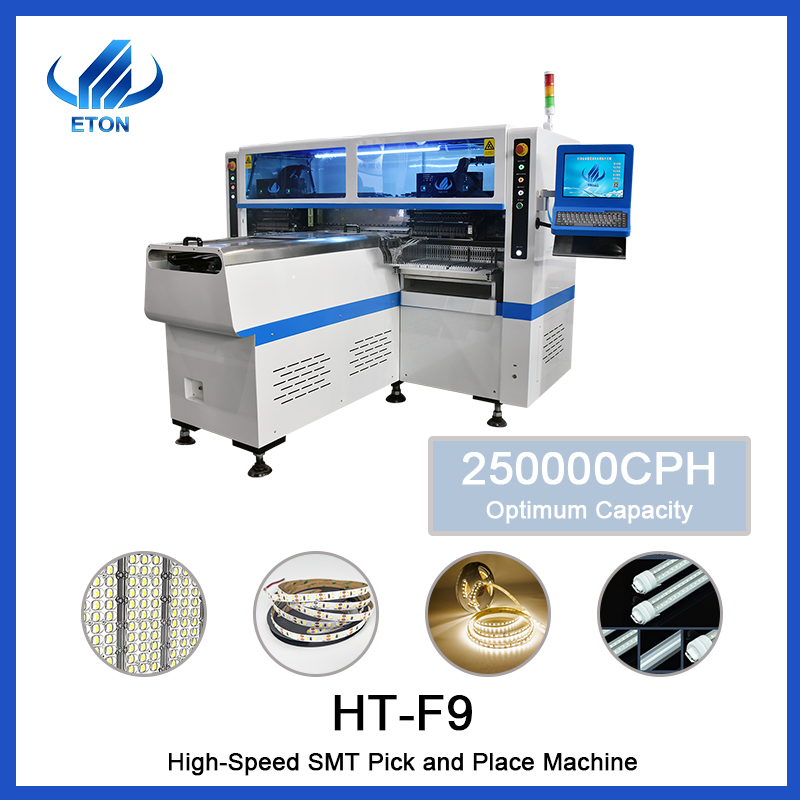

The Machine parameter of HT-F9 pick and place machine

Dimension

2700mm*2300mm*1550mm

PCB Length width

Max: 1200*330mm Min: 100*100mm

PCB Thickness

0.5-5mm

PCB clamping

Adjustable pressure pneumatic

Conveyor transmission

Max length: 1200mm

Component space

0.5mm

Component height

≤5mm

Operating environment

23℃±3℃

Power consumption

6KW

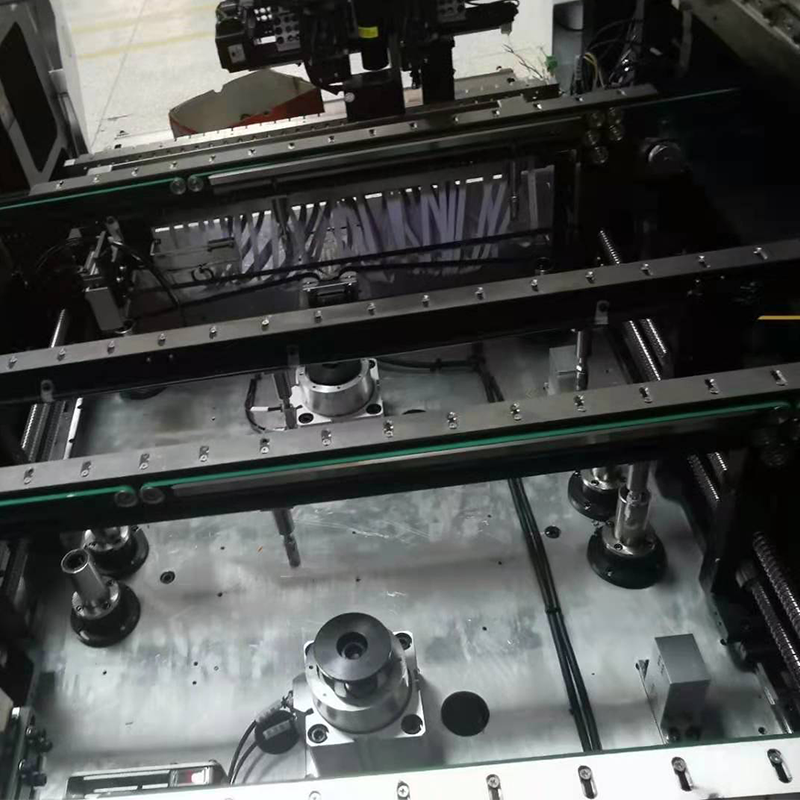

X, Y, Z Axis drive way

linear motor and serve motor

No. Of feeders station

68PCS

No. Of head

68PCS

Feeding way

Electric feeding with double motor

The advantages of HT-F9 pick and place machine

1.68 heads, two mounting module, each mounting module has 34 heads;

2.68 PCS of feeder station, adopt electric feeder with double motor feeding way

