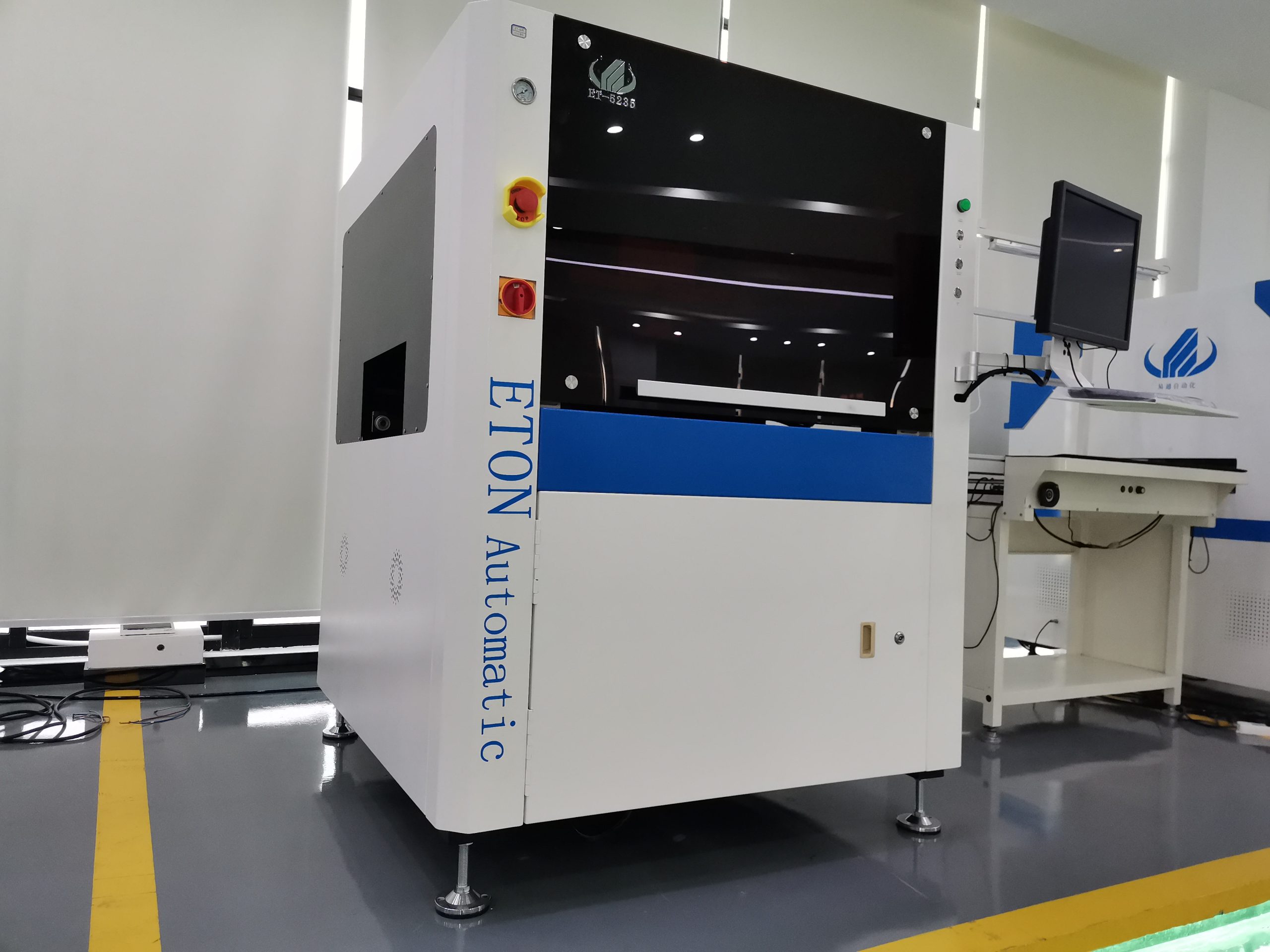

Full automatic vision stencil printer machine

Description

Machine features

The optimally designed module drive structure effectively improves the stability of the platform calibration and realizes ultra-small transmission under fine-tuning, so that the machine can meet the printing requirements of higher precision. The structure is simple and reliable, the adjustment is convenient,and the height adjustment of the support PIN of the PCB board with different thickness can be quickly realized.

The fully closed-loop scarper system,improve operation stability and prolong lifetime

With good human-machine dialogue function

The polarizer is added inside, and the Mark of different shaped is automatically and accurately grasped, and the upper,lower and coaxial three-way uniform sources.

