Description

-

Dual arm magnetic linear high speed mounter for flexible strip(no wire), producing 4 types materials at the same time capacity reach 250000 CPH.

- Producing 4 types of materials at the same time with high capacity, available for 5m, 50m or any length of flexible strip and Roll to Roll.

- Dual arm four module, 17 nozzles for each mounting part, part A, part B can be mounted separately or synchronously.

- Calibration automatically, high precision, available for for RGB.

- Exclusive patent technology: Group to pick and group to mount.

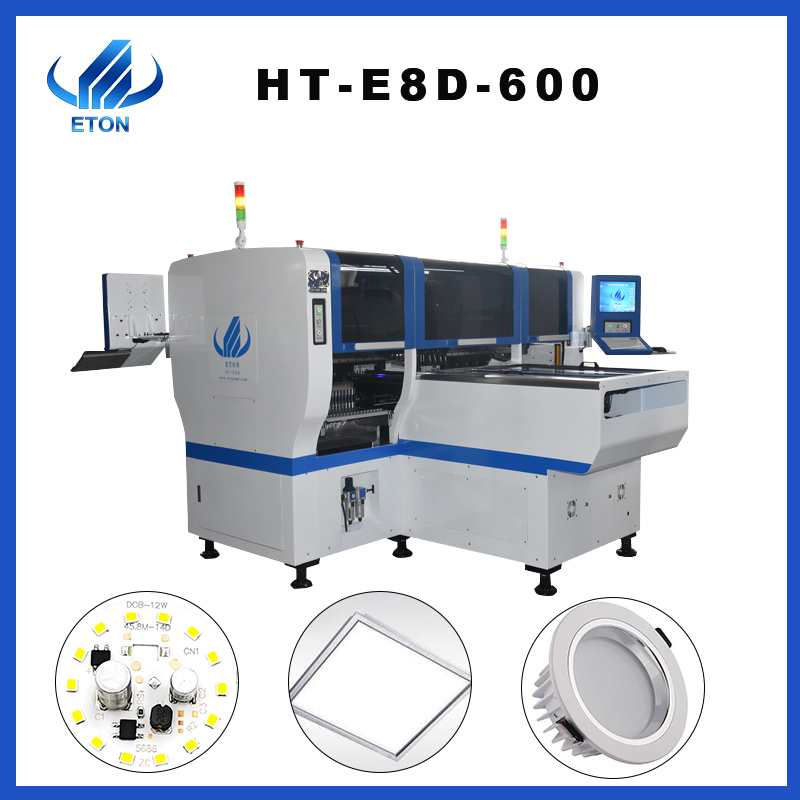

Model

HT-T9

Dimension

3100*2250*1650 mm

Total weight

1700 kg

PCB length width

250 mm*any length

PCB thickness

0.5-1.5 mm

Mounting precision

±0.02 mm

Mounting speed

20-25 W CPH

No. of head

68 PCS

As an experienced manufacturer in SMT line, provide a whole production line for our clients which is a convenient mission for the services of our company, we have a 50000 square meters industrial park, and there are production center and R&D center and quality inspection center to guarantee the machines quality.

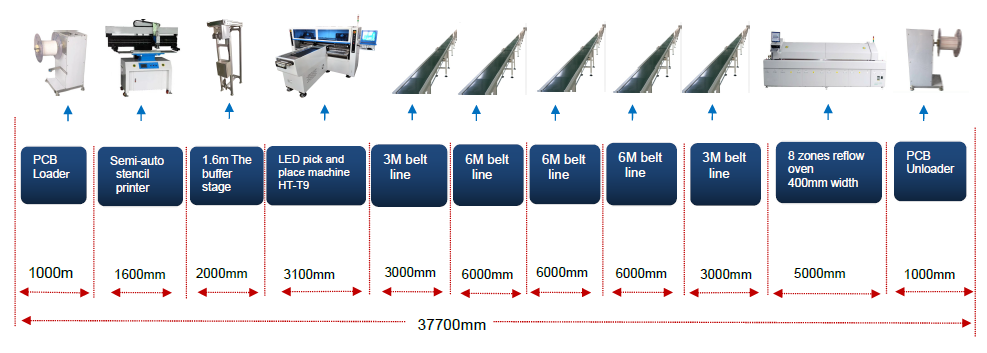

Here is the semi-automation line of the machine:

As for the 11 years trade with more than 20 countries with our SMT high speed pick and place machine, we have come into business with SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, SKYQUAD, NTL, KONARK, CEPL, FLARE, SLS , ACK, KENDAL, KING LED,RangDong, TAMKIM , UNISTAR, etc.

Our company has participated in various exhibitions in foreign countries, including India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, etc.

Q. What components is your machine mainly mounted?

A. For the multi-functional pick and place machine that can mount IC, LED chip, resistors, capacitors and shaped components like lens.

Q. How long can the delivery date take?

A.If have stock the delivery date is about 20 days, others is according to the actual situation.

Q.How can I make inspection when something wrong with the machine?

A. Well, the inspection is taken by our professional engineer to check and modulate the machine, if you counter any problem of our machine please contact us, and we will arrange our engineer to solve it.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com