Features

- It adopts imported high-speed air-carrying motor direct drive for thermal cycle, low noise, low vibration and high thermal cycle efficiency.

- It adopts Panasonic PLC industrial control products to control the upper and lower computer, which has first-class stability.

- It has a delay switch protection function to prevent the transmission components from deforming due to uneven cooling.

- It has a power-off protection function to ensure the normal output of the PCB without damage after power-off.

- With over-temperature sound and light alarm and emergency braking system.

- All zones are heated separately up and down, independent hot air circulation, independent temperature control, and the temperature control accuracy is ±1℃.

- Modular heating structure can effectively prevent the influence of airflow in the temperature range, ensure that the components are evenly heated, and the lateral temperature deviation is <±2℃.

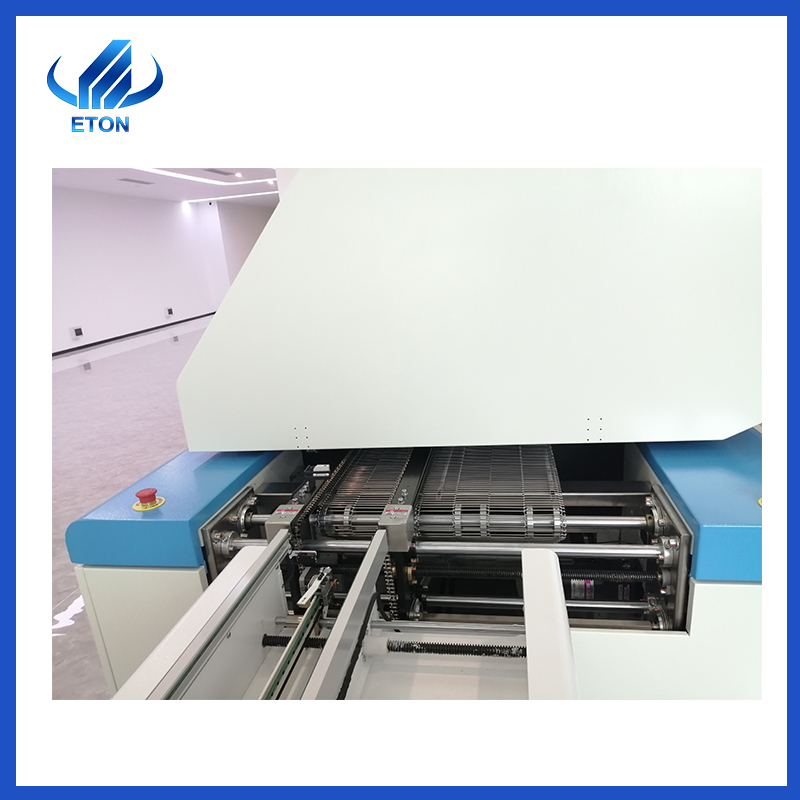

- The upper furnace body is opened by pneumatic jacking, which is safe ,reliable and convenient for furnace cleaning.

- The heat source of the special durable nickel heating wire, abundant power, rapid heating, less than 20 minutes from room temperature to constant temperature.

- Simplified and traditional Chinese MMI operation interface and artificial intelligence software control greatly facilitate the user’s use.

- It has a complete online temperature test curve and analysis, storage, recall and printing functions.

- Dedicated temperature acquisition module, high accuracy and fast speed, with cold junction compensation function.

- Temperature collection adopts RS-485 interface, which is convenient for remote device temperature monitoring.

- With timing automatic shutdown function.

- Host computer control, computer can be cut off, independent control, computer operation, convenient man-machine dialogue, clear interface, intuitive image, can switch between Chinese and English at any time, and various parameter settings realize accurate and fast numerical input.

- Using PLC control, the temperature control is stable and accurate, and the temperature of each zone is individually controlled.

- The motor is imported, high-quality,and high-temperature-resistant, with good structure and good heat dissipation, to ensure its service life and reliability. The direct connection mode connects the wind wheel with a speed of up to 2800rpm to provide sufficient hot air flow.

Technical parameter

|

Product model

|

ET-R8

|

|

Heating system

|

|

NO. of heating zone

|

Upper 8 hot air heating, lower 8 hot air heating

|

|

Length of heating zone

|

3000mm

|

|

heating method

|

Full hot air

|

|

Delivery system

|

|

PCB maximum width

|

400mm mesh belt, no lead rail

|

|

Transport direction

|

left-right,right to left(option)

|

|

Conveyor belt height

|

Mesh belt 880±20mm

|

|

Delivery method

|

Mesh belt drive + rail (optional)

|

|

Conveyor speed

|

0-2000mm/min

|

|

Control System

|

|

power

|

380V 50/60Hz Three-phase five-wire AC:380V 50Hz

|

|

Starting power

|

28KW

|

|

Working power

|

7KW

|

|

Heating time

|

Around 15 mins

|

|

Temperature control range

|

Room temperature~350℃

|

|

Temperature control method

|

PID control + SSR drive

|

|

Temperature control accuracy

|

±1℃

|

|

Abnormal alarm

|

Abnormal temperature alarm

|

|

Machine dimensions(L*W*H)

|

4600mm*1000mm*1400mm

|

|

Machine weight

|

1300kg

|

why use reflow technology?

Due to the continuous miniaturization of PCB board of electronic products, chip components appear, and the traditional welding method can not meet the needs. At first, the reflow soldering process was only used in the assembly of hybrid integrated circuit boards. Most of the components assembled and welded were chip capacitors, chip inductors, Mount Transistors and diodes. With the development of the whole SMT technology and the emergence of a variety of SMC and SMD, reflow soldering technology and equipment as a part of SMT technology have also been developed accordingly, and its application is becoming more and more extensive, which has been applied in almost all electronic products.

FAQ

Q: Are you a trade company or a manufacturer?

We are an professional manufacturer specialized in Screen Printer,SMT Machine, Pick and Place Machine, Reflow Oven, SMT Production line and other SMT Products.

Q: What is your delivery date?

The delivery date is about 20 days upon the full payment.

Q: What is your payment terms?

A:100% payment before delivery or 50% deposit in advance and the rest before shipment.