Description

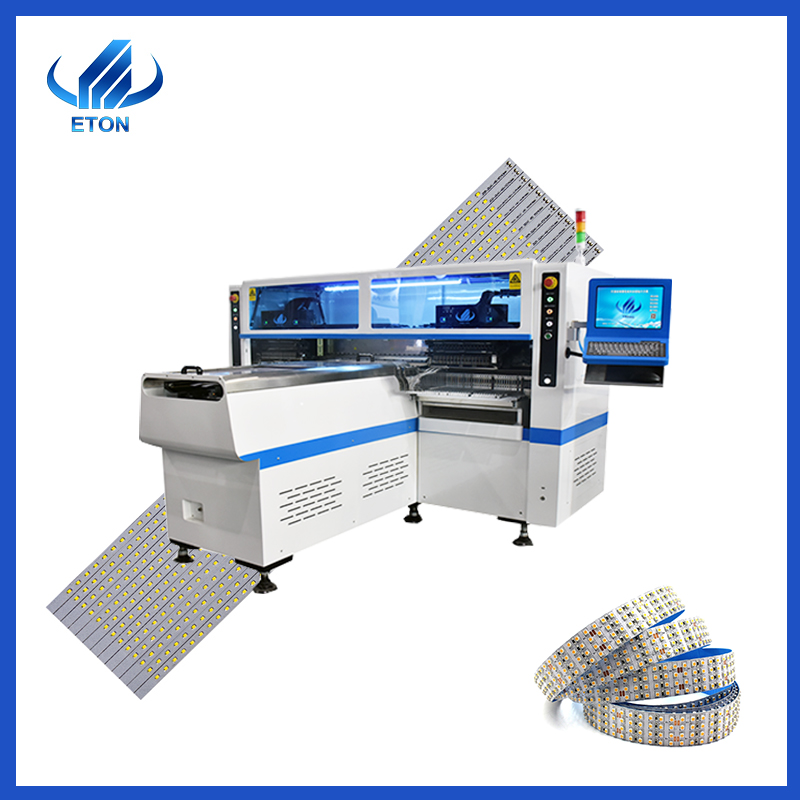

Description of Pick and Place Machine HT-E8S

The main function of SMT machine HT-E8S: Used for SMT production process to accurately mount components on PCB board fixed position.

The SMT machine uses the suction nozzle on the head to absorb various components from feeders and mount them on the PCB board.

SMT pick and place machine is the main equipment in SMT production process, which can not be replaced by other equipment.

SMT production process is the solder paste coating, component mounting, reflow welding, it is the most major process in the SMT production process. In order to get good mounting quality, SMT pick and place machine should have good mounting process in addition to good equipment.

