Description

Machine main features

- No cleaning solution required

- Low noise

- High efficiency and energy saving

- 24 suction nozzles cleaned at a time

Principle and configuration features of cleaning machine:

- The suction nozzle cleaning machine adopts a unique mechanical design. It uses fluid mechanics to break the water and produce a very small high-pressure water mist.

- It forms a powerful kinetic energy jet on the suction nozzle at the sonic speed (v = 360m / s), forms a continuous energy field above the suction nozzle to be cleaned, and thoroughly smashes the dirt on the surface and inside (since the suction nozzle is placed independently, it will not damage the suction nozzle during the cleaning process). After cleaning, it will not damage the suction nozzle During the process, the cleaning solution (deionized water or distilled water) is automatically discharged directly.

- High quality touch screen human-machine interface, PLC control;

- The pneumatic part uses imported SMC pneumatic components from Japan, which ensures stable and efficient working efficiency;

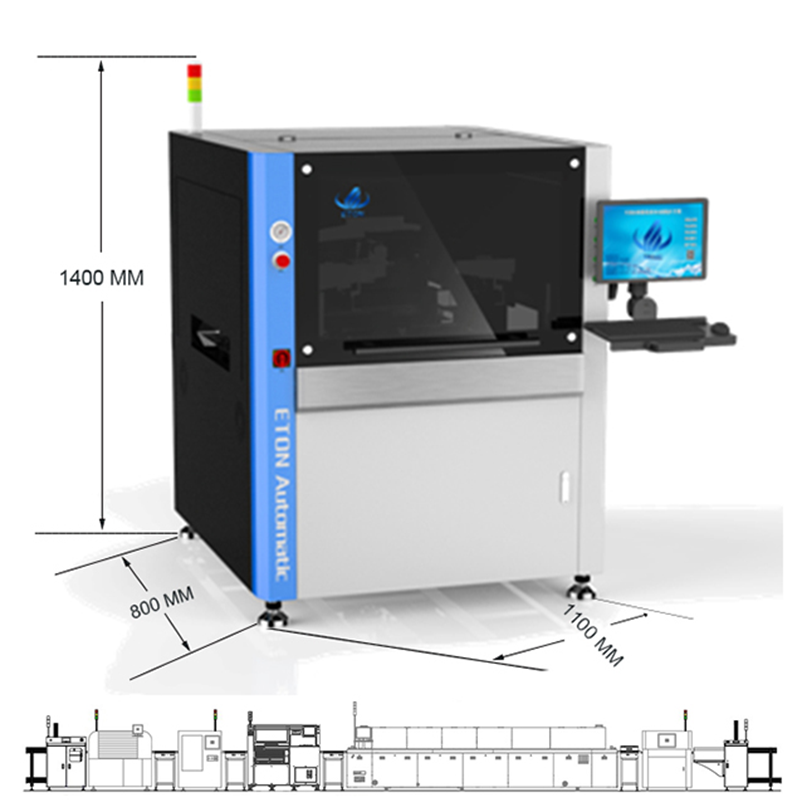

Machine main parameter

|

pressure |

pressure |

compressed air |

|

Intake pressure setting |

0.5~0.55MPa |

|

|

Injection pressure setting |

0.35~0.38MPa |

|

|

Nozzle injection pressure |

≤0.4MPa |

|

|

Tube |

Intake manifold |

¢12tube |

|

Drain tank water pipe |

¢8tube |

|

|

Cleaning liquid |

Cleaning liquid |

Industrial deionized water |

|

Liquid consumption |

≤300cc/h(5cc/min) |

|

|

Capacity of water storage tank |

1200cc |

|

|

Power Supply |

Power Supply |

AC220~240V |

|

Plug |

3-Pin |

|

|

Consumption of electricity |

≤0.1Kw |

|

|

Environment |

Working environment temperature |

-5℃~ (But not frozen.) |

|

Liquid temperature |

0℃~ (But not frozen.) |

|

|

Working environment humidity |

10~60%RH |

|

|

Environmental humidity of equipment |

10~60%RH |

|

|

dust |

0.1mg/m³(No conductive dust) |

|

|

Corrosive gas |

Not allow |

Economic benefits:

Reduce the purchase cost of suction nozzle; after using sme-24 cleaning machine, it can solve the problem of too dirty suction nozzle and scrap, so as to extend the service life.

