- Group to take and group to place patent

- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 5 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

LED Tube PCB mount making machine

Description

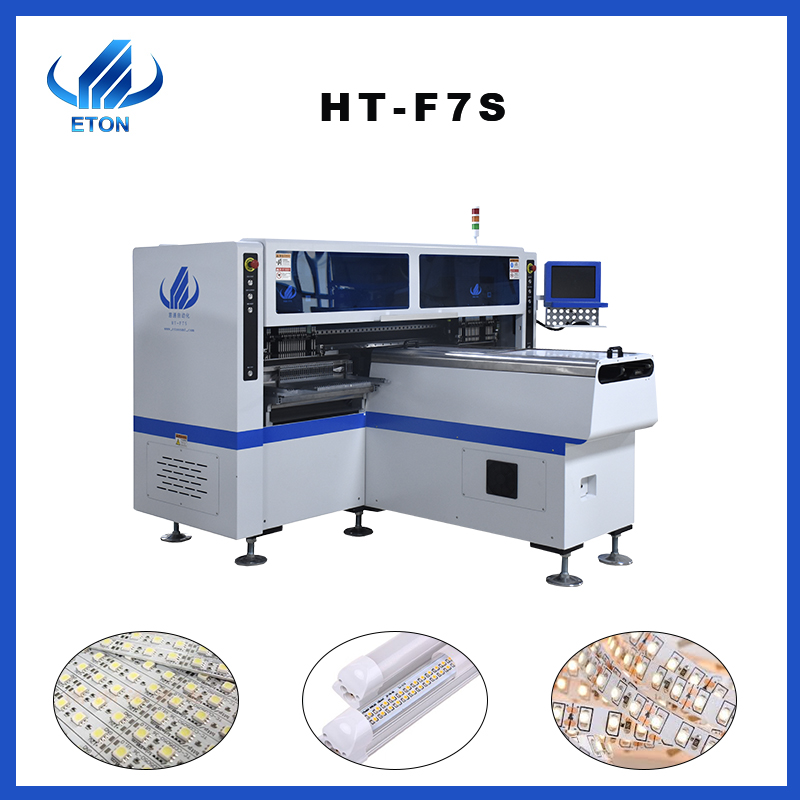

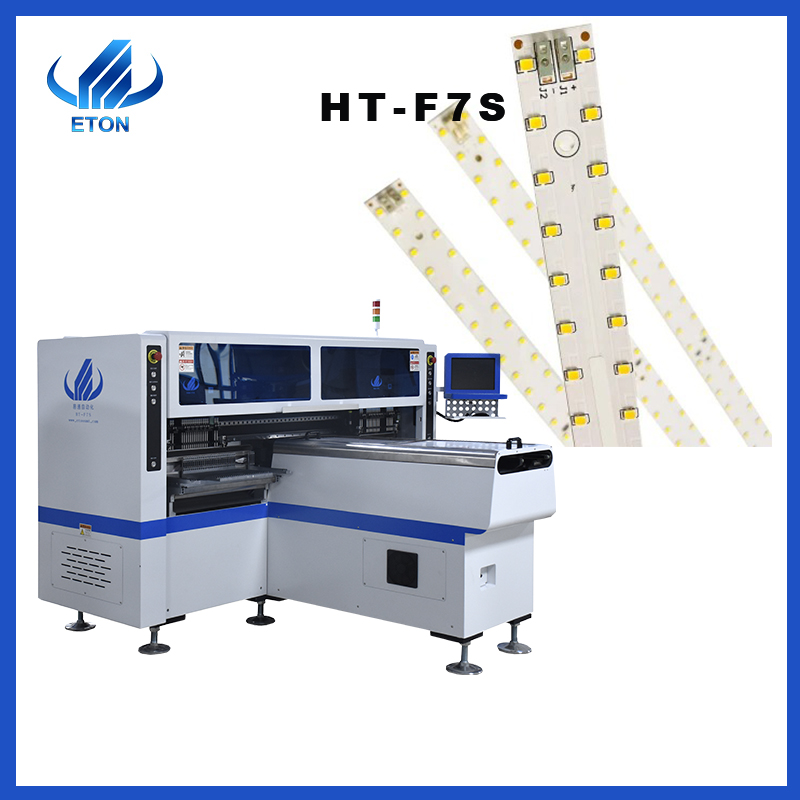

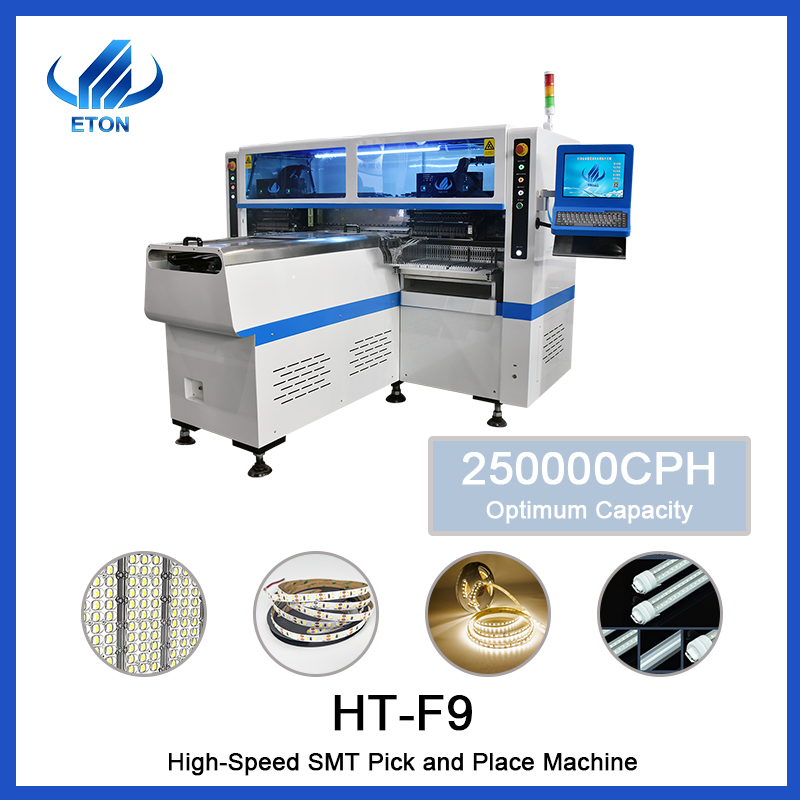

F7s introduction

1.The simultaneous production of a variety of materials does not affect high production capacity. It is suitable for 0.6, 0.9, 1.2 meter hard light panels and 0.5/1 meter soft light strips

2.Double arm special high-speed chip mounter, 34 suction nozzles and 68 Feida, making the mounting speed up to 150000-180000cph

3.Hikvision camera, the top domestic brand, and five sets of cameras, including visual alignment camera and mark correction camera, are used to improve the mounting accuracy

4.Linear motors are used for X and Y axes, with higher mounting accuracy, faster speed and longer service life

Equipment required for making lamp tubes

1.Printing machine: solder paste is missed on the solder pad of PCB

2.Docking station: transmission PCB board, with buffer function

3.Mounter: mount components to the designated position of PCB

4.Reflow soldering: heating is the melting of solder paste, so that PCB and components can be better adhered

The most critical step is the placement, which is to ensure the quality of the entire PCB

The raw materials to be prepared include solder paste, lamp beads, PCB board lamps

Our market

Domestic market: in China, we help 80% of people build factories, and the scale is large, such as MLS, opple, NVC, etc; Every year, hundreds of our machines are sold abroad. Undoubtedly, there are many customers, including rk, rangdong, calcom, polyca, Surya, etc.

Maintenance period 1 year

- One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

- Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

- Visit clients regularly. We attend the different exhibitions in different cities. every year, at the same time, we will visit local

clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

- We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

- We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service

timely with our engineers.

- According to your, needs, dedicated senior engineer will come to your factory for free install and training you how to

operate the machine.

FAQ

Q: How is the training?

A: After purchasing our products, you can send your engineers to study in our factory, or we can send our engineers to yourfactory to train your staff for you .

Q: Do you have a product certification certificate?

A: Our products have CCC, CE, SRIA certification.

Q: How about the after-sale service? How about the warranty?

A: We have a team of professional engineers to solve your problems. Any parts that require repair and replacement are free ofcharge during the warranty period. We can also provide you with training and on-site installation, and support remote control of the machine, the machine uses Chinese and English interface, very easy to operate.