Main features

Single module magnetic linear motor multifunctional pick and place machine

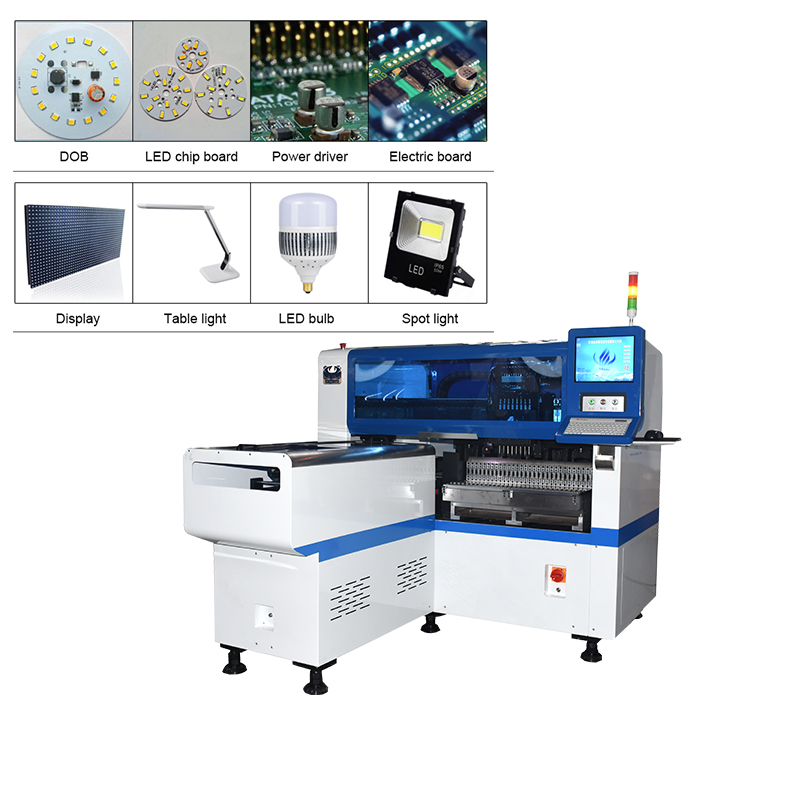

Mounting components:LED chip、capacitors、resistors、lens、IC、shaped

components、etc.

Component:Min.size 0402 Max. Height 15mm

Application: Power driver,electric board,lens,DOB bulb,linear bulb,household appliance etc.

28 feeder stations and 12 nozzles

Electronic feeder feeding system

Vision alignment flight identification, Mark correction

Auto-optimization after coordinates generated, etc

Product picture

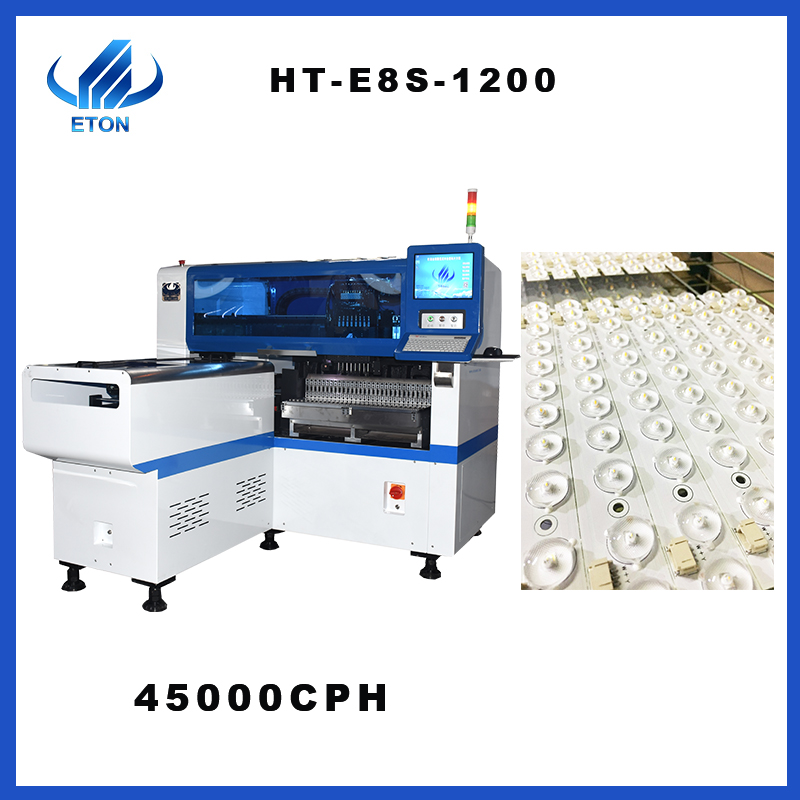

Main Technical Parameter

|

Dimension |

2550*1650*1550mm |

|

PCB Size |

Max: 1200*500mm Min: 100*100mm |

|

PCB Thickness |

0.5~5mm |

|

Mounting mode |

Group picking and separately placing、separately picking and separately placing |

|

Mounting precision |

±0.04mm |

|

Mounting height |

<15mm (Automatic changing) |

|

Mounting speed |

45000 CPH |

|

Components |

LED chip,resistors,capacitors,IC,shaped components etc. |

|

Components space |

0.2mm |

|

No.of feeders station |

28 PCS |

|

No.of head |

12 PCS |

|

Power |

380AC 50Hz |

|

Power consumption |

4 KW |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor and servo motor |

Machine main part:

Three main components: software, electrical and mechanical.

