Description

Machine introduction:

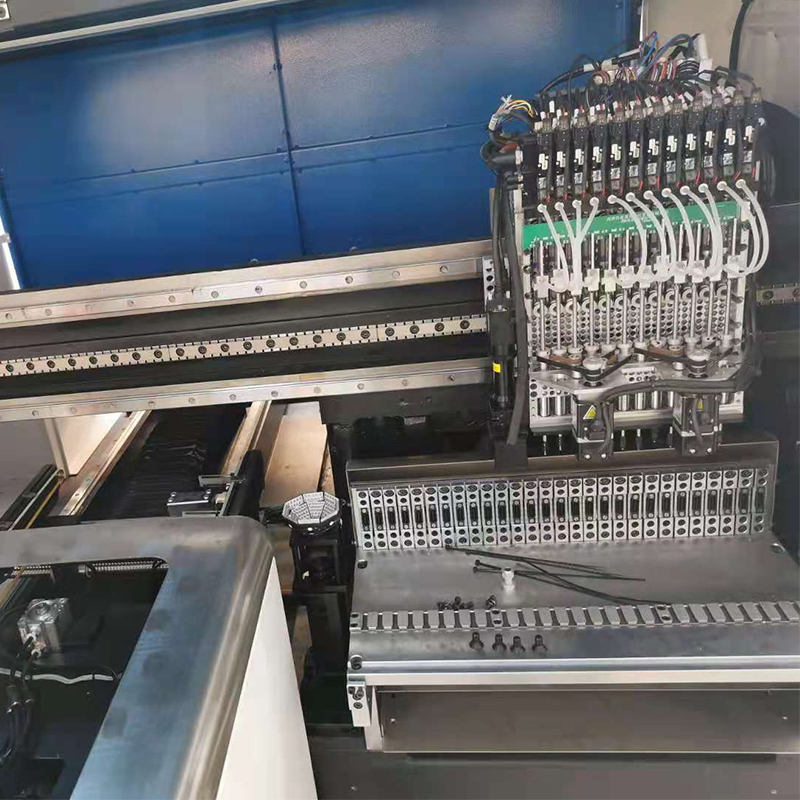

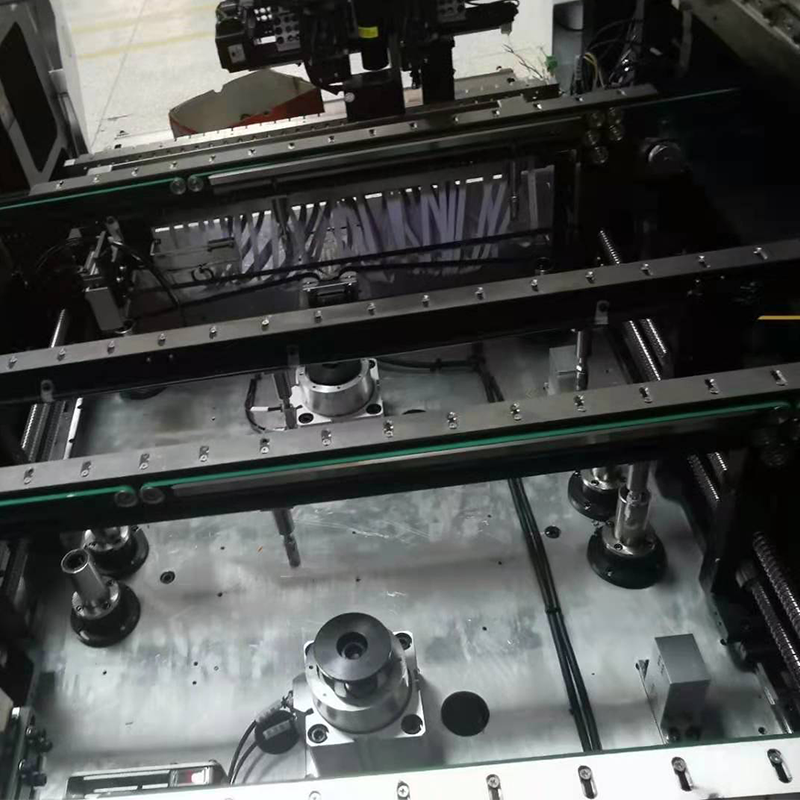

1.HT-E8S-1200: Single module magnetic linear motor multifunctional pick and place machine.

