YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

E8s-600 introduction

Ht-e8s-600 single-mode magnatic multi-functional high-speed Mounter single-mode group 12 suction nozzles and 28 Feida high-speed mounters. The optimal production capacity per hour is 45000cph. The mountable parts include belt mounted light beads, capacitors, resistors, IC, special-shaped components, up to 17mm and at least 0402, which can be perfectly mounted with various drives, power supplies, circuit buttons, lenses, linear bulbs, home appliance control boards and other products. The patch method is to take the light paste in groups and take the light paste separately. The software independently developed by windows7 system can touch screen display, which makes it easy to operate, faster to use and better mounting effect.

Parameter

|

Model |

HT-E8S-600 |

|

Length |

1550 mm |

|

Width |

1650 mm |

|

Height |

1550 mm |

|

Total Weight |

1500 kg |

|

PCB |

|

|

PCB Length Width |

Max:600*500mm Min:100*100mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Adjustable pressure pneumatic |

|

Mounting Mode |

Group picking and separate placing\separate picking and separate placing |

|

Vision System |

|

|

No. of Camera |

2 sets of imported camera |

|

Vision for the flight identification, MARK correction |

|

|

Mounting Precision |

±0.04mm |

|

Mounting Height |

<15mm (Automatic Changing) |

|

Mounting Speed |

45000 CPH |

|

Components |

LED , capacitors, resistors, IC,shaped components, etc. |

|

Components Space |

0.2mm |

|

No. of Feeders Station |

28 PCS |

|

No. of nozzles |

12 PCS |

|

Electrical control |

Independent research and development by ETON |

|

X,Y,Z Axis Drive way |

High-end magnetic linear motor + Servo motor |

|

Feeding way |

Electric feeder with double motor |

APPLICATION

E8s is suitable for mounting a variety of products, such as panel lamp, display screen, driving lamp tube, lamp belt, etc.

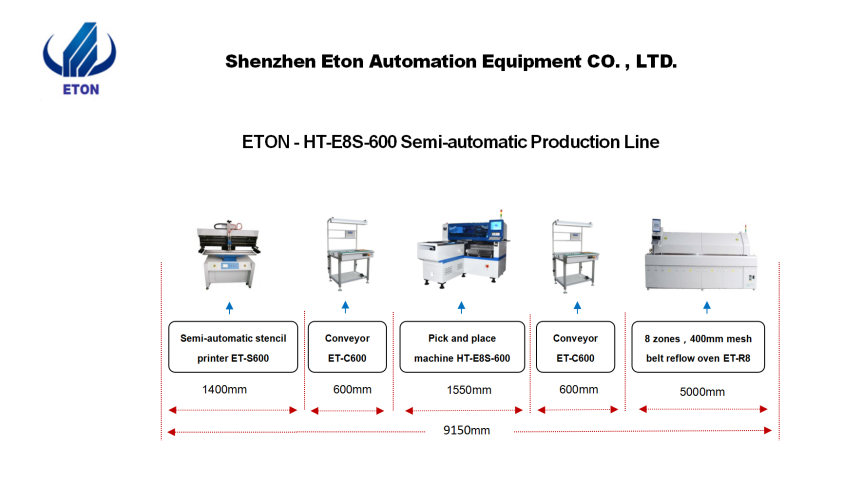

SMT LINE

Services

1.Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free

2.Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates

3.Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time

4.Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

5.On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt. Turkey that can provide service timely with our engineers.

According to your needs. dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

FAQ

Q: How is the training?

A: After purchasing our products, you can send your engineers to study in our factory, or we can send our engineers to yourfactory to train your staff for you .

Q: Do you have a product certification certificate?

A: Our products have CCC, CE, SRIA certification.

Q: How about the after-sale service? How about the warranty?

A: We have a team of professional engineers to solve your problems. Any parts that require repair and replacement are free ofcharge during the warranty period. We can also provide you with training and on-site installation, and support remote control of the machine, the machine uses Chinese and English interface, very easy to operate.