Machine parts and functions

Mainframe: The brain of a machine that collects feedback signals and processes them before issuing instructions

Electric box: all the circuit of the machine is integrated in the electric box. After external power connection, it controls the running process of the machine together with the host machine

Circuit board: Controls various parts of the machine

Servo motor: after the servo motor is energized, it turns positive and negative, and drives the screw rod to rotate by connecting the screw rod with the coupling, thus driving (mounting head, transportation platform) to do linear reciprocating motion. A servo motor controls a screw.

Linear motor: magnetic linear motor, through external electric connection to make the actuator generate a magnetic field, stator itself is a permanent magnet, moving stator through the interaction between magnetic poles to make the mount head reciprocating motion.

Magnetic grid ruler: non-contact scanning magnetic field, and the analog measurement value into absolute or incremental output signal, high detection accuracy, fast response speed, to a certain extent determines the accuracy of head mounting.

Linear guide rail: used to support and guide the moving part (mounting head, transport platform), according to the specified direction to do high precision reciprocating movement

Stepper motor: the track width is adjusted by adjusting the motor to drive the belt connecting screw, so as to be suitable for the installation of different circuit boards of customers. The transport motor drives the belt, which drives the circuit board.

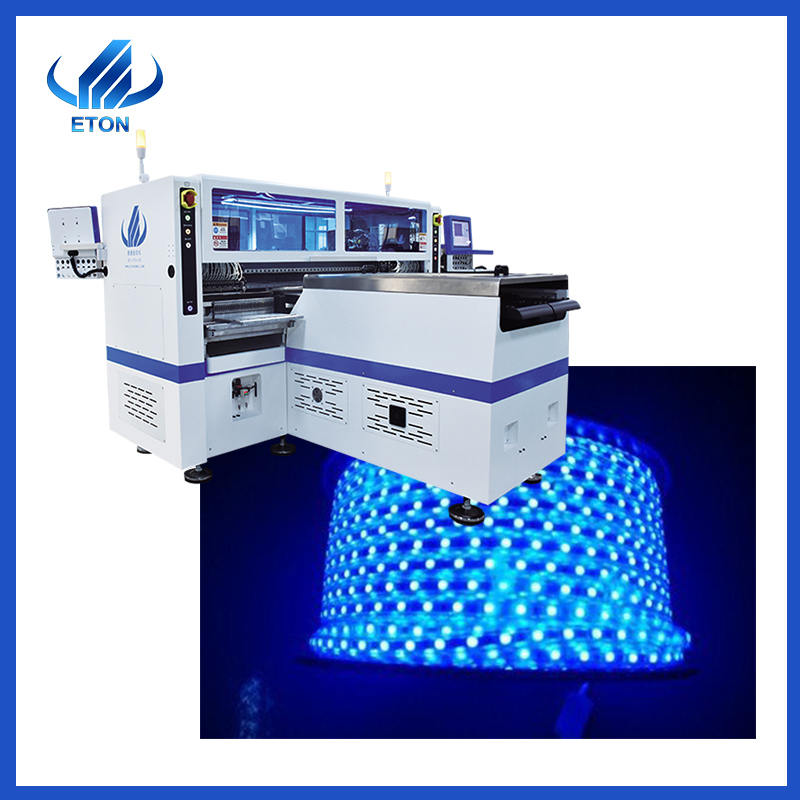

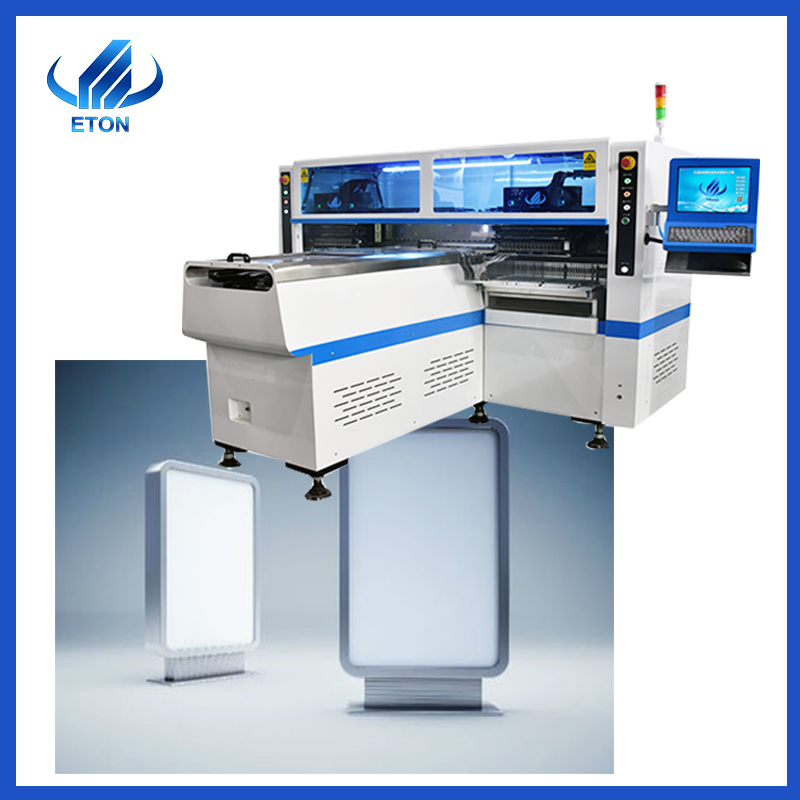

Application of HT-E8S:

Bulb light、DOB bulb、Display、Tube light、flexible strip light、Electric board、Power driver、LED chip board、Lens、Wall light、Street light etc.

The semi-automatic production line

Solder paste printing machine,conveyor, Pick and Place machine, reflow oven.

The full-automatic production line

PCB Loader, conveyor, transplanting machine, buffer frame, automatic printing machine, pick and place machine, belt transport guide rail, reflow oven, PCB Un-loader.

