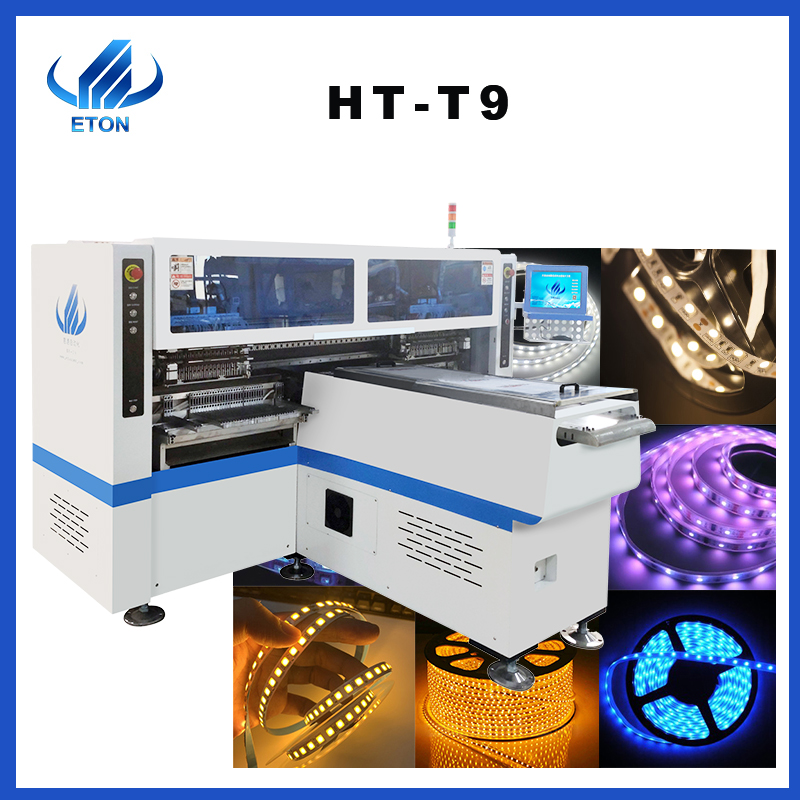

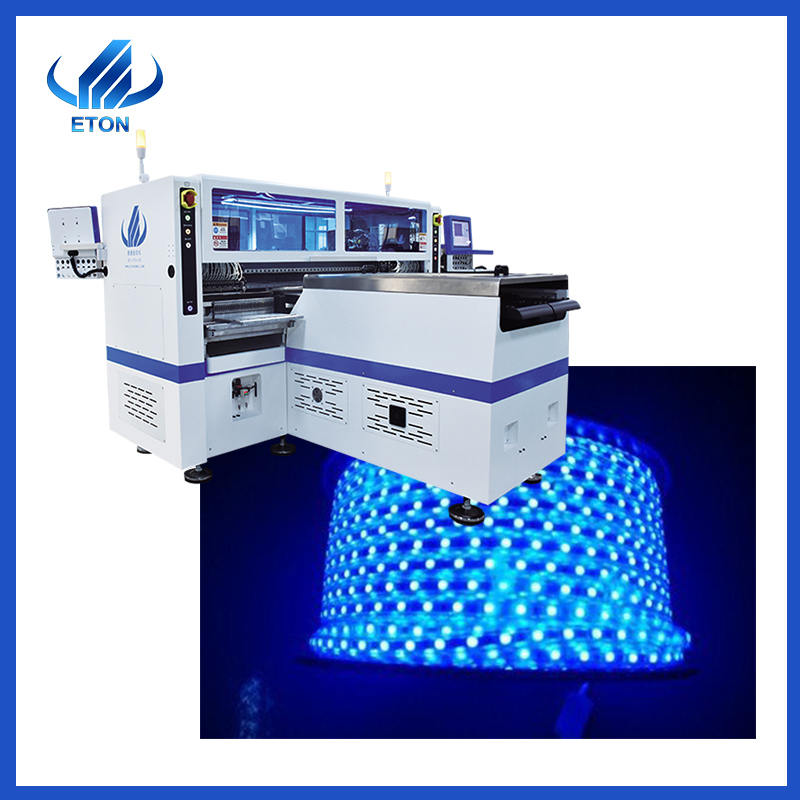

- Single module magnetic linear motor multifunctional pick and place machine.

