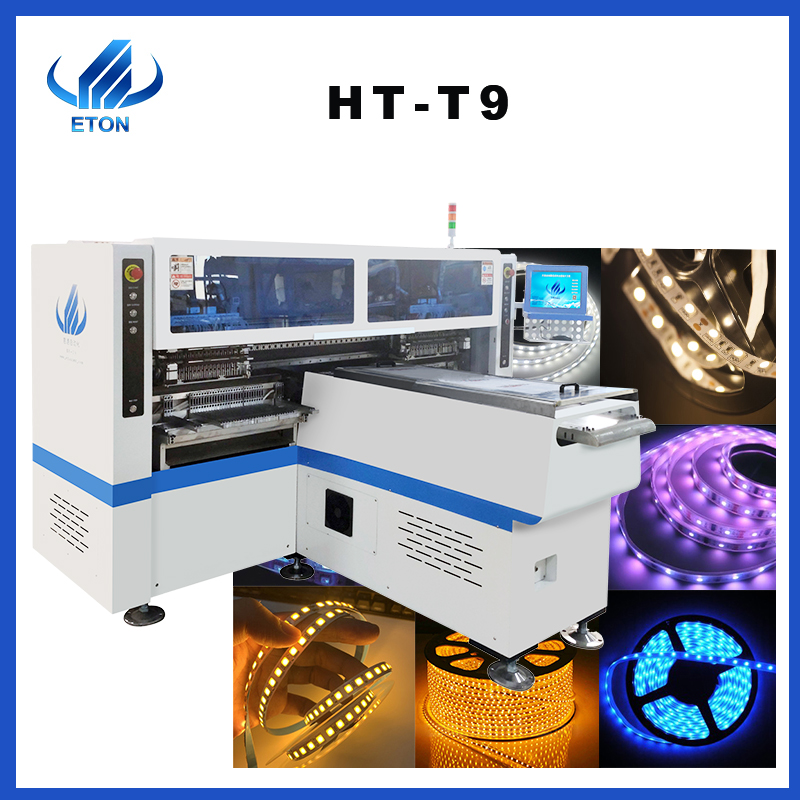

The biggest feature of HT-E8S-1200 single module is that it is suitable for a variety of products.,12 PCS of heads, 28 PCS of feeders station with mounting speeds up to 45000 CPH. Not only can mount LED bulbs, street light, table light, down lights, power driver, electric board, lens and so on, but also display screens and linear products, such as LED tube, flexible strip.

LED lighting SMT pick and place machine of 12 heads

Description

The features

1. The biggest feature of HT-E8S-1200 single module is that it is suitable for a variety of products.,12 PCS of heads, 28 PCS of feeders station with mounting speeds up to 45000 CPH. Not only can mount LED bulbs, street light, table light, down lights, power driver, electric board, lens and so on, but also display screens and linear products, such as LED tube, flexible strip.