3.Adopt group picking and group placing mounting mode, achieve high mounting speed;

4.high-end magnetic linear motor and servo motor

5.produce 4 types materials at the same time, Optimum mounting speed reach 250000 CPH.

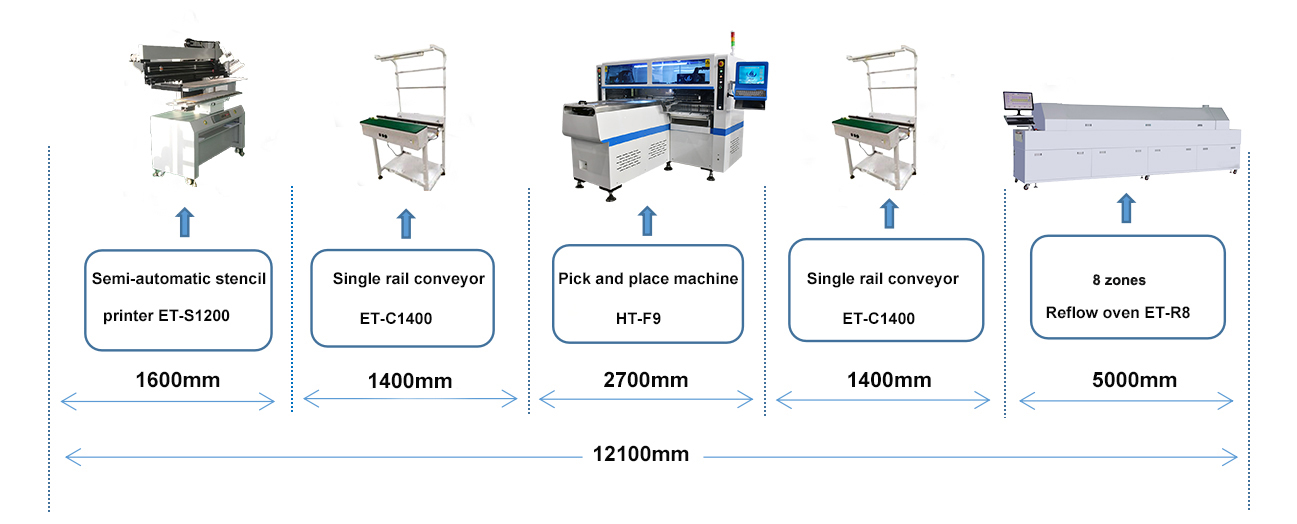

The semi-automatic Production line of HT-F9 pick and place machine

the total length of HT-F9 pick and place machine is about 12.1 meter.including semi-automatic stencil printer, pick and place machine, conveyor and reflow oven

ETON also supply whole SMT production line machine, mainly included : Loader, Automatic stencil printer, Semi-automatic stencil printer, Conveyor, Pick and place machine, Reflow oven machine, Un-loader machine, etc.

