Description

Machine main parameter

|

Dimension: 2700mm*2300mm*1550mm |

|

|

Total weight |

1700kg |

|

PCB Length width |

Max: 1200*330mm Min: 100*100mm |

|

PCB Thickness |

0.5-5mm |

|

PCB clamping |

Adjustable pressure pneumatic |

|

Transmission speed |

>500mm/sec |

|

Conveyor transmission |

Max length: 1200mm |

|

Repeating Mounting precision |

±0.02mm |

|

Component space |

0.5mm |

|

Component height |

≤5mm |

|

No. Of feeders station |

68PCS |

|

No. Of head |

68PCS |

|

Operating environment |

23℃±3℃ |

|

Power consumption |

6KW |

|

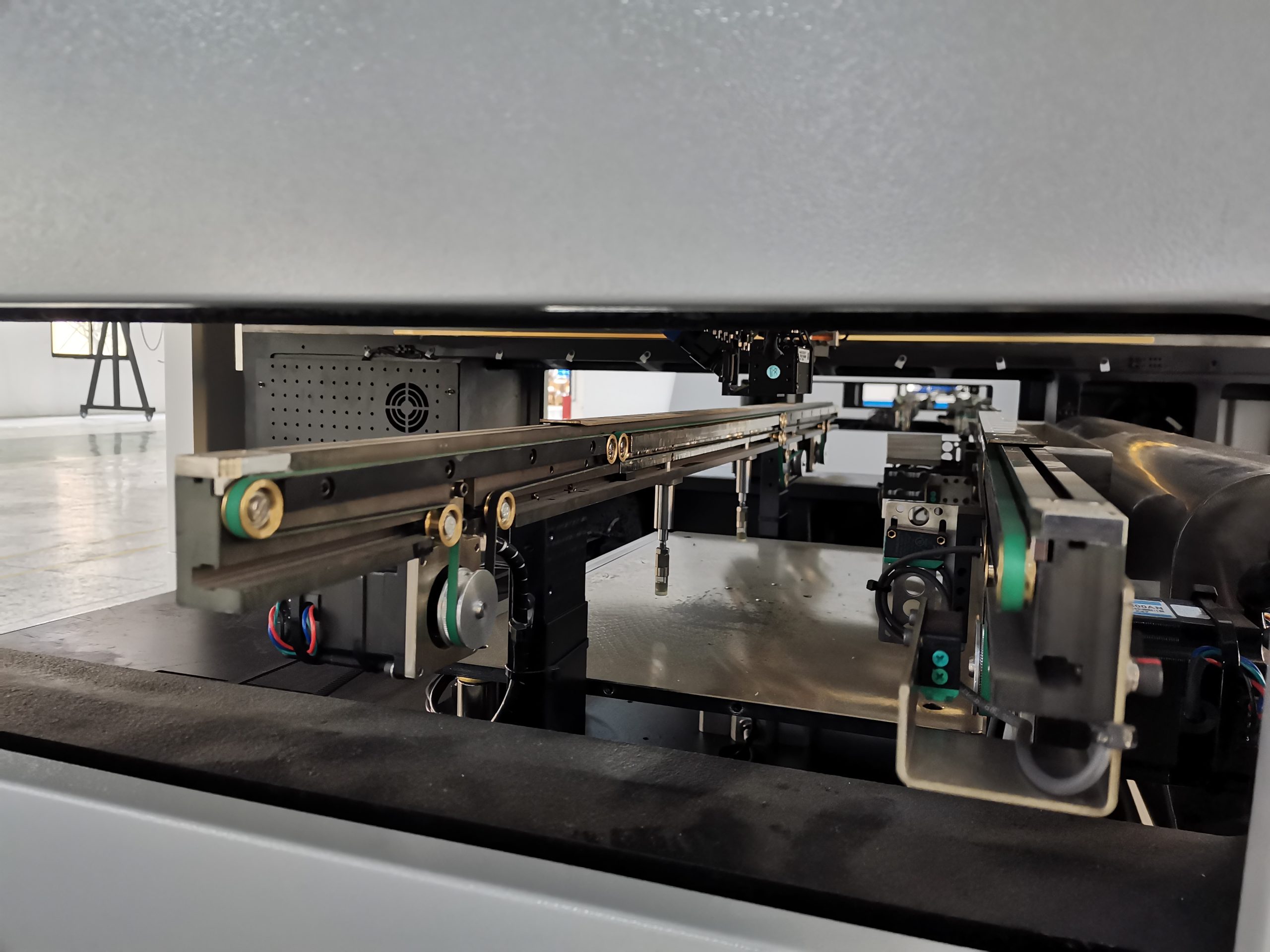

X, Y, Z Axis drive way |

linear motor and serve motor |

Machine main features and Machine main part

1. The HT-F9 is suitable for mounting and the PCB plate size is 1200*330mm to 100*100mm.

2. HT-F9 is suitable for products with fewer types of components and simple order of components

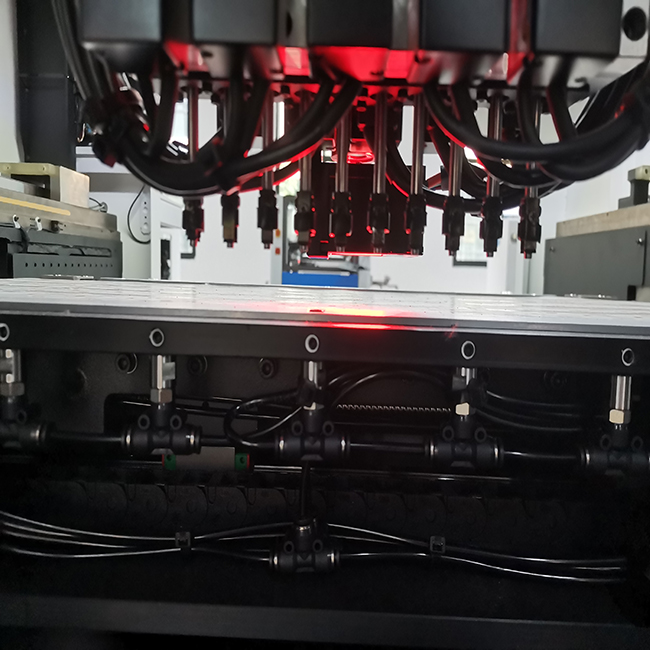

3. HT-F9 has five sets of camera, including: 2 nozzles adjustable camera which can to adjust the nozzle spacing by taking on the center of the nozzle;2 feeder adjustable camera adjusting the feeder by taking feeder station center line;1 MARK camera to Mount the PCB board by scanning MARK points.

4. HT-F9 has 68 PCS of nozzles and 68 PCS of feeders station so that the optimum capacity will be reached 250000 CPH.

5. HT-F9 has four modules and double arms which can produce four different types of materials at the same time.

6. This is his biggest highlight that the HT-F9 can keep high speed and high precision when the mounting mode is group to pick and group to place.

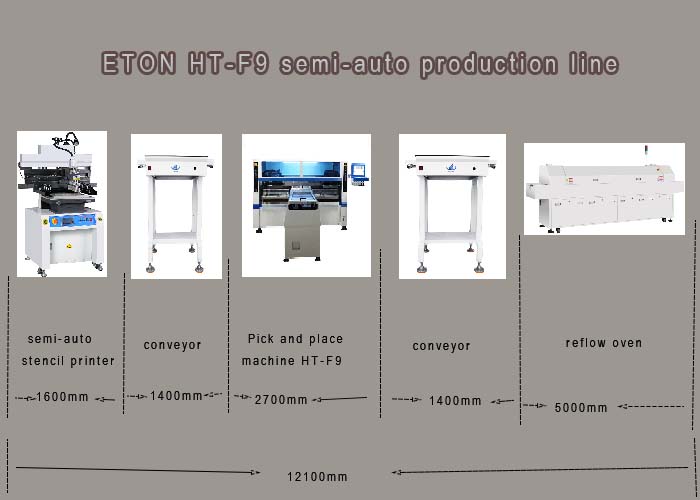

SMT Line solution

