Features:

- The governor motor drive scraper, combining precision linear guide, ensure the printing precision;

- Printing scraper can rotate 45 degrees of fixed upwards, printing plate and scraper cleaning and replacement;

- The scraper holder can adjust forward and backward, to select the suitable printing position;

- Combined printing platen, has a fixed groove and positioning PIN, easy installation and adjustment, it is used for single and double panel printing;

- Steel bar-mesh mobile school edition way, combined with the printing machine (PCB) XYZ calibration adjustment, convenient and quick.

- Can be set unidirectional and bidirectional multiple printing methods

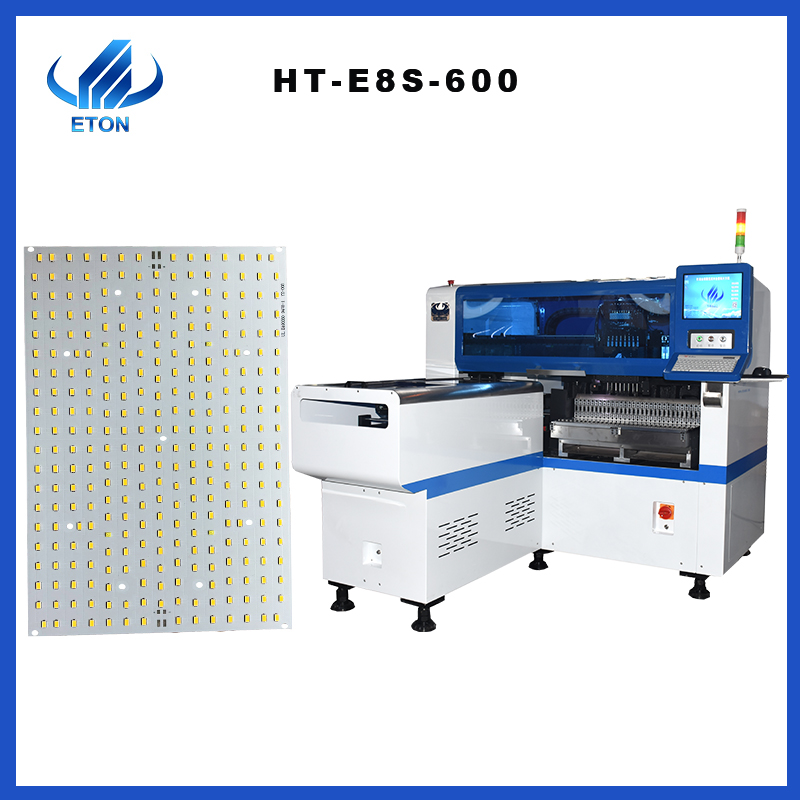

Technical parameter

|

Model

|

ET-S600

|

|

Dimensions

|

1400*800*1680mm

|

|

Platform size

|

650×320mm

|

|

PCB size

|

600×300mm

|

|

Template size

|

550×830mm

|

|

Printing speed

|

0-8000mm/min

|

|

PCB thickness

|

0-50mm

|

|

PCB fine tuning range

|

Front/side±10mm

|

|

Power supply

|

1PAC 220V 50/60HZ

|

|

Platform height

|

850±20mm

|

|

Repeatability precision

|

±0.01mm

|

|

Positioning mode

|

Outside/Reference hole

|

|

Weight

|

Approx.200Kg

|

Operation steps of semi-automatic printer

Preparation before printing: take the steel mesh with the same model and specification as PCB, take the template as a example, clean the steel mesh and printing table with plate washing water, move the steel mesh to make the steel mesh completely consistent with PCB, fix the printing operation, take the thawing solder paste, stir it with a stirring knife for 3-5 minutes, evenly wipe it to 1-2cm of the steel mesh, and the width can completely cover the PCB. After printing, check whether there is missing printing, complete the operation after printing, clean the tools and turn off the power supply.

Maintenance instructions for semi-automatic printer

Daily maintenance:

Check whether the sensor works normally

Check whether the scraper is installed and leveled correctly

Check whether the operation keys are normal

Weekly maintenance:

Clean and lubricate the bearings of each department

Monthly maintenance:

Clean the drive case

Check the tightening of screws at all parts

Check whether there is electric leakage in the electrical part

FAQ

Q:What is the delivery date?

We will deliver the goods after 30 days’ deposit.

Q:Is electrical control developed independently?

Yes, the electrical control is by ourselves and have exclusive patent technology.

Q:Are you a manufacturer or trading company?

we are manufacturer. We have our own industrial park