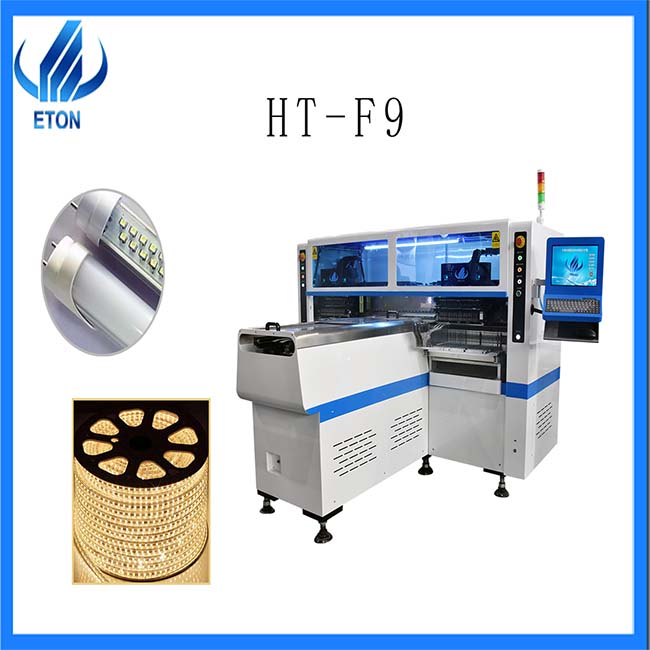

Description

Features

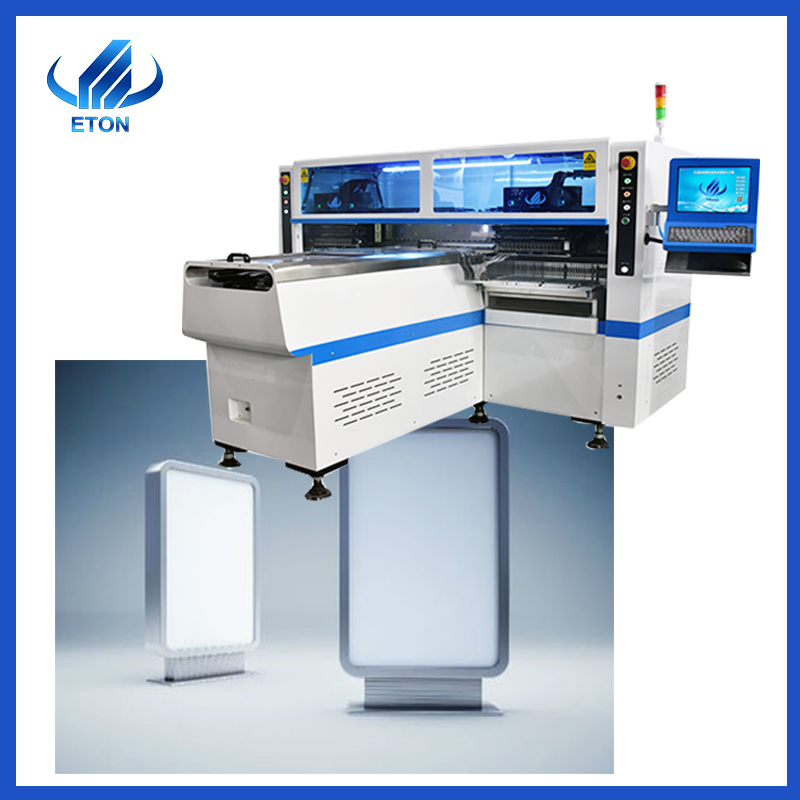

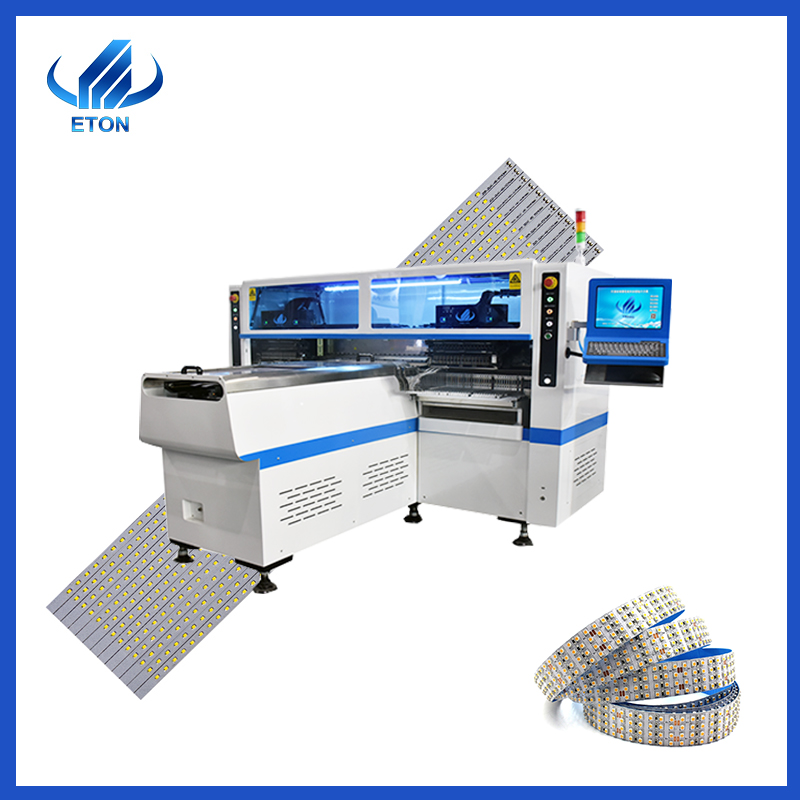

- apply to 0.6M,0.9M,1.2M rigid PCB and 0.5M,1M LED flexible strip.producing with 4 types materials at the same time with high capacity,avaible for board with any proportion of LED chip and resistor.

- Dual arm four module,17 nozzles for each mounting part,part A/B/C/D Can be mounted separately or synchronsly.

- Calibration automatically,high precision,available for RGB.

- Exclusive patent technology:Group to take and group to mount

Technical parameter

|

Dimension(L*W*H) |

2700*2300*1550mm |

|

Total weight |

1700KG |

|

PCB length width |

MAX:1200*330mm MIN:100*100mm |

|

PCB thickness |

0.5-5mm |

|

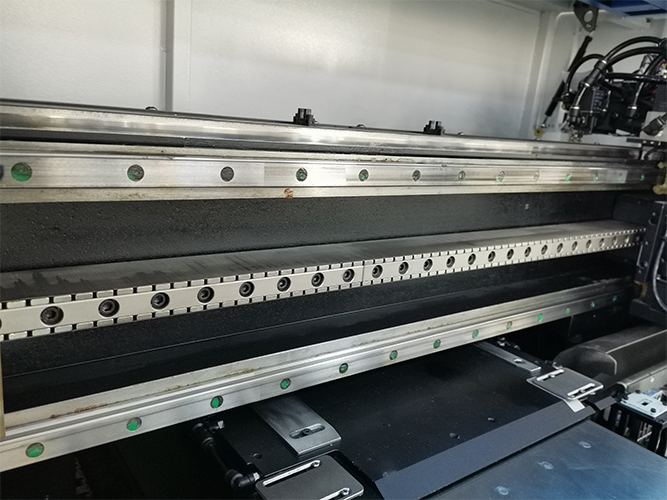

PCB clamping |

Adjustable pressure pneumatic |

|

Mounting mode |

Group to take and group to mount |

|

System |

Window7 |

|

Software |

R&D Independently |

|

Display |

Touch screen monitor |

|

Input device |

Keyboard,mouse |

|

No.of camera |

5PCS |

|

Repeat mounting precision |

+-0.02mm |

|

Mounting speed |

200000CPH-250000CPH |

|

Mounting height |

<=5mm |

|

components |

LED3014/3020/3528/5050 and resistor,capacitor,bridge rectifiers |

|

No.of feeders station |

68PCS |

|

No.of head |

68pcs |

|

Feeding way |

Electric feeder with double motor |

Company profile

Shenzhen ETON automation equipment Co., Ltd., founded in 2011, is a manufacturing and process solution provider focusing on the R &D, production, sales and service of SMT high-speed mounter and surrounding automation equipment. The company has SMT Mounter division, precision solder paste printing equipment division, high-speed precision dispensing equipment division and SMT peripheral automation equipment division.

Certificate of honor

FAQ

A:Did you develop your own machine?

B:It has independently developed the world’s first technological invention patents and proprietary technologies, including 9 invention patents, 12 software copyrights and 112 practical patents.

A:What is your machine suitable for?

B:Our machines are widely used in lighting, display screen, electronics, driving power supply, household appliances, new energy and other industries

A:It’s hard to use the machine?

B:No, not at all. For our previous clients, at most 5 days is enough to learn to operate the machines.