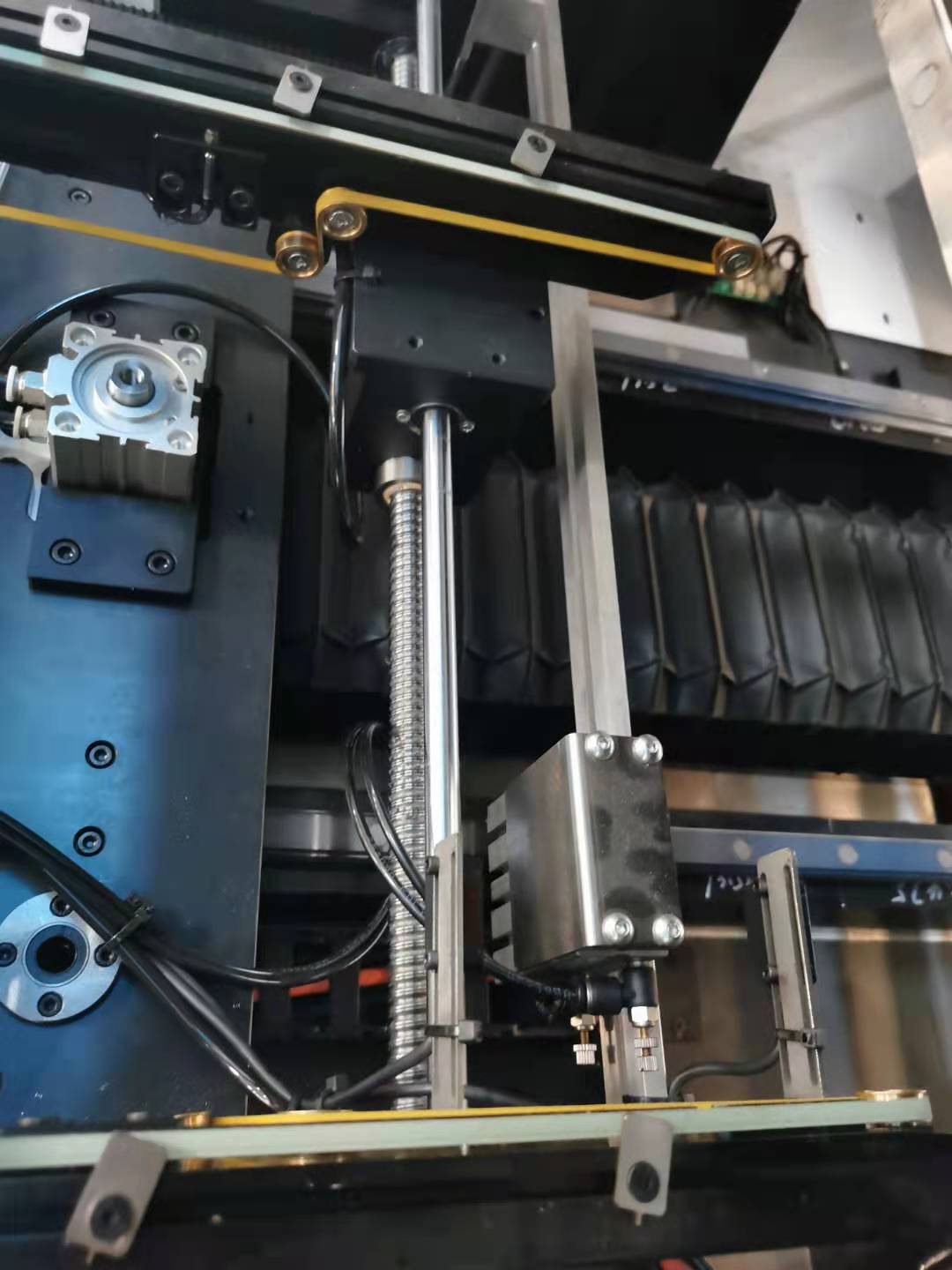

2. The exclusive patented technology includes: electronic feeder feeding system, vision alignment flight identification, mark correction, non-stop material re-loading function,auto-optimization after coordinates generated.

