Description

Machine Features:

1.Apply to the 0.6m,0.9m,1.2m rigid PCB and 0.5m,1m LED flexible strip. Producing with producing with 4 types materials at the same time with high capacity, available for board with any proportion of led chip and resistor.

2.Dual arm four module, 17 nozzles for each mounting part, part A/B/C/D can be mounted separately or synchronously.

3.Exclusive patent technology: Group to take and group to mount.

4.5 cameras, 2 feeder debugging cameras, 2 nozzle debugging cameras, one Mark camera, high placement accuracy.

5.The mounting speed reached 200000~25000CPH.

6.The software, circuit and hardware structure of the whole machine are all independently developed by our company, with independent intellectual property rights.

Machine main parameter:

|

Model |

HT-F9(Dual arm magnetic linear LED high speed pick and place machine |

|

Dimension(L*W*H) |

2700*2300*1550mm |

|

Weight |

1700kg |

|

PCB thickness |

0.5~5mm |

|

Mounting precision |

±0.02mm |

|

Mounting mode |

Group to take and group to mount |

|

Components |

LED3014/3020/3528/5050 and resistor, capacitors,bridge rectifiers |

|

Mounting height |

≤5mm |

|

Mounting speed |

200000~250000 CPH |

|

NO.of camera |

5PCS(Digital camera) |

|

No. Of feeders station |

68 PCS |

|

No. Of head |

68 PCS |

|

X,Y Axis drive way |

High-end magnetic linear motor+servo motor |

|

Feeding way |

Electric feeder with double motor |

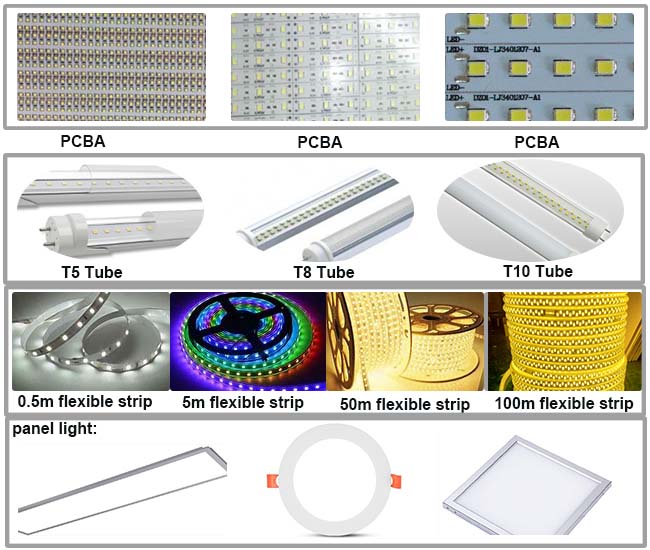

Application:

This machine suitable for mounting 0.5m,1m, 1.2m hard light board or any length of flexible strip. It can produce

Linear products such as lamp tube, flexible strip ,panel light, display screen and so on.

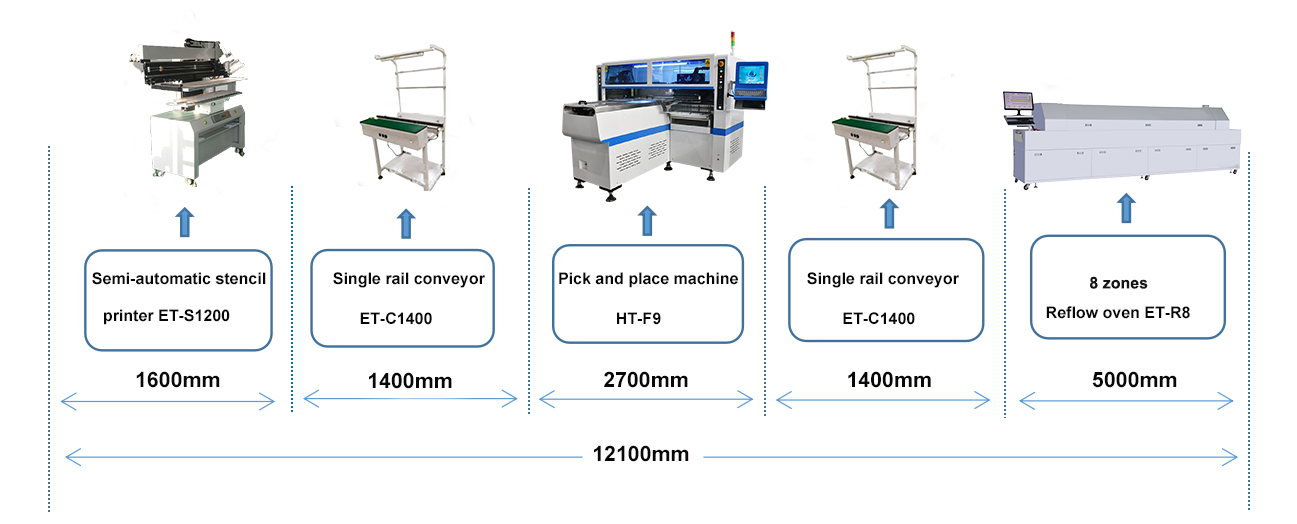

SMT Production line:

