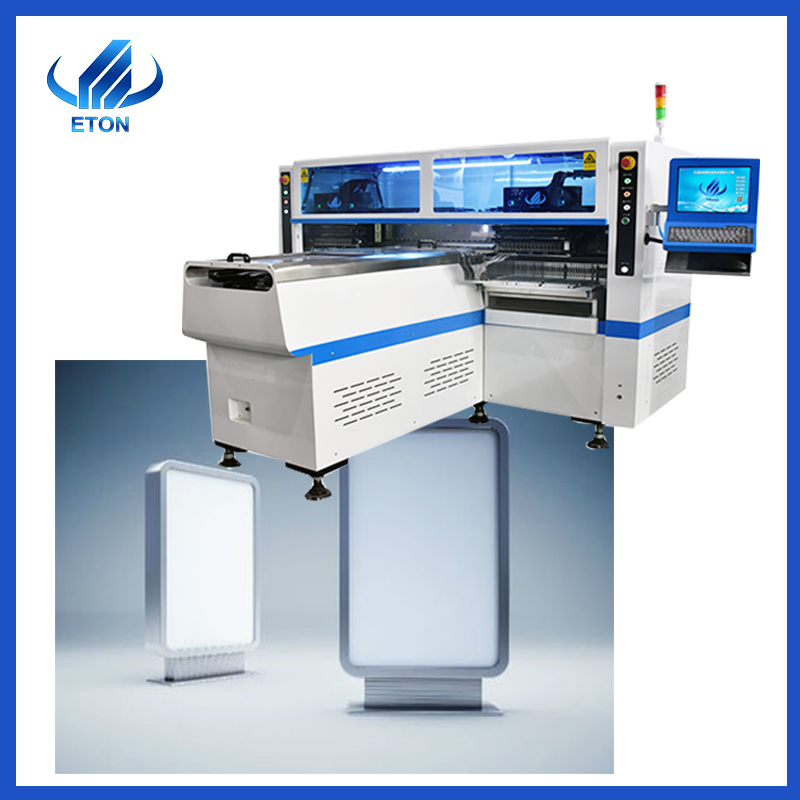

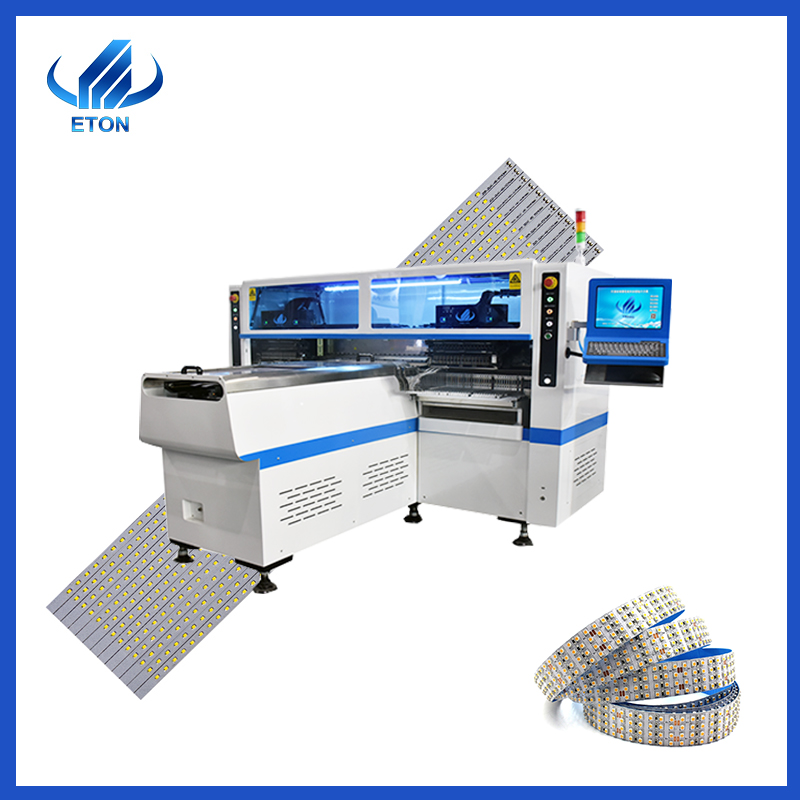

- Single module magnetic linear motor multifunctional pick and place machine.

- Mounting components:LED chip, capacitors, resistors, lens, IC, shaped components, etc.

