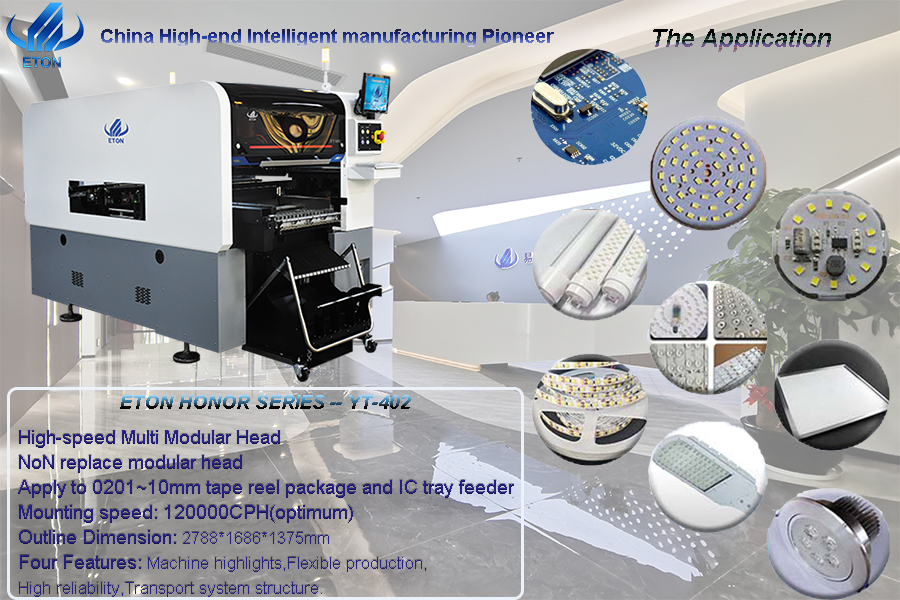

Description

Machine main features

- Adopt High speed multi modular head, apply to ultra small chip 0201~10*10mm large chip, widercomponent range;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum speed reach120000 CPH;

- Brand new self-developed high precision placement head;

- Combine highaccuracy Mark recognition camera with fixed flight vision camera, ensure placement accuracy;

- Docking Cart: Double side docking cart slot 32 PCS, tape reel package:64 PCS(Single docking cart slot 16 PCS, tape reel package:32 PCS)

- Smart Double-Head tape feeder: Support YT series double head intelligent electric tape reel feeder, by optically correcting the feeding position of the component, it can achieve stable, accurate and high-speed feeding;

- The placement head adopt independent vacuum detection, improve placement performance;

- Off-line programming, save time of changeover cycle;

- Software AI intelligent learning function and automatic optimization function.

- Two gantry, 20 spindles*2 Gantry, total 40 spindles;

- Flexible PCB handling capabilities, double rail, both gantry can mount the same large PCB at the same time, realizing flexible production.

Machine main parameter

|

Model |

YT-402 |

|

PCB size |

Max size: 500*450 mm(Single side) 500*300(Double side) Min size: 50*50 mm |

|

PCB thickness |

0.5-4.5 mm |

|

PCB clamping |

Cylinder clamping, track width adjustable |

|

Rail |

2 rail, 2 gantries(Rail 1,4 are fixed rail) |

|

Software |

R&D independently |

|

Production management MES system |

Customized (Option) |

|

Off-line programming |

Available |

|

Camera |

Head flight vision recognition component Vision alignment + Mark correction |

|

Repeat precision |

±0.02 mm |

|

Mounting height |

≦6 mm |

|

Position mode |

Optical |

|

Optimal speed |

120000 CPH |

|

Component range |

Min 0201~10 mm packages and IC etc. |

|

Position mode |

Optical |

|

No.of heads |

Double side:40 PCS Single side:20 PCS |

|

Feeding way |

Intelligent double head feeder |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor + Servo motor |

Machine Picture

Application products

It an mount high-precision products, such as displays, drivers, circuit boards etc.

Company profile

Shenzhen ETON Automation Equipment Co., Ltd., founded in 2011, is a provider focusing on the R & D,

production and sales of SMT high-speed mounter and SMT peripheral automation equipment, as well as

the manufacturing and process scheme of garment production. The company has SMT high-speed Mounter

business unit, precision solder paste printing equipment business unit, high-speed precision dispensing

defense business unit and SMT peripheral automatic makeup equipment business unit.

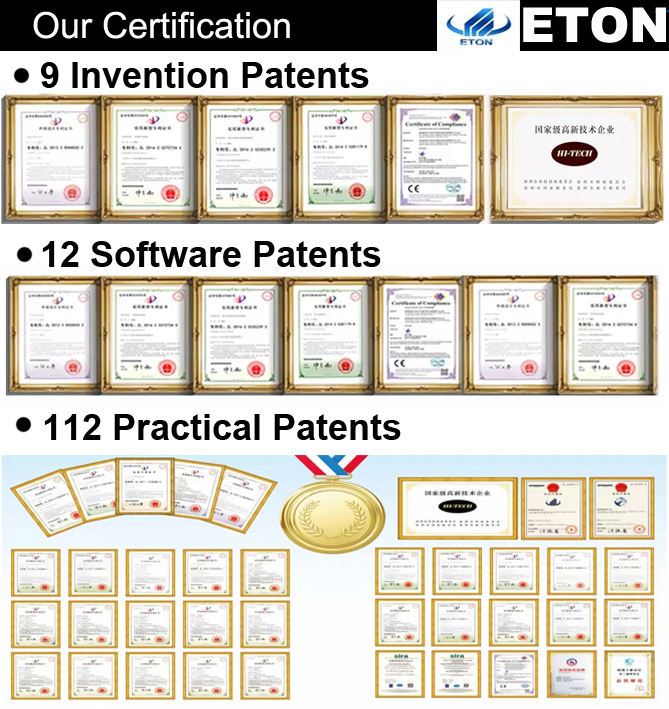

Certification:

We got 9 invention patents, 112 practical patents,12 software patents.

We are high-tech enterprise with CE,SIRA,CCC ,ISO awarded as “Well-know brand” and many technology patents, and have rich experience(more than 10 years) in LED light production line program.

Package and Delivery of Pick and Place Machine

Package advantages

Filming packing:Make the machine sanitary, clean, sealed packaging, dust and humidity; have good shock resistance, impact resistance, and good protection performance with tightness and fixity.

vacuum packing:Advantages of moisture proof,dust proof and so on.

wooden packing: It has good cushioning performance, corrosion resistance, high strength and hygroscopicity, moisture-proof and earthquake-resistant functions.

FAQ:

Q: What’s the terms of payment? What about the trade term?

A: T/T is OK. You can choose FOB Shenzhen.

Q: What’s your delivery time?

A: Usually 30 days after deposit, if we have inventory, the time can be brought forward.

Q: Is there any quality guarantee?

A: We stick to quality first, client-oriented, Continuous improvement!

Q: Is your software interface in English?

A: English interface and Chinese interface are both available.

Q: It’s hard to use the machine?

A: No, not at all. For our previous clients, at most 5 days is enough to learn to operate the machines.