Description

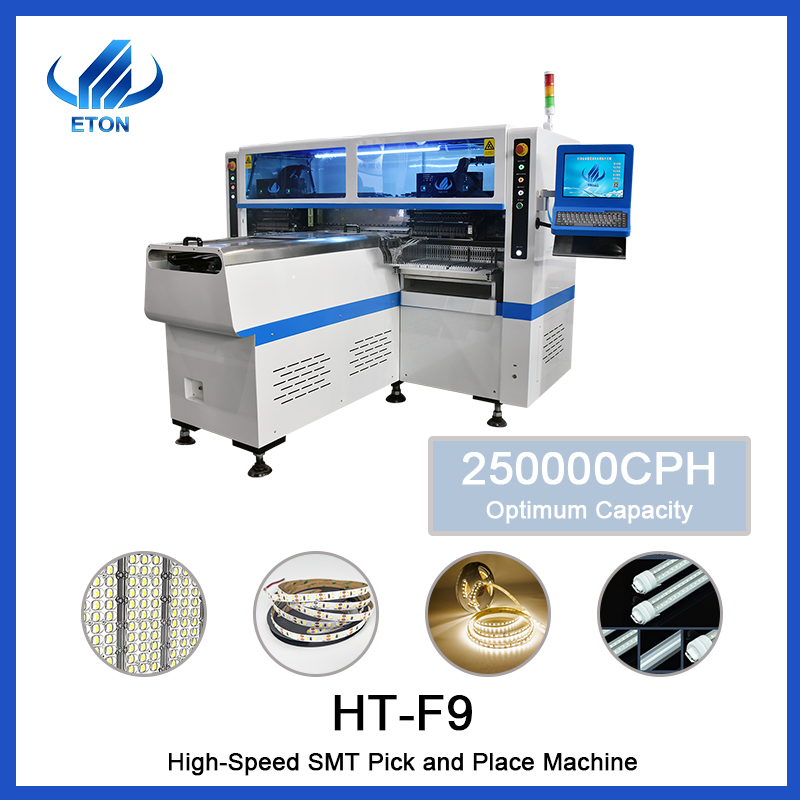

Machine description:

1.YT 202S is one of the newly launched YT series products from ETON. The dual-module placement machine can produce two identical PCB boards at the same time, improving production efficiency.

2.Under optimal conditions, the production capacity can reach 80000CPH, and the precision is very high, and the minimum mounted components can reach 0201.

Machine Feature:

1.Machine head:

(1).This machine adopted High-speed multi modular head(NON replace modular head),apply to ultra small chip 0201~40*40mm large chip,wider component range.

(2).It equipped with 20 heads, Each placement head with independent detection function,which improves the stability of the equipment and the reliability of the product.

(3).Adopt High-end magnetic linear motor,servo system and multi function modular head, the optimum placement speed reach 80000 CPH.

2.Machine camera:

The No.of camera is 4 sets digital camera, head flight vision recognition component, vision alignment, mark correction

3.Feeding system:

(1).The machine is equipped with a special docking cart. The double-sided station has 32PCS, which can load 64 trays of materials, and the single-sided station has 16PCS and can load 32 trays of materials.

(2).Smart YT Series Double-head intelligent feeder, , realizes high-speed and stable feeding through optical correction.

(3).Support multi-layer IC Tray feeder, realize easy completion of alternate work with docking cart.

Machine main parameter:

|

Model |

YT202S |

|

Dimension(L*W*H) |

2788*1686*1375mm |

|

Weight |

1700kg |

|

PCB length width |

Max size:500*450mm(single PCB) 500*300mm(double PCB) Min size:50*50mm |

|

PCB thickness |

0.5~4.5mm |

|

Mounting height |

≤20mm |

|

Mounting precision |

±0.02mm |

|

No.of camera |

4 PCS |

|

Bottom vision camera recognition |

|

|

Vision alignment, Mark correction |

|

|

Components |

0201~40*40mm Tape reel packages and IC tray feeder etc. |

|

Optimum mounting speed |

80000CPH |

|

No. Of feeders station |

Double side docking cart slot:32PCS ,Tape reel packages:64pcs (Single side docking cart slot:16PCS ,Tape reel packages:32pcs)

|

|

No. Of head |

Double side:20pcs(single side:10pcs) |

|

X,Y Axis drive way |

High-end magnetic linear motor+Servo motor |

|

Feeding way |

Intelligent Double head Feeder |

The layout of Semi-auto SMT line:

Our company has more than 20 years of experience in SMT machines, we can provide you with complete line solutions.

Our clients:

ETON as the leading manufacturer of global photo electronic high speed pick and place machine, the products are exported more than 20 countries and regions, including India, Vietnam, Tunisia, Egypt, Turkey, Russia, Thailand, etc.Take India as an example,We have many big clients in India, Such as RK、SURYA、Fiem、Calcom、POLYCRB, etc. We have sold over a hundred machines to India.

Exhibition:

As a large company, our company participates in many domestic and foreign exhibitions every year, except during the epidemic:

Domestic Exhibition: Guangzhou international lighting Exhibition; Shanghai Munich Exhibition; Chongqing LED Light Exhibition, etc.

Overseas Exhibition: India Delhi Exhibition, India Mumbai Exhibition, Pakistan Exhibition, Egypt Exhibition, Tunisia Exhibition, Thailand Exhibition, etc.

Maintenance period 1 year

- One year warranty, during warranty, any parts that need to be repaired and replaced will be free

Software and hardware lifetime maintenance

- Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates

Visit customers regularly and gather information

- Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time

Provide the latest information about technology and equipment

- We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

- We have some official site in India as Mumbai and New Delhi, also have site in Egypt. Turkey that can provide service timely with our engineers.

- According to your needs. dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

FAQ:

1.Is the machines easy to operate?

Yes,of course.Our machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

2.How many hours does the machine can operate per day?

Machine can work whole day. But for longer using life, we suggest you to have 1 hour or 2 hours off per day.

3. How about the Training?

We provide the online remote training service, and we will offer you the operating video and manual for user’s repeatedly learning.

4.What are the terms of payment?

FOB Shenzhen is OK.