Our advantages:

Rich experience in SMT Industry Line. ETON set up more than 10 years, we are leading manufacturer of SMT machine in China.

Our machines are of better quality, more accurate and faster to mount. We also have our own exclusive patented technology such as dual motor electronic Feeder feeding system, flight identification visual alignment, group picking and group placing and so on.

Certification:

We got 9 invention patents, 112 practical patents,12 software patents.

We are high-tech enterprise with CE,SIRA,CCC ,ISO awarded as “Well-know brand” and many technology patents, and have rich experience(more than 8 years) in LED light production line program.

Our Exhibitions:

ETON is a very strong and powerful company. We attend many exhibitions every year.

Not only in China, India Delhi, Indian Mumbai, Pakistan Karachi, Turkey Istanbul, Egypt Cairo, Russia Moscow, Vietnam Hanoi etc.

We occurred 85% percent in China LED lighting markets, but also send machines to India, Korea, UK, Russia, Egypt, Turkey, Vietnam, Japan, Australia, Poland, etc more than 20 countries.

Working with ETON is guaranteed, let’s light up your business!

Service

- We have 1 YEAR Maintenance period

- We will 24 hours 7 days online Answer questions

- We Provide personal customization to satisfy your personalized production needs.

- We have Overseas engineers to teach equipment operation one to one.

FAQ:

Q: What’s your delivery time?

A: Usually 30 days after deposit, if we have inventory, the time can be brought forward.

Q: Is there any quality guarantee?

A: We stick to quality first, client-oriented, Continuous improvement!

Q: Is your software interface in English?

A: English interface and Chinese interface are both available.

Q:What are your advantages?

A: Our company stick to five level management policy: sincere business, focus on R&D, manufacturing intentions, considerate service, customer trust.

Q: If my order is very urgent, how long you can proceed?

A: We have helped many clients with their urgent demand. If your order is urgent, please contact with our specialist and we will help you to apply special support.