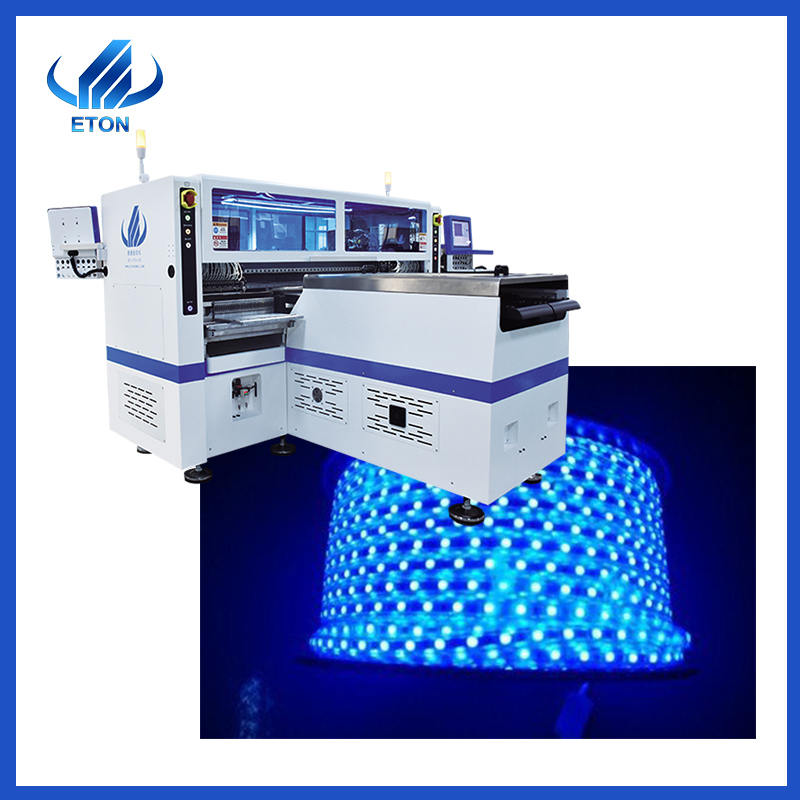

2.suitable for many kinds of production, such as LED lighting, DOB, display, electric board, power driver, household appliance, lens and so on. The LED lighting includes all kinds of types, such as LED bulb, LED tube, flexible strip ( 0.5 M, 1 M, 1.2 M etc ), street light, down light, spot light, table light, panel light, ceiling light and so on.

3.Components:LED chips, capacitors, resistors, inductance, IC, lens, shaped components etc. The size of electronic components is min size 0402, the max height can reach 15 mm.

4.12 Heads, optimum mounting speed reached 45000CPH.

5.Exclusive patented technology:

Electronic feeder feeding system,Non-stop material re-loading function, Auto-optimization after coordinates generated, etc.

Machine technical parameter:

|

Model |

HT-E8S-1200 |

|

Dimension(L*W*H) |

2550*1650*1550mm |

|

Weight |

1700kg |

|

PCB length width |

Max:1200*500mm;Min:100*100mm |

|

PCB thickness |

0.5~5mm |

|

Mounting mode |

Group picking and separately placing, separately picking and separately placing |

|

No.of camera |

2 sets of imported camera |

|

Vision for the flight identification, Mark correction |

|

|

Mounting height |

<15mm(automatic changing) |

|

Mounting speed |

45000cph |

|

No. Of feeders station |

28 PCS single module |

|

No. Of head |

12 PCS Single module |

|

Mounting precision |

±0.04mm |

|

Components space |

0.2mm |

|

Conveyor transmission |

Max length:1200mm |

|

Power |

380AC 50 HZ |

|

Power consumption |

4KW |

|

X,Y,Z Axis drive way |

High-end magnetic linear motor and servo motor |

|

Feeding way |

Electric feeder with double motor |

|

Components |

LED chip, capacitors, resistors, IC, shaped components, etc. |

HT-E8S-1200 Pick and place machine Application:

HT-E8S-1200 pick and place machine has a particularly wide rang of applications.

Multifunctional module HT-E8S SMT Mounter suitable for mounting many kind of led lighting, such as led bulb, panel, DOB, strip light, tube, display, down-light, street light, etc.

One machine can meet all you need.