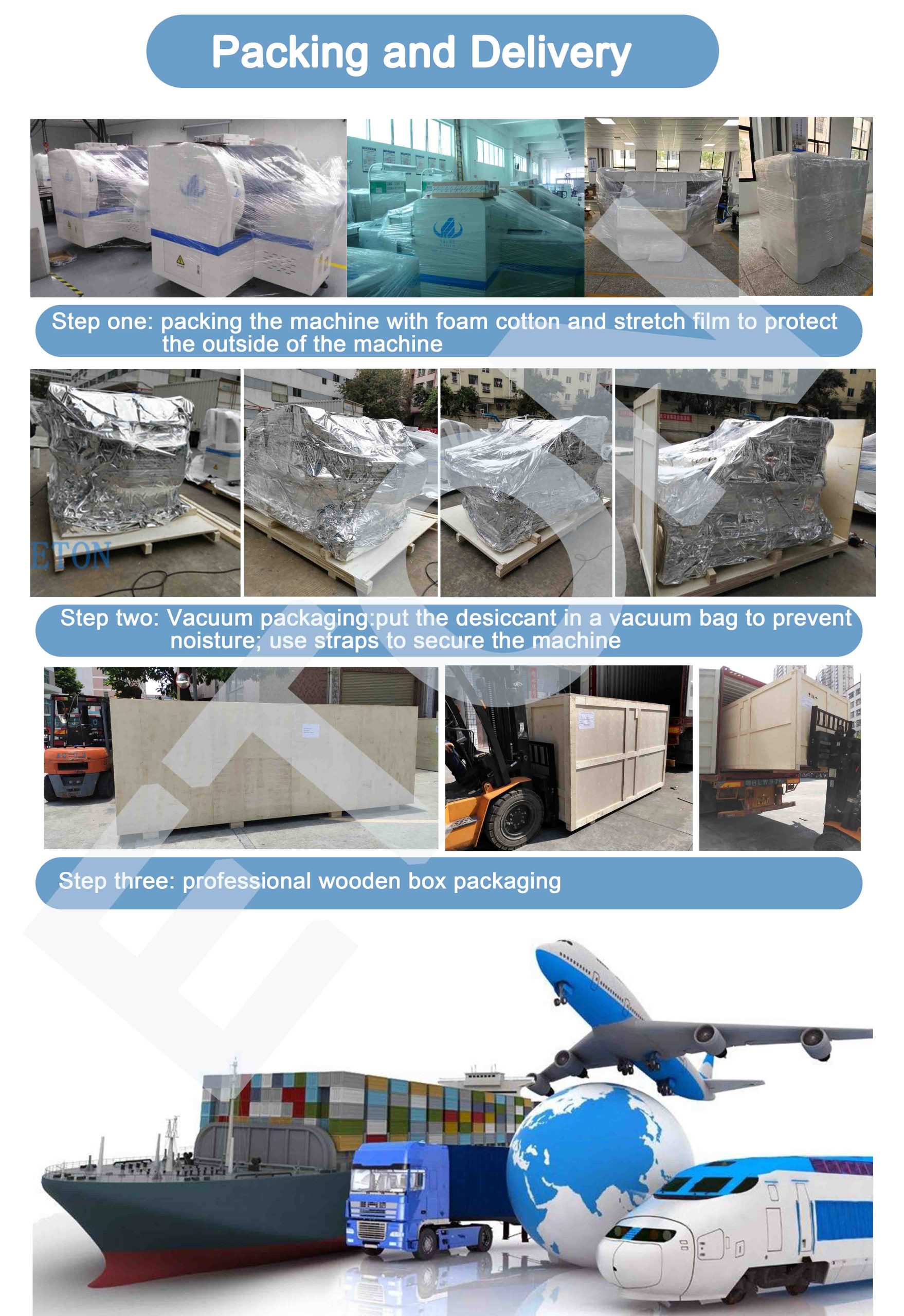

Package and transport

we use the vacuum packaging and wooden box packaging.

First, Wrap the machine in foam cotton and stretch film to protect the outside of the machine

Second, Vacuum packaging, put the desiccant into a vacuum bag to prevent moisture, and use straps to fix the machine;

Third,professional wooden box packaging.

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities. every year, at the same time, we will visit local

clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your, needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.