Reduce unnecessary labor; because the machine adopts automatic cleaning, no special person is responsible for it, and the whole process is automatically completed by the machine.

It can effectively reduce the defective rate of products and improve the productivity of SMT. In the production process, a large part of it is caused by the uneven dirt on the surface of the suction nozzle and the dirt in the inner cavity, resulting in the throwing or mounting displacement, resulting in poor subsequent welding. After using the cleaning machine, the suction nozzle can always be protected in a new state, greatly improving the production efficiency.

Certificates

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA, etc.

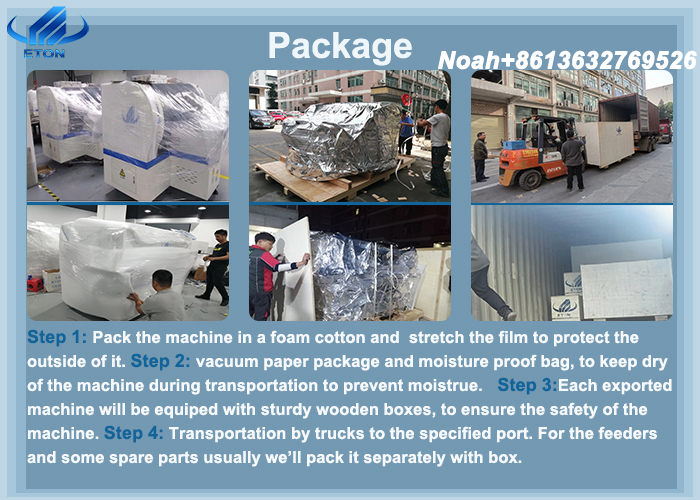

Packages

Our package step is follow the blowing:

STEP 1: Film packaging to prevent the dust and water;

STEP 2: Packing in a foam cotton stretch a film to protect the outside of the machine;

STEP 3: Vacuum paper package and moisture proof bag, to keep dry during the transportation;

STEP 4: Equip with sturdy wooden boxes to ensure the safety of the machine, then transportation by trucks to the specified port.

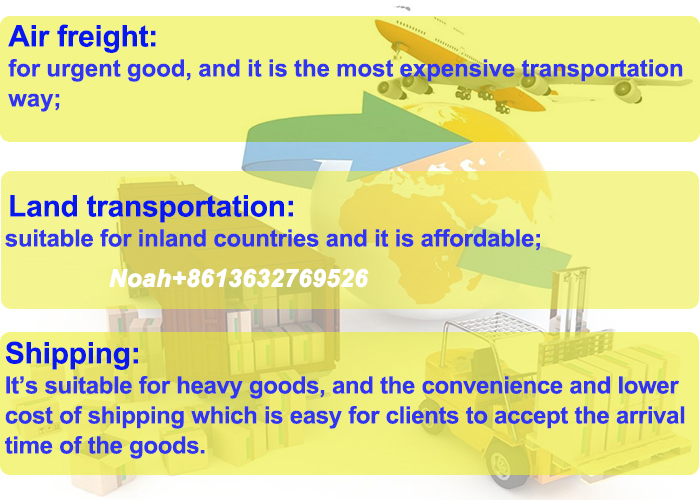

Delivery: by sea, air, land transport.

Market

Our products had exported to more than 20 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:

SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

Shipping and Delivery

We usually transport the goods to the port in containers and then ship them to the destination. For the transportation of machines, land transportation and air transportation are also possible.

FAQ

- Does your machines have quality certificates?

- We are high-tech enterprise with CE, SIRA, CCC , ISO awarded as “Well-know brand” and many technology patents, and have rich experience (more than 11 years) in LED light production line program.

- What is your actual speed of your products?

- For the actual speed of the machine which is constrained by many factors, that related to the number of the components, the time to send PCB board and receive the board that will have influence on the speed when in production, and is decide for the actual products and needs.

- Can you accept CIF as the quoted price?

- We only accept EXW as the quoted pricefor it is convenient and lower cost for both sides.

- Can I go and see if you have sold the equipment to India?

- Yes, we have sold our machine in India, but for the fact we can’t decide it for my customer, but I will try to contact my customer. Hope you can understand, because no one wants their competitors to visit their manufacturing site.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com