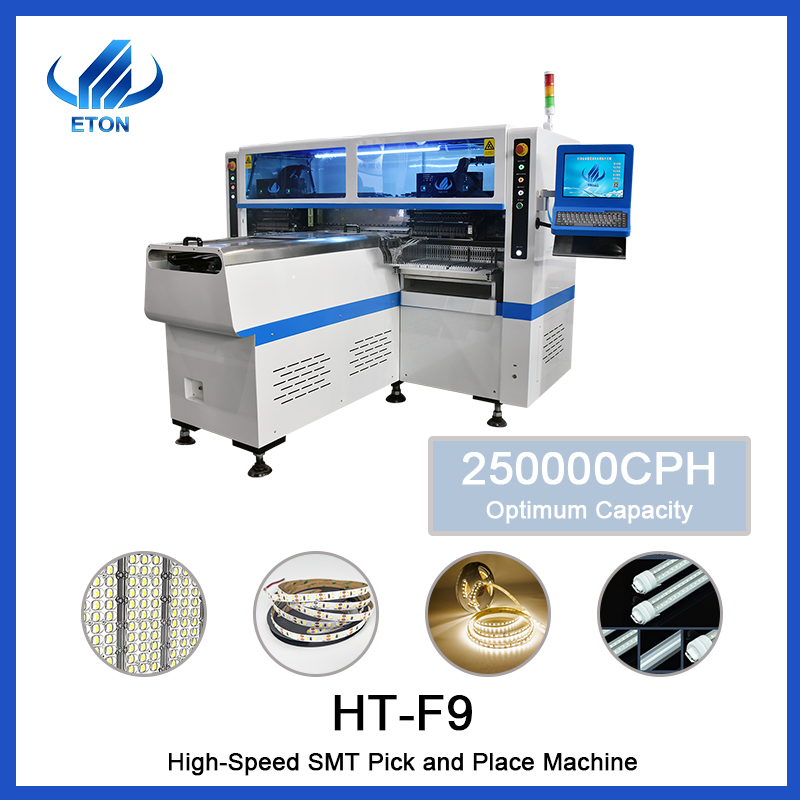

Fast mounting efficiency and high mounting accuracy–HT-E8D-1200/HT-E8D-600

Light SMT mounting machine

Description

Machine main parameter

|

No. of Camera

|

4 sets of imported camera |

|

Vision for the flight identification, MARK correction |

|

|

Mounting Precision |

±0.04mm |

|

Mounting Height |

<15mm (Automatic Changing) |

|

Mounting Speed |

90000 CPH |

|

Components |

LED , capacitors, resistors, IC,shaped components, etc. |

|

Components Space |

0.2mm |

|

No. of Feeders Station |

48 PCS |

|

No. of nozzles |

24 PCS |

|

Power |

380AC 50HZ |

|

Power Consumption |

8 KW |

|

Operating Environment |

23℃±3℃ |

|

Conveyor transmission |

Max length :1200 mm |

|

Transmission Speed |

>1000mm/sec |

|

Transmission Direction |

Both direction (option) |

|

Transmission Mode |

Auto online drive |

|

Air supply |

0.4-0.6mpa (4-6kgf/cm2)300N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 2 set |

Independent research and development by ETON |

|

X,Y,Z Axis Drive way |

High-end magnetic linear motor + Servo motor |

|

Feeding way |

Electric feeder with double motor |

HT-E8D is a dual-mode multi-function machine. Each module has a set of programs to control independently.

HT-E8D-600 and HT-E8D-1200 two kinds of module, suitable for most factories’ needs.

The speed reaches 90000cph,48 PCS Mounting heads.