The technical parameter

|

Total weight |

1700 kg |

|

PCB Length width |

1200*500 mm-100*100 mm |

|

PCB Thickness |

0.5-5 mm |

|

Feeding way |

Electric feeder with double motor |

|

Mounting precision |

±0.04 mm |

|

Conveyor transmission |

Max length: 1200 mm |

|

Transmission speed |

≤ 1000 mm/sec |

|

Component space |

0.2 mm |

|

Component height |

<15 mm ( Automatic changing) |

|

Transmission direction |

Both direction (Option ) |

|

No. Of feeders station |

28 PCS Single module |

|

No. Of head |

12 PCS Single module |

|

Operating environment |

23℃±3℃ |

|

Power consumption |

4 KW |

|

X, Y, Z Axis drive way |

High-end magnetic linear motor and serve motor |

The related equipment

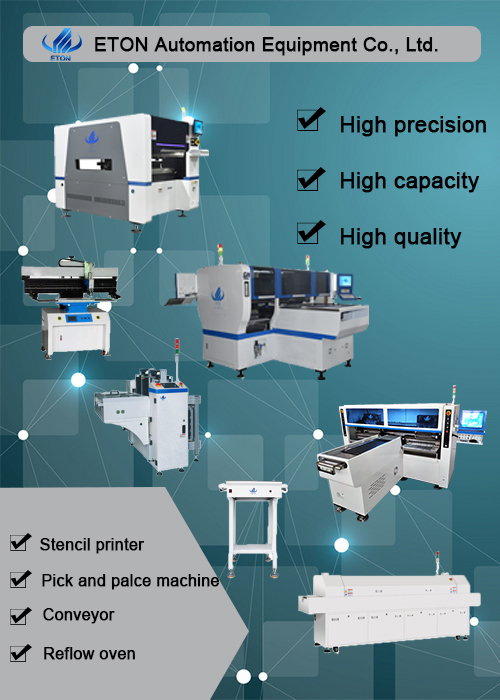

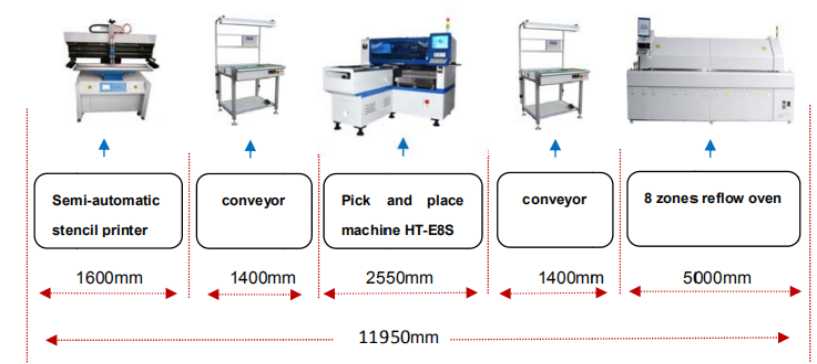

Not only we provide pick and place machine, but also we have the machine of a complete SMT production line. Such as loader machine, stencil printer ( semi automatic and full automatic), conveyor, reflow oven and other equipment. We will provide complete and suitable SMT process solution. For example HT-E8S-1200, thinking the cost and other factor, we will recommend the semi automatic SMT production line, including semi-automatic stencil printer, 1.4 M conveyor, pick and place machine, 8 zones reflow oven.

The SMT production line

The semi-automatic production line include semi automatic stencil printer, conveyor, reflow oven.

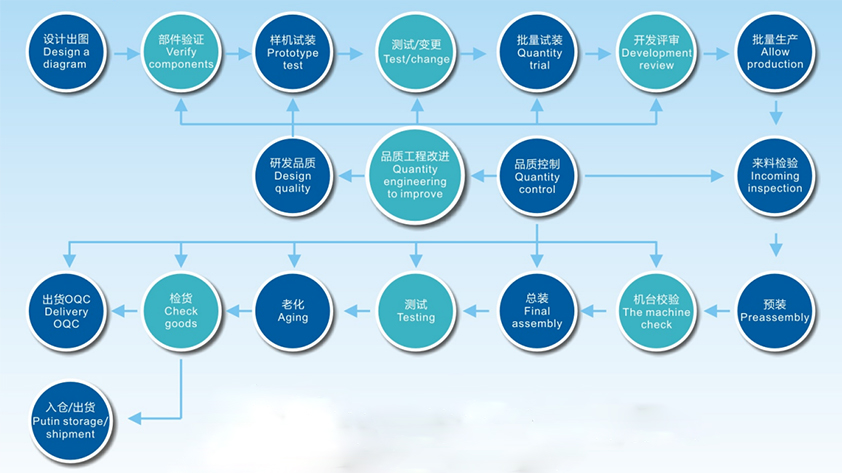

Quality control

We have perfect and strict quality control process. From design a diagram to put storage / shipment, every step is strict control, to ensure the quality of equipment.

Maintenance period 1 year

- One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

- Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

- Visit clients regularly. We attend the different exhibitions in different cities. every year, at the same time, we will visit local

clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

- We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

- We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

- According to your, needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine

- .