- Independent two operation systems, 2 computers, and two modules, so you can

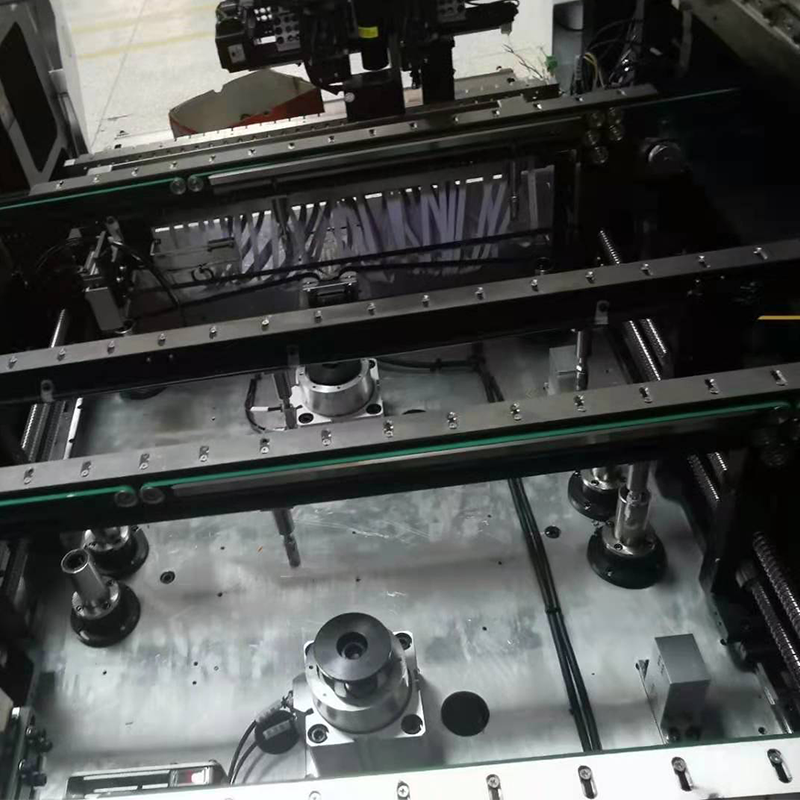

produce 2 different products at the same time - There is 4 high-end magnetic linear motor for each module, more smooth and

faster than servo motor - Two electronic conveyors for each module

- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 4 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

RT-2 Multifunction Pick And Place Machine

Description

|

Model |

RT-2 |

|

Dimension(MM) |

1195(L)* 1930(W)* 1750(H) |

|

Mass/weight |

250KG |

|

Board Dimension |

Max:400*350mm Min:50*50mm |

|

Power |

AC 380V 50Hz |

|

Mounting Precision |

±0.04 MM |

|

Power Consumption |

8KW |

|

Mounting Speed |

30000-35000CPH |

|

Applicable Parts |

Chip 0402 ,LED resistor ,capacitors,shaped components.etc. |

|

Alignment camera No.: |

High definition 2pcs camera (Flying Vision camera+ 1 pc Mark camera) |

|

Transmission Speed |

>1500 mm/ Sec |

|

Mount mode |

Single module |

|

No. of feeder station |

64pcs |

|

No. of nozzle heads |

20pcs |

|

Feeding way |

Electric feeder with double motor |

Exclusive patented technology :

-

- Electronic feeder feeding system.

- Vision alignment flight identification, Mark correction.

- Auto-optimization after coordinates generated ,etc.

Patent number:

ZL 2011 2 0237740.9\ ZL 20 11 2 0334606.0\

ZL 2012 2 0178869.1\ ZL 2012 2 0415505.0\

ZL 2012 2 0415044.7\ ZL 2012 2 0415356.8\

ZL 2012 2 0415061.0

Function Introduction:

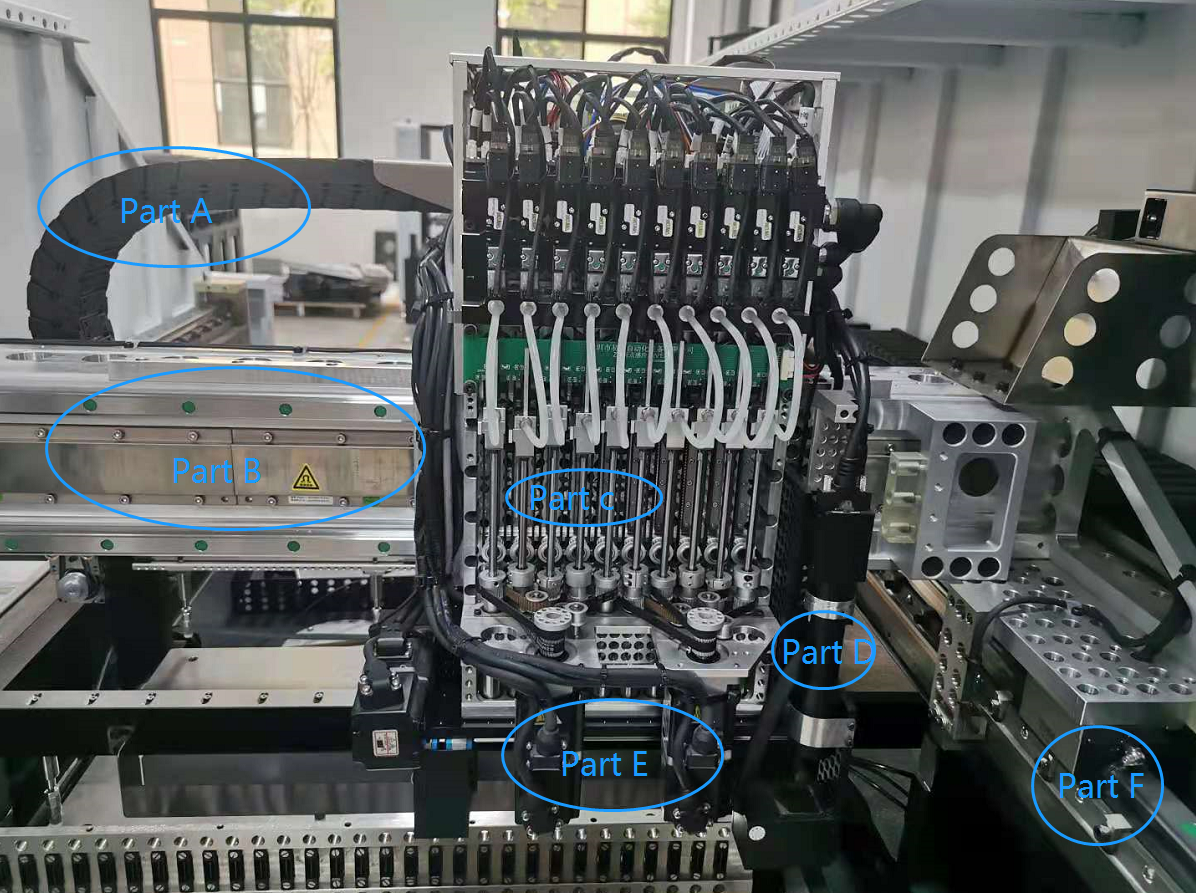

Function of each part:

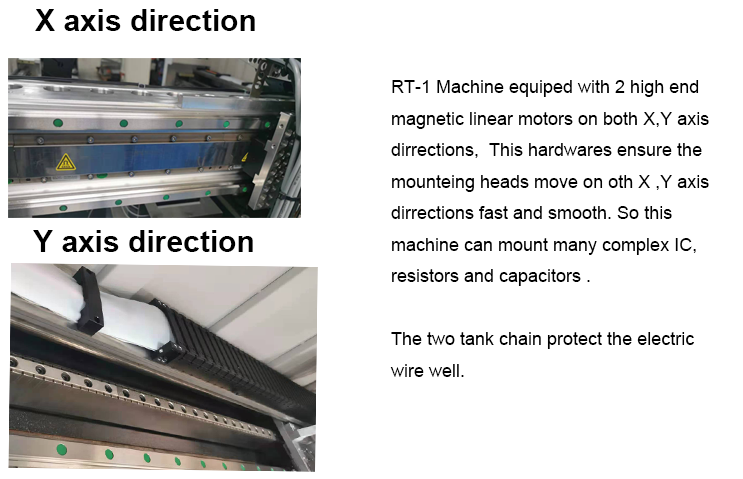

Part A: Its Tank chain, protect the wires and lines free of abrasion.