Feature of HT-E8D

- PCB Max size:1200*300mm

- Non-stop material re-loading function

- Automatic optimization after coordinate generation

- Two different products can be installed at the same time

- Support customization, such as the number of heads, PCB board size, etc

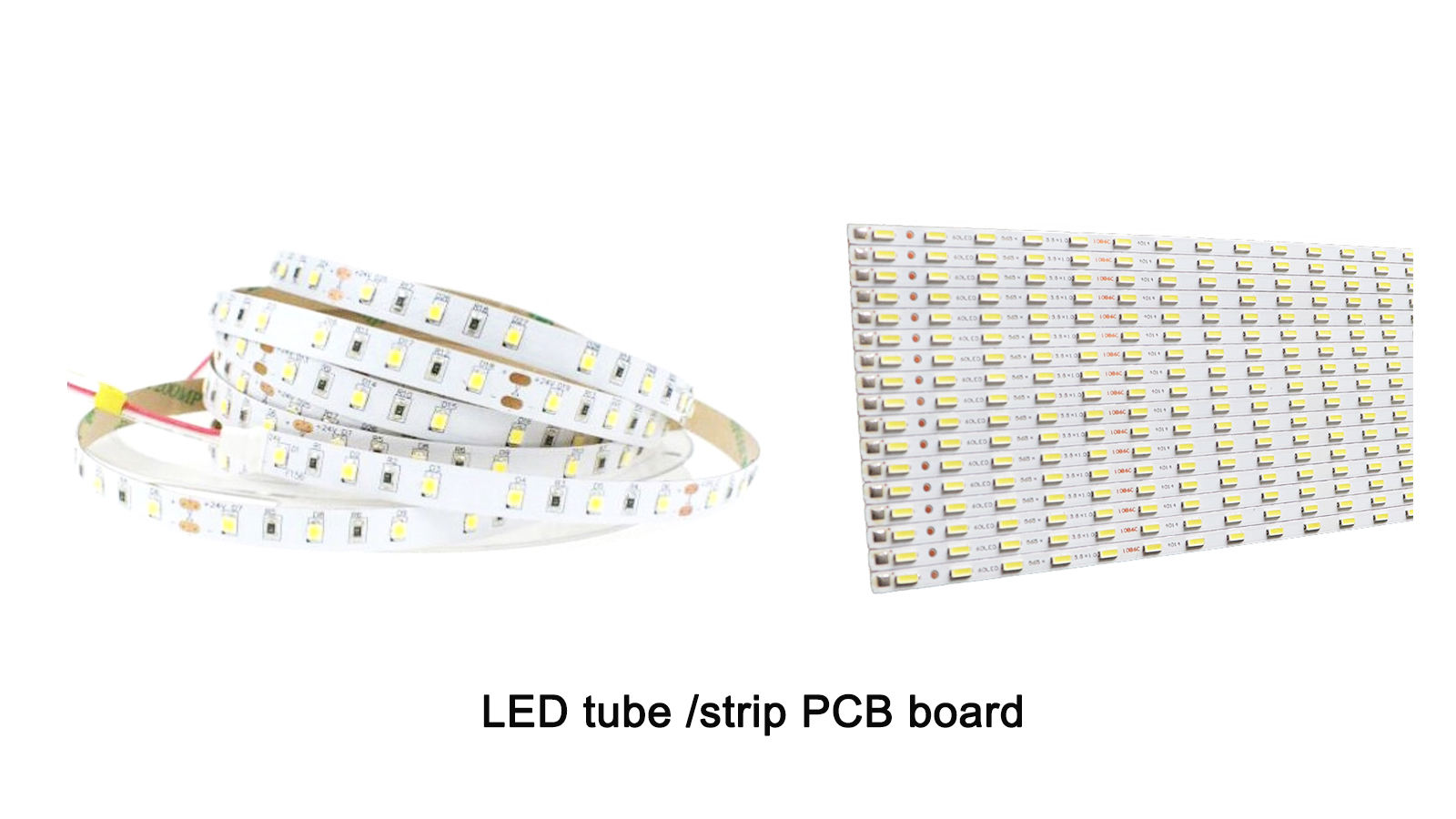

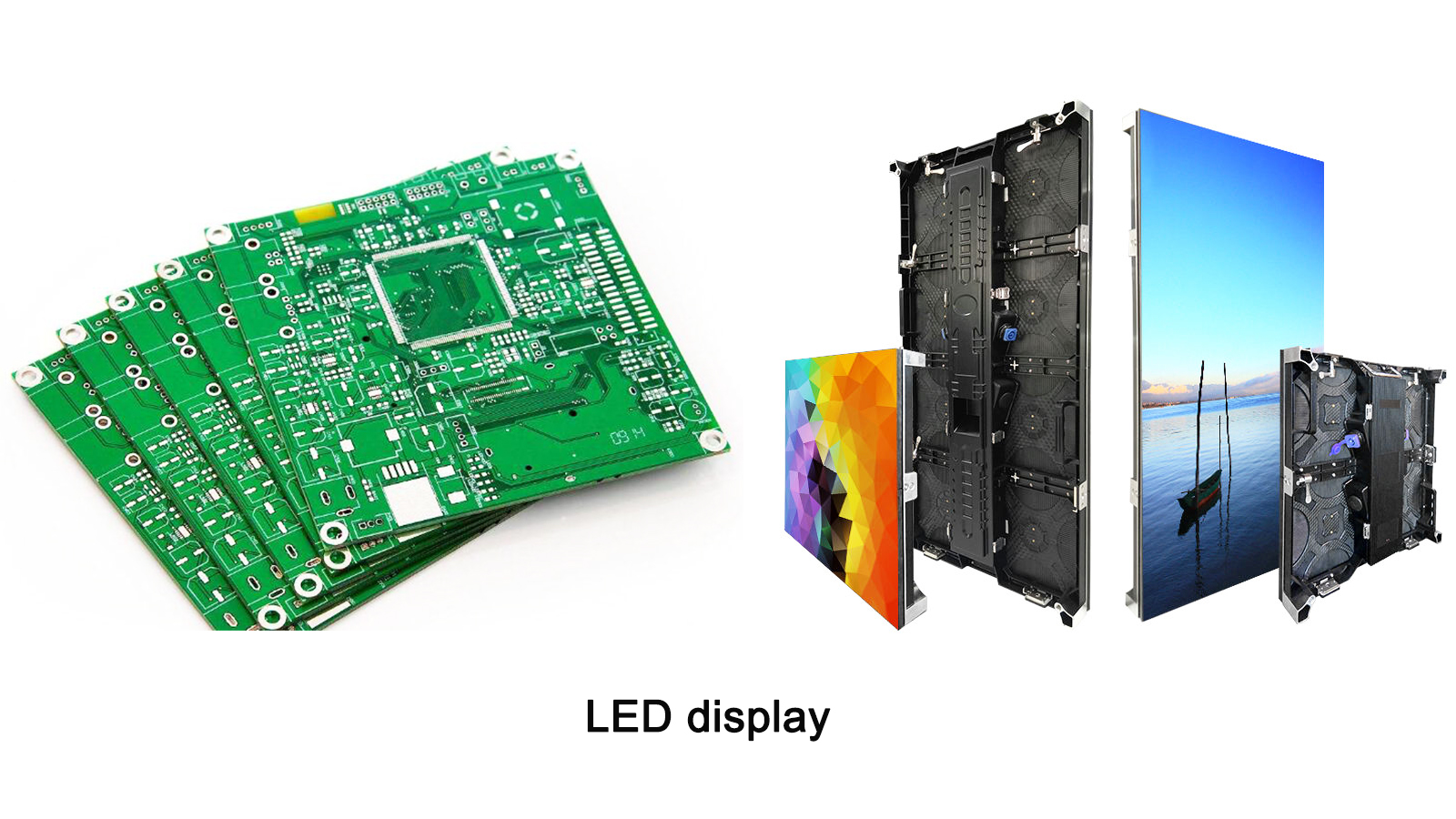

Applicable to a variety of production scenarios:

It can mount capacitors,resistors,LED3014/3020/3528/5050,IC and shaped components. It applies to power driver,electric board,lens,linear bulb,household appliance and etc.

With such high speed, applicability, practicability and versatility, it has become one of the most popular machines.

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.