Description

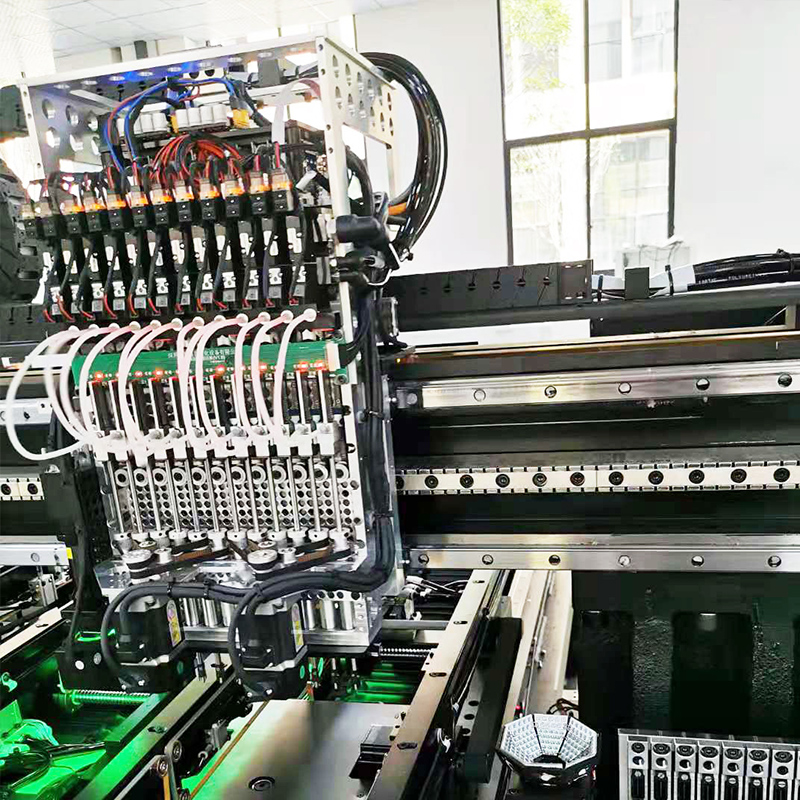

Pick and place Machine main features

1.Double module and produce 2 different products at the same time

2.4sets of camera and achieve flight identification and Mark correction

3.Adopt group to pick and separate to place, separate to pick and separate to place mounting mode

4.Have a wide range of applications: lighting (LED bulbs, tubes, panel light, street light, flexible strip), lens, household appliance, power driver and so on.

The main parameter of pick and place machine

|

Dimension : 3150 mm*2250 mm*1650 mm |

|

|

Total weight |

2500 kg |

|

PCB Length width |

Max: 1200*300 mm Min: 100*100 mm |

|

PCB Thickness |

0.5-5 mm |

|

Display |

Touch screen monitor |

|

Transmission speed |

≤1000 mm/sec |

|

Conveyor transmission |

Max length: 1200 mm |

|

Mounting precision |

±0.04 mm |

|

Component height |

<15 mm ( Automatic changing) |

|

Transmission direction |

Both direction (Option ) |

|

No. Of feeders station |

48 PCS Double module |

|

No. Of head |

24 PCS Double module |

|

Power consumption |

8 KW |

|

X, Y, Z Axis drive way |

High-end magnetic linear motor and serve motor |

The production line of HT-E8D PICK AND PLACE MACHINE

We not only provide pick and place machine, but also support professional SMT production line solution and SMT peripheral equipment, such as stencil printer, conveyor, reflow oven ,AOI, SPI, PCB loader, translational conveyor and so on.

Customer and factory

Our machines have been exported more than 20 countries and regions, such as India, Turkey, Egypt, Brazil, Iran, Tunisia and so on. We also help many factories to set up SMT production lines of all kinds of lights

Our Exhibitions

ETON is a well-known enterprise, and constantly participate in various domestic and foreign exhibitions, hoping to let more people know us, understand us.