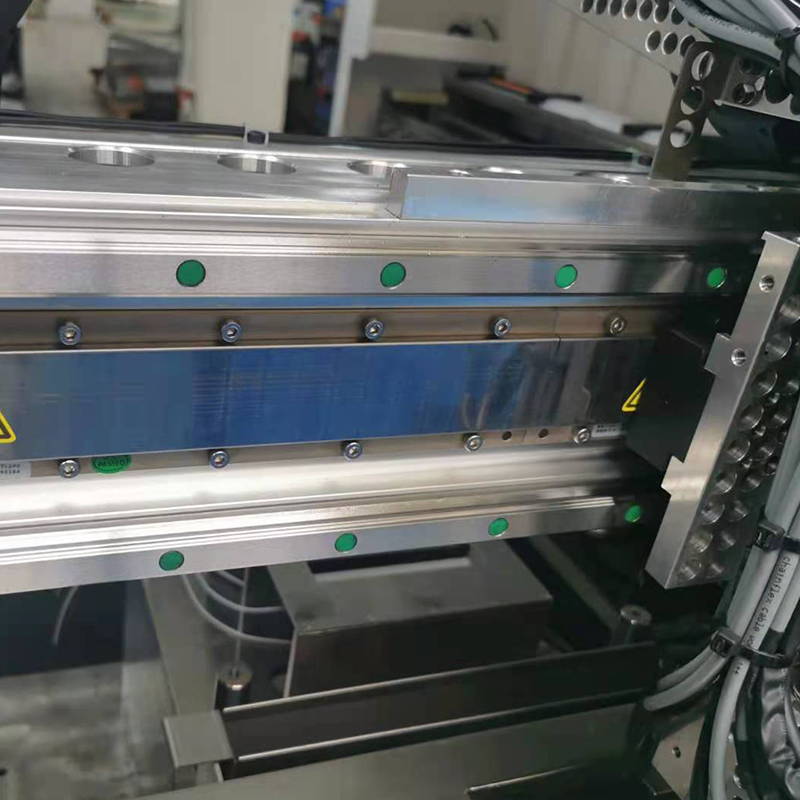

Part B: High-end Magnetic linear motor provides power for the mounting heads

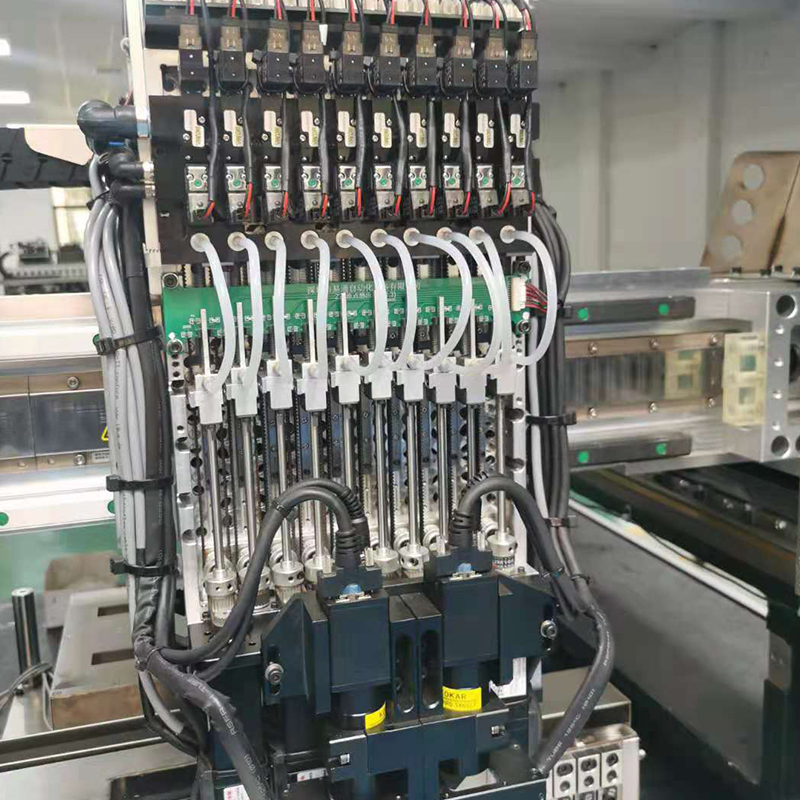

Part C: Vacuum nozzle tube, one end connected with vacuum air hose and another

connect with nozzles

Part D: High-resolution camera for accurate vision alignment correction

Part E: Two motors to provide power for nozzles tube angle while mounting

Part F: Same as part B.

-

-

RT-1 is equipped with 2 sets of magnetic linear motor, It’s more convenient to mount some

complex components:LED, capacitors,resistors,IC,shaped components, etc.

-

The capacity of RT-1 is reach 30000~35000CPH.

-

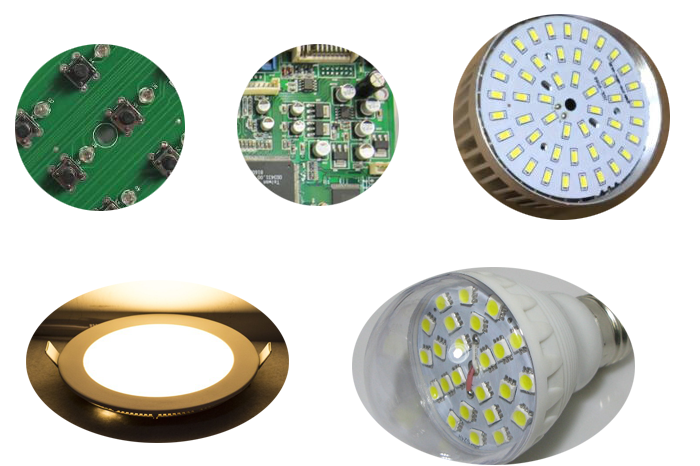

Production: DOB, home appliance control boards, power drivers, LED down-lights, LED

bulb lights, LED panel lights, etc.

-

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.