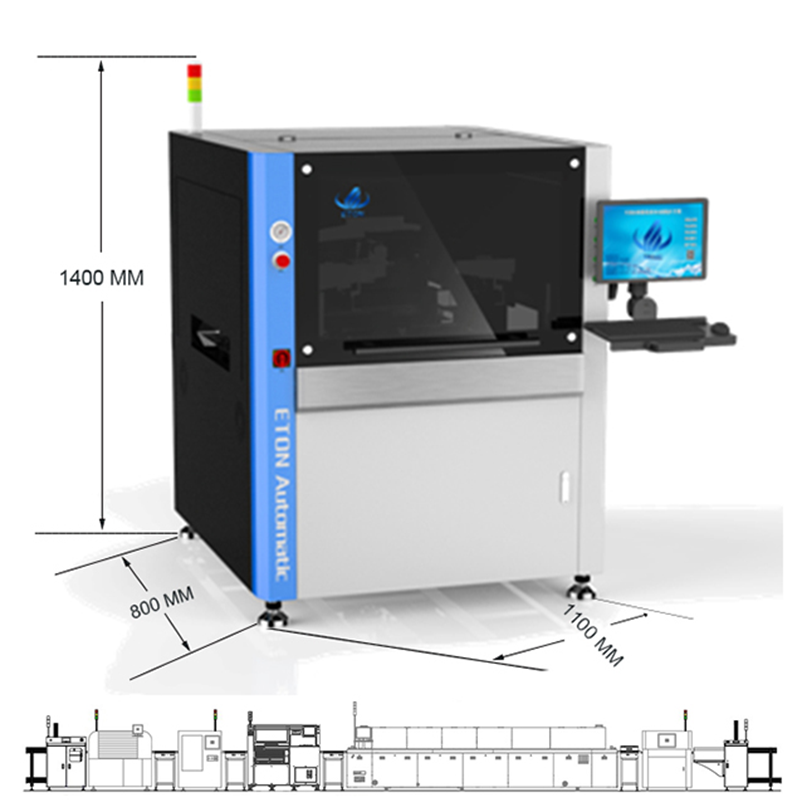

Machine parameter

|

Model |

ET5235 |

|

|

Screen Frames |

Max Size |

737mm |

|

Min Size |

470mm |

|

|

Thickness |

25~40mm |

|

|

PCB Size |

Max:520*350mm;Min:50*50mm |

|

|

PCB thickness |

0.1~0.6mm |

|

|

PCB warpage |

<1%(Max PCB diagonal) |

|

|

Transport height |

900±20mm |

|

|

Transport direction |

Max 1200mm/s Programmable |

|

|

PCB Board location |

Support system |

Magnetic Pin/Up-down table adjusted by manual |

|

Clamping system |

Unique top flattened ,side clamping |

|

|

Print head |

Two independent direct- connect motor- drive print heads |

|

|

Squeegee speed |

6~300mm/sec |

|

|

Squeegee pressure |

0~10kg/cm2 |

|

|

Squeegee type |

Steel scraper(Standard), PV scraper(Option) |

|

|

Stencil separation speed |

0.1~20mm/sec Programmable |

|

|

Cleaning system |

Dry,Wet,Vacuum(Programmable) |

|

|

Printing accuracy |

±0.025mm |

|

|

Cycle time |

≤9s(Exclude printing&cleaning) |

|

|

Product changeover |

<5Min |

|

|

Control method |

PC control |

|

|

Dimension |

1240(L)*1450(W)*1650(H)mm |

|

|

Weight |

Approx: 700kg |

|

|

PCB transfer overhead height |

10mm |

|

|

Air required |

4.5~6kg/cm2 |

|

Our advantages

1.We have our own industrial park to produce and manufacture machines, at the same time, we are equipped with all strong R&D teams, focusing on the research and development of SMT machines and equipment

2.We occupy 80% of the LED light customers in the market, and at the same time, our products have been widely recognized and approved by customers

3.We have engineers and offices abroad, and can provide machine installation and on-site service and training free of charge

4.The software of our machine is independently developed and can provide free upgrades for life. Some hardware of our machine is made of well-known brands at home and abroad to ensure the quality of the machine

Our clients

Our products have been exported to more than 20 countries and regions. We have also helped many customers at home and abroad establish production plants, which have been highly praised and affirmed by many customers

Related SMT Machine

We are not only a top chip mounter manufacturer, but also a manufacturer of some peripheral equipment, not only can provide pick and place machine, but also can provide you with printing machine, glue dispenser, conveyor, transfer machine, reflow soldering machine, can Together with the placement machine to form a production line, improve the production efficiency of products.

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.

FAQ

1.Why should you buy from us not from other suppliers?

We are high-tech professional manufacturer of SMT machine with more than 10 years with good quality and reputation. We have rich experience in helping client to start new factory and new line. “Professional, high-effective, cost-saving” are our advantages.

2.Is your software interface in English?

English interface and Chinese interface are both available.

3.This is the first time I use this kind of machine, is it easy to operate?

Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.