Description

Parameter

|

model |

YT 101S |

|

PCB size |

MAX size: 500*350mm MIN size: 50*50mm |

|

PCB thickness |

0.5-4.5mm |

|

PCB clamping |

Cylinder clamping, track width adjustable |

|

rail |

Rail 1 is fixed |

|

system |

Windows 7 |

|

software |

R&D independently |

|

Production management MES system |

Customized(option) |

|

Off-line programming |

available |

|

No. Of camera |

2 set (digital camera) |

|

Head flight vision recognition component |

|

|

Vision alignment+ mark correction |

|

|

Repeat precision |

±0.02mm |

|

Mounting height |

≦20mm |

|

Mounting speed |

40000 CPH(optimum speed) |

|

Components range |

Min 0201-40*40mm packages and IC etc |

|

Power |

380AC 50HZ 4KW |

|

Operation environment |

23℃±3℃ |

|

Transmission direction |

Single (left-right, right-left) |

|

Transmission mode |

Online drive |

|

Position mode |

optical |

|

Air consumption |

0.4-0.6mpa()4-6kgf/cm2) 150N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 1 set |

|

|

X,Y,Z Axis drive way |

High end magnetic linear motor+ servo motor |

|

No. Of feeder station |

Station:16 pcs, tape reel packages 32 pcs |

|

No. Of heads |

10 pcs |

|

Feeding way |

Intelligent double head feeder |

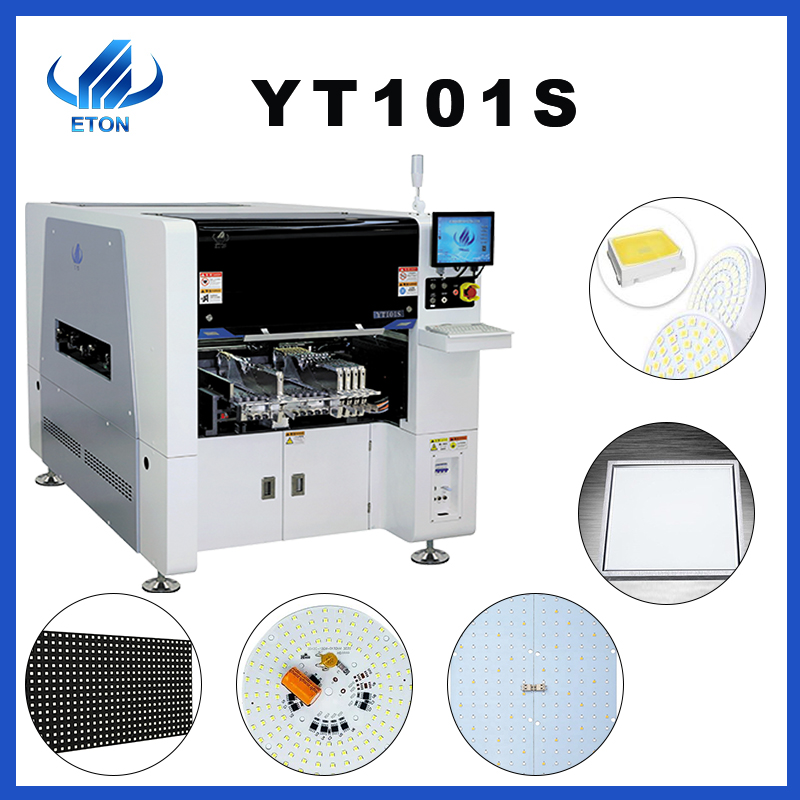

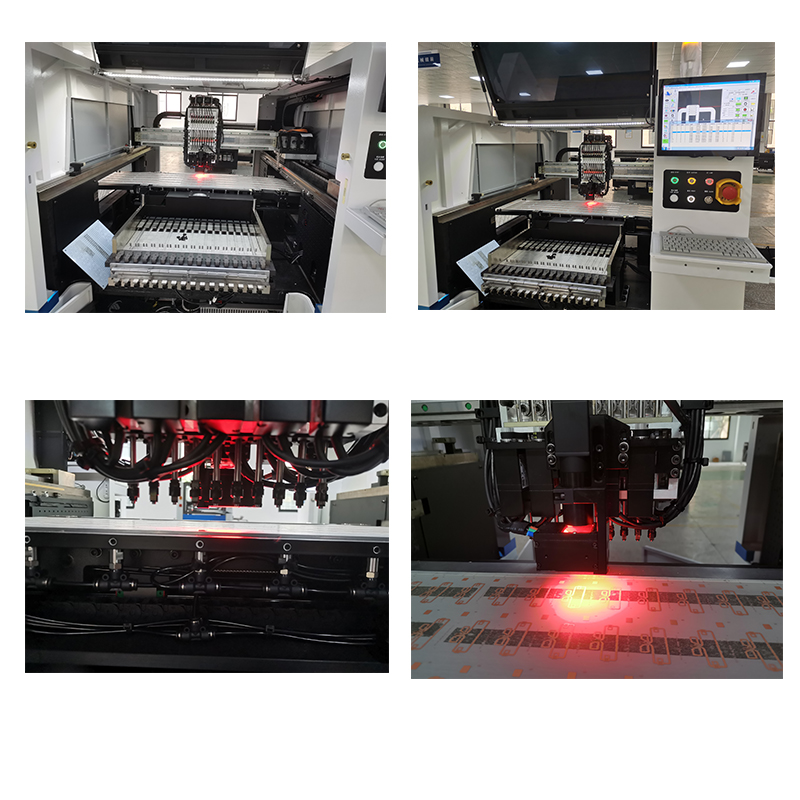

Features

1.High speed and intelligent, ultra performance

adopt high speed multi modular head, apply to ultra small chip 0201-40*40mm large chip, wider component range