- Component: Min. Size 0402, Max. Height 15mm.

- Application: Power driver, electric board, lens, DOB bulb, linear bulb, household appliance etc.

LED LIGHTING MAKING MOUNTING MACHINE

Description

Machine introduction

1.It has both high-speed and versatility, and realizes super practicality among products of the same level

2.The high-speed universal integrated mounting head does not need to be replaced. Each suction nozzle has an independent detection function to improve the stability of the equipment and the reliability of the product

3.Feeding device: feeder trolley, double headed intelligent feeder, IC backpack, realizing unequal material experience and stable production

4.The ultra-high speed head recognition camera is combined with the bottom flight recognition camera to ensure the mounting accuracy

5.Touch screen, the software supports Chinese and English, and the operation is simple and easy to understand

Component introduction

magnetic linear motor

lHere is the high-precision magnetic linear motor, which is used to improve the stability, speed and accuracy of machine placement. Our magnetic linear motor uses Israeli technology.

Grating scale

lThis is Grating scale, It is a detection device, which determines the accuracy of the head placement to a certain extent.

This Grating scale is RENISHAW/MicroE brand, from the UK and America.

Drag Chain

lThis is Drag Chain, The function is to protect the wires from abrasion and prolong the service life of the machine. It is made in Germany —- IGUS brand.

CAMERA

lOur YT202 pick and place machine has 4 cameras, It is a flight recognition camera and the Mark camera. This is the flight recognition camera, and this is the Mark camera. Their role is to improve The accuracy of machine placement. This is also one of the reasons why our multifunction machines can mount precision components.

MOUNTING HEAD

lLook here, each placement head of this multifunctional machine is controlled by an independent servo motor, which can mount different components.

guide rail

lThis is the guide rail, our PCB board is transported in from here. It comes from Japan, THK brand.

industrial computer

lThis is our industrial computer, EVOC brand, which is the TOP-2 Brand in the world. It is touch screen monitor, the software is independently developed by ETON, with a Chinese and English operation interface, and the operation is simple and easy to understand.

PARAMETER

|

PCB sized* W) |

Max size:500mm*450mm(single PCB) 500mm*300mm(double PCB) Min size: 50mm*50mm |

|

PCB thickness |

0.5-4.5mm |

|

PCB clamping |

Cylinder clamping, track width adjustable |

|

Rail |

2 Rail,2 gantries(Rail 1,4 are fixed rail) |

|

System |

Windows 7 |

|

Software |

R&D independently |

|

Production management MES system |

Customized(Option) |

|

Off-line programming |

Available |

|

No. of camera |

4 sets (数字相机 Digital camera ) |

|

Bottom vision camera recognition |

|

|

Vision alignment+Mark correction |

|

|

Repeat precision |

± 0.02mm |

|

Mounting height |

w20mm |

|

Mounting speed |

80000CPH (Optimum speed) |

|

Components range |

0201〜40*40mm Min 0201 ~40*40mm Tape reel packages and IC tray feeder etc. |

|

Power |

380AC 50HZ 6KW |

|

Operating environment |

23°C 土 3°C |

|

Transmission direction |

Standard: Single direction |

|

Transmission mode |

Online drive |

|

Position mode |

Optical |

|

Air consumption |

0.4-0.6mpa ( 4-6kgf/cm2) 150N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 1 set |

Independent research and development by ETON |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor +Servo motor |

|

No. of Feeder station |

Double side docking cart slot 32PCS,tape reel packages:64PCS(single side docking cart slot 16PCS,tape reel packages:32PCS),freely switching between docking cart and IC tray feederdC tray feeder:Option) |

|

No. of Heads |

20PCS/Double side:20pcs(single side:10pcs) |

|

Feeding way |

Intelligent Double head Feeder |

SMT PRODUCTION LINE

FAQ

Q: How about the after-sale service? How about the warranty?

A: We have a team of professional engineers to solve your problems. Any parts that require repair and replacement are free ofcharge during the warranty period. We can also provide you with training and on-site installation, and support remote control of the machine, the machine uses Chinese and English interface, very easy to operate.

Q: Are you a trade company or a manufacturer?

We are an professional manufacturer specialized in Screen Printer,SMT Machine, Pick and Place Machine, Reflow Oven, SMT Production line and other SMT Products.

Q: What is your delivery date?

The delivery date is about 20 days upon the full payment.

Q: What is your payment terms?

A:100% payment before delivery or 50% deposit in advance and the rest before shipment.