- Mounting components:LED chip, capacitors, resistors, lens, IC, shaped components, etc.

- Component: Min. Size 0402, Max. Height 15mm.

- Application: Power driver, electric board, lens, DOB bulb, linear bulb, household appliance etc.

Multifunctional LED PCB assembly mounter

Description

Product description

Single module magnetic linear motor mounter machine E8S-600 use group picking and separately placing, separately picking and separately placing mounting mode with 12 pcs of head 2 sets of imported digital camera

- Single module magnetic linear motor multifunctional pick and place machine.

- Mounting components:LED chip, capacitors, resistors, lens, IC, shaped components, etc.

- Component: Min. Size 0402, Max. Height 15mm.

- Application: Power driver, electric board, lens, DOB bulb, linear bulb, household appliance etc.

Exclusive Patented Technology:

- Electronic feeder feeding system.

- Vision alignment flight identification, Mark correction.

- Non- stop material re-loading function.

- Auto-optimization after coordinates generated, etc.

Machine parameter

|

Model |

HT-E8S-600 |

|

Dimension |

1550mm*1650mm*1550mm |

|

Total weight |

1500kg |

|

PCB length width |

Max:600*500mm Min:100*100mm |

|

PCB thickness |

0.5-5mm |

|

PCB clamping |

Adjustable pressure pneumatic |

|

Mounting mode |

Group picking and separately placing, Separately picking and separately placing |

|

Mounting precision |

±0.04mm |

|

Mounting speed |

45000CPH |

|

No. of feeders station |

28PCS single module |

|

No. of head |

12 PCS single module |

Our products had exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:

SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

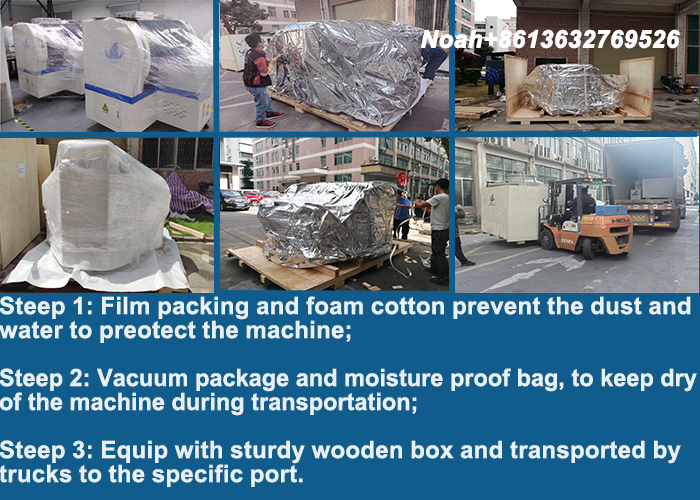

Step 1: Wrap with stretch film to prevent the equipment from.

Step 2: Vacuum paper packaging and moisture-proof bag, so that the machine can be kept dry during transportation to prevent moisture.

Step 3: Use straps and triangular wood to fix the machine to prevent damage to the machine during transportation.

Step 4: Each exported machine will be equipped with sturdy export wooden boxes, to ensure that the delivered product is good.

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

-

- How long can the delivery date take?

- If have stock the delivery date is about 20 days, others is according to the actual situation.

- What is your usual payment term?

- Our usual payment term is T/T, that requires to pay 30% in advance, and pay the balance off before the delivery of the goods.

- Can you accept D/P or D/A as the payment term?

- For our regular payment terms, we usually use T/T.

- How can I contact you to buy the goods in an efficient way?

- Making enquiry of the products you want on the trading platform of Alibaba, Tradelink, foreign trade Express, or contact us with the social software as Whatsapp, Skype, etc.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com