- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, wide component range;

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10mm;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum speed reach 45000 CPH;

- High-speed precision head flight vision camera capture the image of placement accordingly, improve placement performance;

- The placement head adopt independent vacuum detection, improve placement performance;

- Software AI intelligent learning function and automatic optimization function.

New 10 heads surface mounting machine

Description

- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, wide component range;

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10mm;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum speed reach 45000 CPH;

- Brand new self-developed high precision placement head;

- High-speed precision head flight vision camera capture the image of placement accordingly, improve placement performance;

- The placement head adopt independent vacuum detection, improve placement performance;

- Off-line programming, save time of changeover cycle;

- Software AI intelligent learning function and automatic optimization function.

|

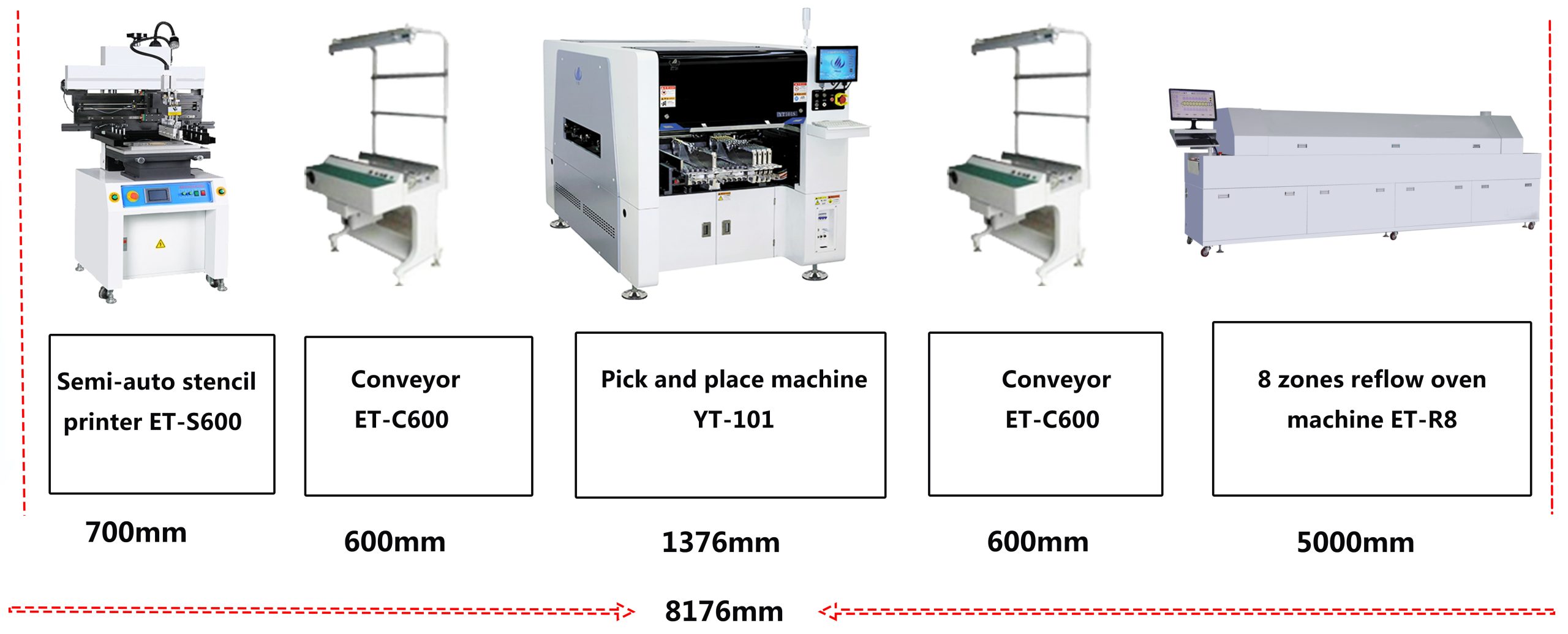

Model |

YT-101 |

|

PCB size |

Max size: 500*350 mm Min size: 50*50 mm |

|

PCB thickness |

0.5-4.5 mm |

|

PCB clamping |

Cylinder clamping, track width adjustable |

|

Software |

R&D independently |

|

Production management MES system |

Customized (Option) |

|

Off-line programming |

Available |

|

Camera |

Head flight vision recognition component Vision alignment + Mark correction |

|

Repeat precision |

±0.02 mm |

|

Mounting height |

≦20 mm |

|

Optimal speed |

45000 CPH |

|

Position mode |

Optical |

|

Component range |