HT-F9 as a high speed professional pick and place machine, it is mainly suitable for mounting a soft light belt, light tube and display screen. In the whole SMT production line, Considering the factors such as price and practicality, We mainly recommend a semi-automatic production line. The semi-automatic production line include semi-automatic stencil printer, conveyor, pick and place machine and reflow oven.

Related Machine

ETON is a manufacturing and process solution provider focusing on R&D, production, sales and service of SMT high-speed pick and place machines and SMT peripheral automation equipment. Besides pick and place machine, we also provide the SMT peripheral and related equipment, including PCB loader, PCB un-loader, stencil printer, conveyor, translational conveyor, pick and place machine, reflow oven and other peripheral automation equipment.

FAQ

1.What is the mainly difference between automatic line and semi automatic line ?

The big difference of automatic line and semi-automatic line is the price and the labor. Automatic line need higher cost but save much cost of labor. Usually one operator is enough. Although semi automatic line save the cost, it needs at least 2 workers.

2. Does your machines have quality certificates?

We are high-tech enterprise with CE, SIRA, CCC , ISO and have many technology patents. We also have 11 years experience in LED light SMT production line.

3. Can you support the whole SMT line?

A: Yes, we can provide the complete line solution including PCB loader, stencil printer, conveyor, pick and place machine, reflow oven and other peripheral automation equipment.

4. What advantages does your company have?

We have more than ten years of experience, with a large number of patents, software independent research and development, professional salesman and good after-sales service.

Contact us:

David Whatsapp/Wechat/Tel: +86 13827425982

E-mail:david@eton-mounter.com