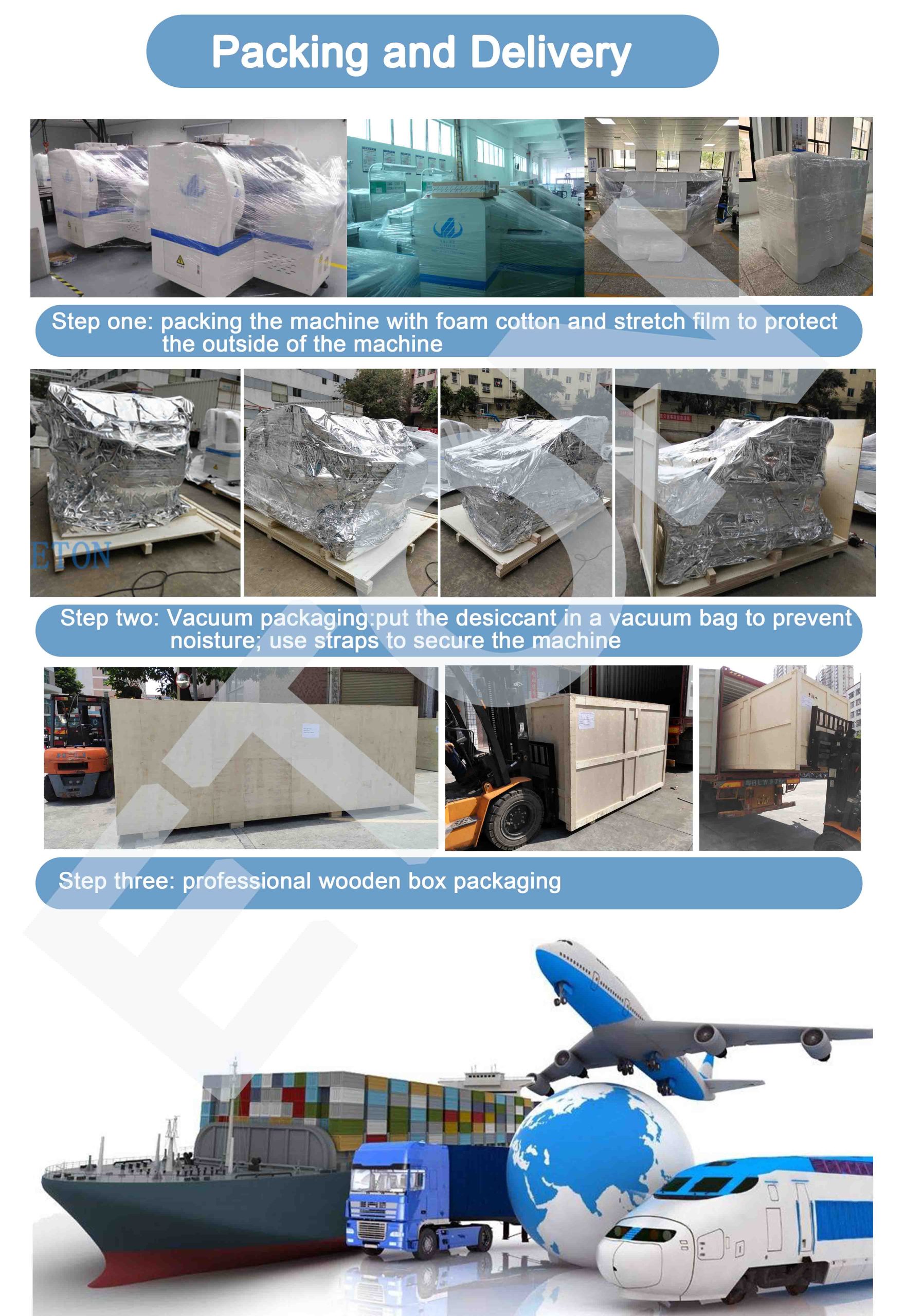

Shipping and Delivery

Our machines are suitable for sea, land and air transportation. Customers can choose according to their own needs. We will carefully inspect all parts of the machine before delivery to ensure that the machine arrives at the customer’s factory in good condition

Basic process elements of SMT:

Screen Printing (or dispensing) — Assembly — Solidification — reflow soldering — cleaning — Detection — Repair Screen

Printing: Its role is to solder paste or paste paste paste paste to the solder pad of the PCB, in preparation for the welding of components.

Dispensing: It is the glue drops to the fixed position of the PCB, its main role is to fix the components to the PCB board.

Mount: The function is to accurately mount the surface mount components to the fixed position of the PCB.

Curing: The function is to melt the SMT adhesive so that the SMT components are firmly bonded to the PCB board.

Reflow: its role is to melt the solder paste, so that the surface assembly components and PCB board firmly bonded together.

clean: The role is to assemble the PCB board above the harmful welding residues such as flux to remove.

testing: Its role is the assembly of a good PCB board for Welding Quality and assembly quality testing.

Repair: Its role is to detect the failure of the PCB board for Rework. The tools used are soldering iron, repair station and so on. In any position on the production line.