Min 0201~10mm packages and IC etc. |

|

Position mode |

Optical |

|

No.of heads |

10 pcs |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor + Servo motor |

|

Feeding way |

Intelligent double head feeder |

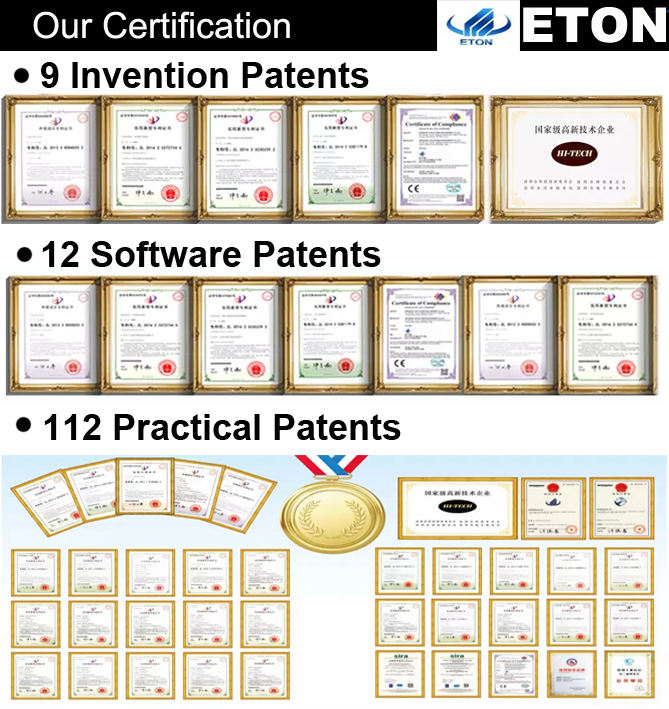

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA, etc.

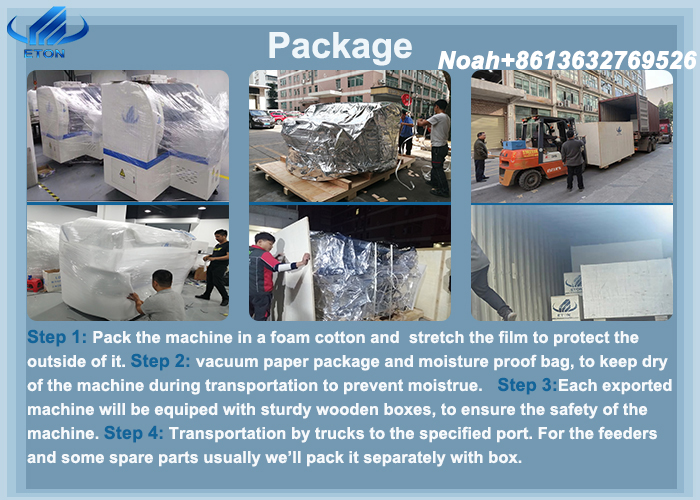

Keep a good quality of the machine when during transportation till the destination of our clients which is an imperative aspect for one of a suitable service for our clients to buy our machine, so making sure of a qualified and sturdy packing is a key mission for us, here are the specified steps for your reference:

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

- What is your the payment term?

- For our regular payment terms, we usually use T/T.

- Can you accept CFI as the quoted price?

- We usually accept EXW as the quoted price.

- How is your services?

- We ensure our clients to enjoy an optimal experience of the service of communication and relevant needs of the machine for installation, maintenance and free up- grade.

- What is your actual speed of your products?

- For the actual speed of the machine which is constrained by many factors, that related to the number of the components, the time to send PCB board and receive the board, etc. And is decide for the actual products and needs.

- What is your merits of the machine to others production?

- Initially, we have a strong R&D department for studying our productions, and our clients can enjoy free up-grade of the machine to get latest information about technology and equipment, besides, we have a 52000 square meters industrial park to serve the production, assembly, and commissioning of our machines.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com