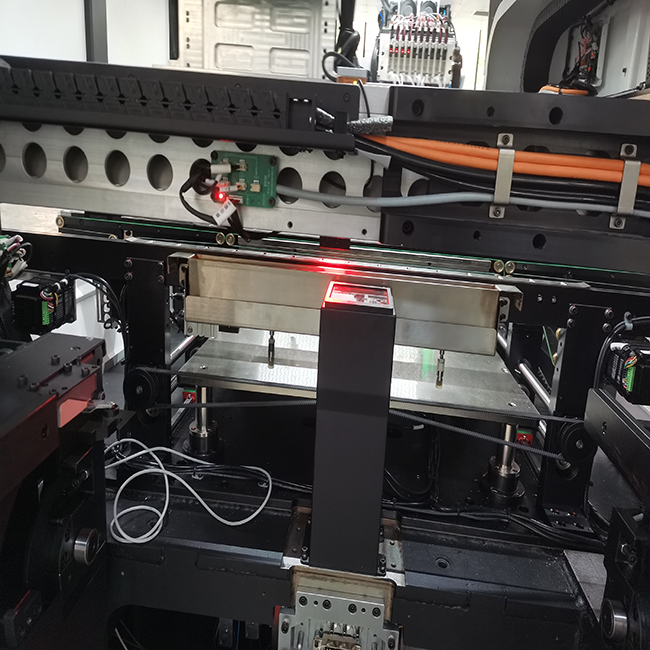

YT 202S is one of the newly launched YT series products from ETON. The dual-module placement machine can produce two identical PCB boards at the same time, improving production efficiency.Under optimal conditions, the production capacity can reach 80000CPH, and the precision is very high, and the minimum mounted components can reach 0201.

High precision led display making mounter

Description

High precision led display making mounter

Machine features

|

The ultimate host with three characteristics, a new fixed flight identification camera, with identification components corresponding to 40*40mm, can identify ball grid arrays such as BGA or GSP. |

|

Vacuum sensing device, each suction nozzle has an independent detection function, which improves the stability and reliability of the equipment. |

|

Support YT series universal double head intelligent feeder, and realize stable and accurate feeding by optically correcting the feeding position. |

|

Ultra high speed mounting capacity of products at the same level. |

|

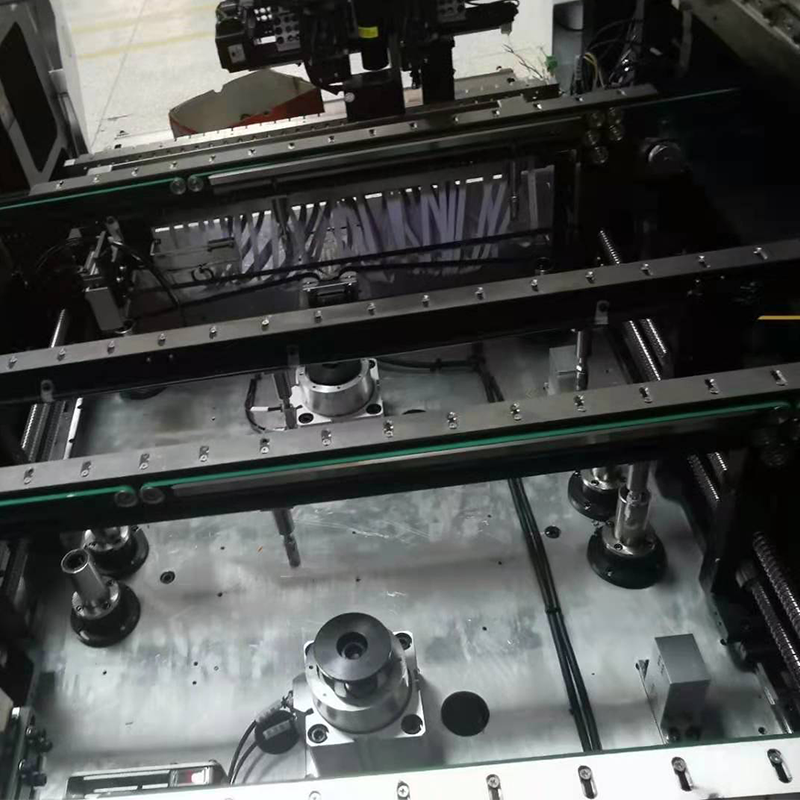

Feeding system: 1. The feeder is equipped with a special docking cart The double-sided station has 32PCS, which can load 64 trays of materials, and the single-sided station has 16PCS and can load 32 trays of materials. 2. Support multi-layer IC Tray feeder, realize easy completion of alternate work with docking cart. 3. Transport track system 4. Double arms and double heads, flexible PCB processing capability, double rail structure, can realize the production of a large PCB board.Modular placement head and various production modes, flexible assembly line. |

High precision led display making mounter

Machine main parameter

|

1.PCB |

|

Suitable for max PCB size is 500*450mm, mini size is 50*50mm PCB using cylinder clamping, track width adjustable for clamping The Rail 1 is fixed but other is flexible The PCB thickness is 0.5-4.5mm |

|

2.Camera |

|

The No.of camera is 4 sets digital camera, head flight vision recognition component, vision alignment, mark correction |

|

3.Precision |

|

The repeat precision is ±0.02mm, support for 0201-40*40 IC |

|

4.Component range |

|

Mini 0201-40*40mm package and IC, apply to BGA, CSP etc. Max mounting height is 20mm |

|

5.Mounting speed |

|

The optical speed is 80000 CPH with 20 mounting heads |

|

6.Feeding way |

|

Intelligent double head feeder |

SMT Production line

1.Solder paste printer Machine: The solder paste or patch glue is leaked onto the pads of the PCB board to prepare for the next step of soldering the components.

2.Conveyor : transmission the PCB board to pick and place machine, at the same time, It is used for connection between SMT production lines and can also be used for buffering of PCB boards

3.Pick and place machine YT202S: Accurately mount surface mount components to fixed positions on the PCB board.

4.Conveyor: transmission the PCB board to reflow oven, at the same time, It is used for connection between SMT production lines.

5.Reflow oven: Melt the solder paste or die glue to firmly bond the components to the driver board.

Our clients

Our products had exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

FAQ

Q: Is hard to use these machines?

A: No, not at all. All our machine are automatic, you just type in the program and it will work. The operation is relatively simple and I believed that certainly learn in two days.

Q: if there is a problem with the machine,can it be repaired?

Of course, the machine failure rate is 0.001 , and in addition to the warranty period, we also provide you with free maintenance 1-2 times a year.

Q: Why do you choose our product?

- our product quality is guaranteed, and we have overseas local engineers, can arrange door to door installation.

- Software lifetime free upgrade

- Free installation and training

- Provide 1-2 times a year free for machine repair, after the warranty period.

Contact us:

David Whatsapp/Wechat/Tel: +86 13827425982

E-mail:david@eton-mounter.com

.jpg)