|

1 |

Solder paste printer Machine(Solder paste printing): The solder paste or patch glue is leaked onto the pads of the PCB board to prepare for the next step of soldering the components. |

|

2 |

Conveyor : transmission the PCB board to pick and place machine, at the same time, It is used for connection between SMT production lines and can also be used for buffering of flexible strip PCB boards. |

|

3 |

Pick and place machine HT-E8S-1200: Accurately mount surface mount components to fixed positions on the PCB board. |

|

4 |

Conveyor: transmission the PCB board to reflow oven.At the same time, It is used for connection between SMT production lines and can also be used for buffering of PCB boards. |

|

5 |

Entering the reflow oven:Melt the solder paste or die glue to firmly bond the components to the driver board. |

|

6 |

Test: Testing whether the product performance is intact(manual inspection) |

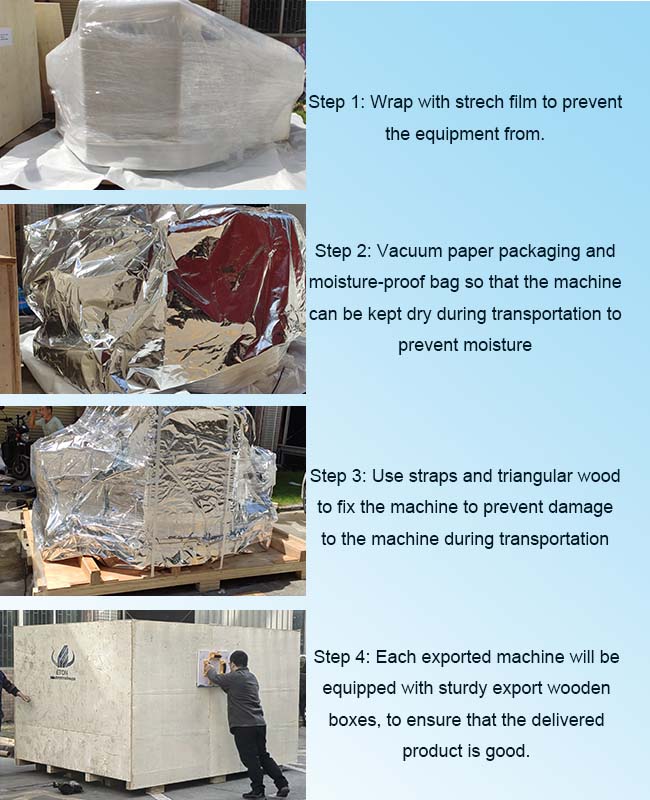

Packing:

Our Advantages:

1.We are leading manufacturer of automatic high speed pick and place machine.

2.80% large and listed led factory are our client.We have over decades development history.

3.We have an industrial park covering an area of 50,000 square meters in jiangxi, which has various machine.

4.We have world record-breaking high speed pick and place machine, which speed reached 500000CPH.

5.We have local India engineer, As long as you buy the machine, we will arrange engineers to install, debug and training you for free, until you learn to operate the machine, service is very convenient. We

have offices in Mumbai and New Delhi, very quick to support.

FAQ:

1..Do you have overseas engineers?

Yes, of course. We have local engineers in India, If you have any problem about machine, we can send India engineer to solve the problem for you.

2.How can I buy this machine from you?

a.Consult us about this product on line or by e-mail.

b.Negotiate and confirm the final price , shipping , payment methods and other terms.

c.Send you the proforma invoice and confirm your order.

d.Make the payment according to the method put on proforma invoice.

e.We prepare for your order in terms of the proforma invoice after confirming your full payment.

3.Which countries are your machines mainly sold to?

Our products exported to more than 20 countries and regions, including Turkey, Egypt, India, Pakistan, South Africa, Brazil etc.

4.What’s the terms of payment?

T/T is OK.30% Down payment in advance,70% payment before delivery.