Description

Machine main features

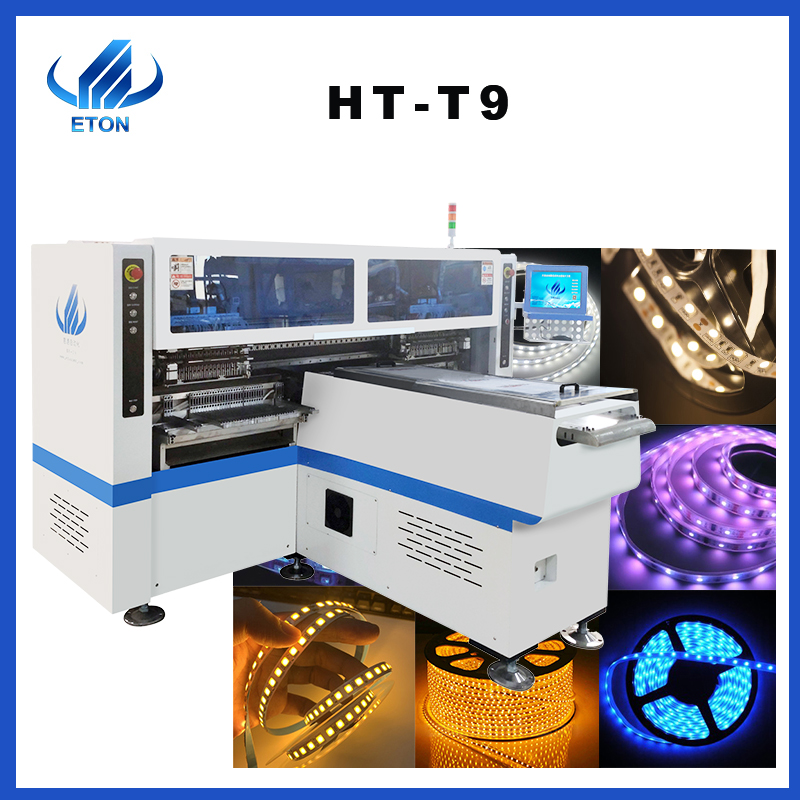

- Apply to the 0.6 m, 0.9 m, 1.2 m rigid PCB and 0.5 m, 1 m LED flexible strip, producing with 4 types materials at the same time with high capacity, available for board with any proportion of LED chip and resistor.

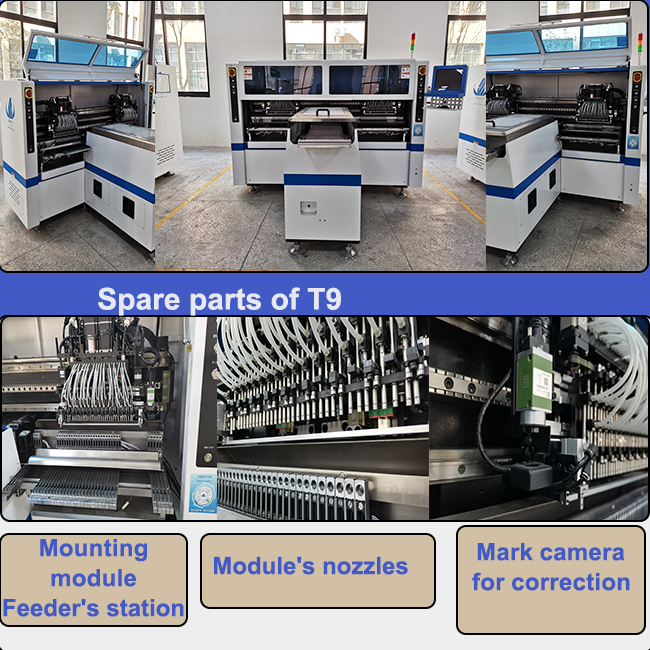

- Dual arm four module, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.

- IPC9850 capacity: 200000-250000 CPH

|

Model |

HT-F7S |

|

Dimension |

2700*2300*1550 mm |

|

Total weight |

1700 kg |

|

PCB length width |

Max: 1200*330 mm Min: 100*100 mm |

|

Mounting mode |

Group picking and group placing |

|

Mounting precision |

±0.02 mm |

|

Mounting speed |

150000-180000 CPH |

|

No. of head |

34 PCS |

Market

As a 11 years experienced company in SMT line, we have traded with more than 20 countries and regions with our machines, here are some of our partners:

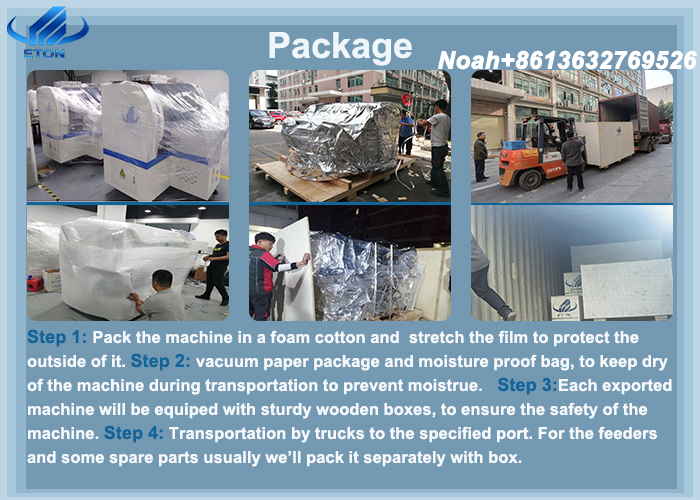

Packages

Packing of machine is to ensure the quality and safety of our machine to our clients, so that making sure of the safety of our machine is up to the good quality of package during transportation, here are the steeps:

Shipping and Delivery

Three ways as Air flight, land transportation and shipping by sea for different needs:

FAQ

Q.How can I make inspection when something wrong with the machine?

A. Well, the inspection is taken by our professional engineer to check and modulate the machine, if you counter any problem of our machine please contact us, and we will arrange our engineer to solve it.

Q. How is the differences of your multi-functional machine and high-speed machine?

A. The mounting mode of multi-functional and high speed machine which decides the range of their mounting products, and the mounting capacity is to distinguish this two types of the machine, such as multi-functional pick and place machine RT-1 with capacity of 40000 CPH, while high speed mounter machine HT-T9 with 250000 CPH capacity.

Q. How many products can your machine make per day?

A. The capacity of our machine is according to the real products, and the number of components on your PCB board that is important factor to figure out the actual speed of our machine with your products.