improve recognition performance size up to 40*40mm, apply to BGA 0R CSP etc.

each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product.

optimum placement speed reach 40000 CPH.

2.flexible productionand high reliability

(1)fixed flight vision recognition camera(option)

(2)intelligent and smart double head tape feeder

(3)brand new self-developed high precision placement head

(4)combine high accuracy, mark recognition camera with fixed flight vision camera, ensure placement accuracy

(5)the placement head adopt independent vacuum detection improve placement performance

(6)off-line programming, save time of changeover cycle

(7)software AI intelligent learning function and automatic optimization function

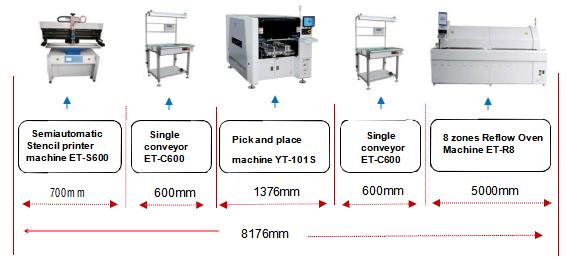

The production line

We provide the whole SMT production line: semi-automatic and full-automatic.

for semi-automatic production line, it includes semi automatic stencil printer, single-rail conveyor, pick and place machine, reflow oven

Company advantages

ETON is the top manufacturer of SMT pick and place machine in china, was founded in 2011 with more 10 years experience in SMT machine.

ETON is a manufacturing and process solution provider focusing on R&D, Production, sales and service of SMT high-speed pick and place machines and SMT peripheral automation equipment.

The machine update and update, has a high stability.

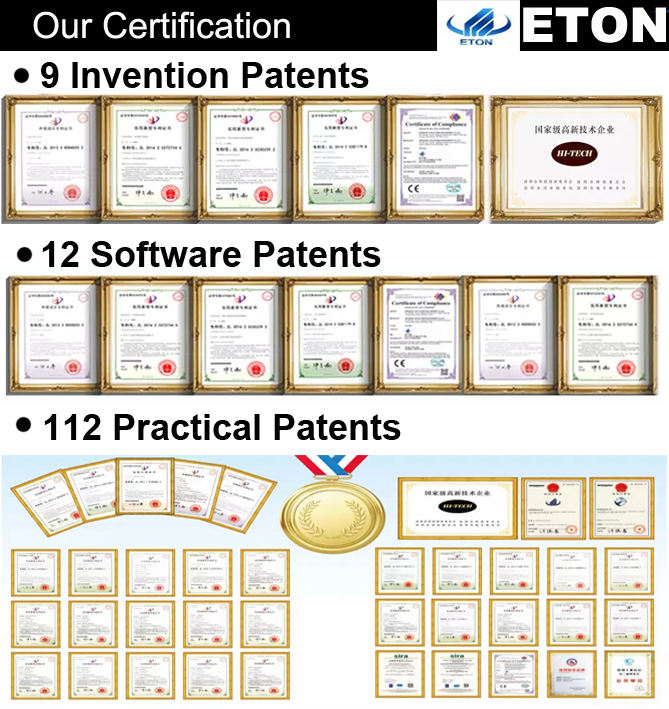

Certificates

133 invention patents and property technology patents, including We got 9 invention Patents, 112 practical patents, 12 software copyrights.ETON is leading position in the filed of SMT pick and place machine, aim to “Create a well-known national brand and build a word-class enterprise”.

The service and transport

1.The Service

Before sales

Our sales specialist will analyze and recommend the equipment and production line best for you and Provide exclusive and customized services

Under sales

Specialist sale tracks the equipment production and transport situation in time, ensure that the equipment arrives at customers in good condition, and provide professional technical guidance for equipment assembly, and part of areas provide door-to-door service for overseas engineers

After sales

One-year warranty period, sales specialist to answer questions online 24 hours; regularly visit customers to understand the working status of equipment.

2. The package and transport

In order to ensuring the machine in good condition when arrive the equipment reaches the customer factory, we use the vacuum packaging and wooden box packaging.

Step 1: pack the machine with foam cotton and stretch film to protect the outside of the machine

Step 2: Vacuum packing. Put the desiccant in a vacuum bag to prevent moisture; use straps to secure the machine;

Step 3: professional wooden box packaging.