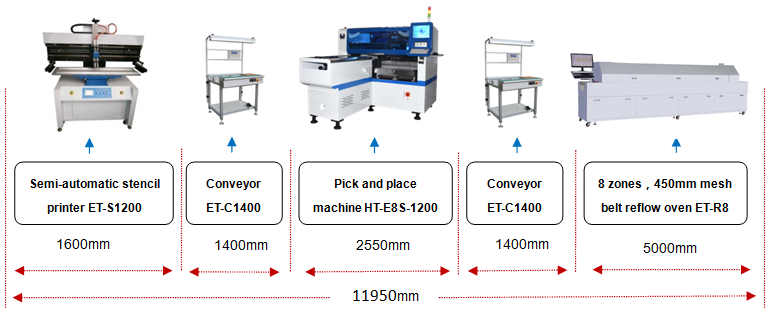

HT-E8S-1200 SMT line solution:

Solder paste printer Machine(Solder paste printing): The solder paste or patch glue is leaked onto the pads of the PCB board to prepare for the next step of soldering the components.

Conveyor : Transmission the PCB boardat the same time, It is used for connection between SMT production lines .

Pick and place machine HT-E8S-1200: Accurately mount surface mount components to fixed positions on the PCB board.

Reflow oven:Melt the solder paste or die glue to firmly bond the components to the driver board.

Our advantages:

1.We have a high-speed placement machine with 500,000 CPH, which has broken the world record.

2.My products are exported to more than 20 foreign countries and regions, occupying 85% of the LED customer market.

3.All software of our machine is independently developed by the company, which can provide customers with free upgrades and updates.

4.We have our own industrial park, covering an area of 50,000 square meters, which is specially used to manufacture and produce various SMTequipment.

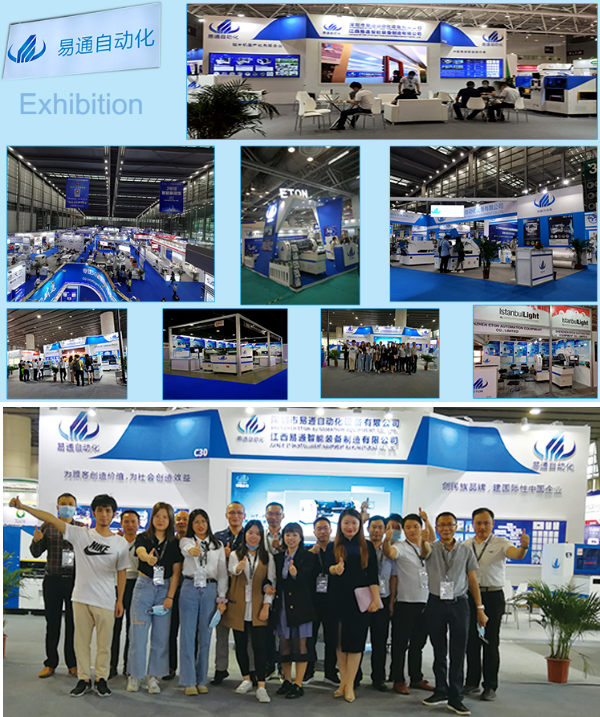

Company profile:

ETON Automation Equipment Co.,Ltd was established in 2011.It is a manufacturing and process solution provider focusing on R&D , production , sales and services of SMT high-speed pick and place machines and SMT peripheral automatic equipment.We have decades of R&D experience and mature technology in this field.We have an industrial park covering an area of 50,000 square meters in jiangxi, which is dedicated to the production of machine to make machine.Our products exported to over 20 countries and regions. We have been working with numerous big companies in India, Turkey, Pakistan,Egypt etc.

Exhibition:

Our company participates in exhibitions domestic and foreign exhibitions every year (except during the epidemic period)such as:

Overseas: India Delhi Exhibition, India Mumbai Exhibition, Pakistan Exhibition, Egypt Exhibition, Tunisia Exhibition, Thailand

Exhibition, etc.;

Domestic: Guangzhou Guangya Exhibition; Shanghai Munich Exhibition; Chongqing LED Light.

FAQ:

1.Can you support whole SMT line?

Yes, we can provide whole line solution if you want. We are very professional on SMT field.

2.What is the difference of automatic line and semi automatic line ?

The big difference of auto line and semi-auto line is the price and the labor. Automatic line required higher cost but save much cost of labor. Usually one operator is enough. But semi automatic line need at least 2 workers.

3.How about the After-sale Service?

We provide one year warranty, during the warranty period, if any wrong, we will send the accessories free of charge.