- Independent two operation systems, 2 computers, and two modules, so you can

produce 2 different products at the same time - There is 4 high-end magnetic linear motor for each module, more smooth and

faster than servo motor - Two electronic conveyors for each module

- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 4 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

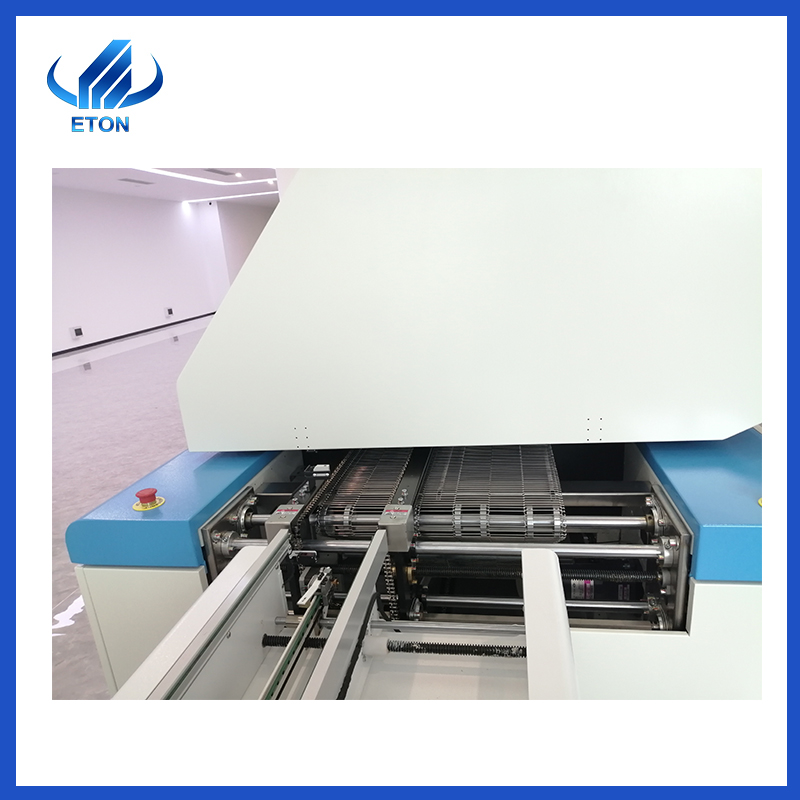

Reflow Oven of molten solder paste

Description

Reflow Oven characteristics

Reflow Oven technology is no stranger in the field of electronic manufacturing. The components on various boards and cards used in our computers are welded to the circuit board through this process. There is a heating circuit inside this equipment, which heats the air or nitrogen to a sufficiently high temperature and blows it to the circuit board with the components pasted, so that the solder on both sides of the components melts and bonds with the motherboard. The advantage of this process is that the temperature is easy to control, oxidation can be avoided in the welding process, and the manufacturing cost is easier to control.

Development history of reflow soldering

According to the continuous improvement of heat transfer efficiency and welding reliability of products, reflow welding can be roughly divided into five development stages.

Fold first generation

Hot plate conduction reflow soldering equipment: the heat transfer efficiency is the slowest, 5-30 w/m2k (the heating efficiency of different materials is different), with shadow effect.

Fold second generation

Infrared thermal radiation reflow soldering equipment: the heat transfer efficiency is slow, 5-30w/m2k (the infrared radiation efficiency of different materials is different), there is a shadow effect, and the color of components has a great impact on the heat absorption.

Fold the third generation

Hot air reflow soldering equipment: high heat transfer efficiency, 10-50 w/m2k, no shadow effect, color has no effect on heat absorption.

FAQ

Q:What is the delivery date?

We will deliver the goods after 30 days’ deposit.

Q:Is electrical control developed independently?

Yes, the electrical control is by ourselves and have exclusive patent technology.

Q:Are you a manufacturer or trading company?

manufacturer. We have our own industrial park