Description

Machine main features

- PCB transport and clamping system

- The PCB loading direction can be selected and combined freely;

- Unique crafted internal gear conveyor belt to prevent jamming;

- Programmable transport speed control makes PCB stop more precise;

- Adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh.

- Stencil positioning system

- Arch bridge-shaped suspension hanging direct-contact scraper;

- The size of steel mesh is universal, with goof and wide applicability;

- Segmented fixed steel mesh frame.

- Scraper system

- Programmable suspension self-adjusting stepper motor drives print head;

- Bilateral double-slider positioning type slide rail structure ensures the accuracy and smoothness of running before and after printing;

- Slide rail type scraper system, improve operation stability and prolong time;

- Embedded scale, never fall off.

- Operation system

- Easy to learn and easy to use friendly operation interface;

- With good human-machine dialogue function;

- Make program files with teaching and navigation functions, with prompts for each step;

- One key switch between Chinese and English, with operation log, fault record analysis and diagnosis.

- Image and optical system

- X,Y axis adopts high-precision grinding ball screw, driven by servo motors at both side;

- The polarizer is added inside, and the mark different shapes is automatically and accurately grasped, and the upper, lower and coaxial three way uniform light sources.

|

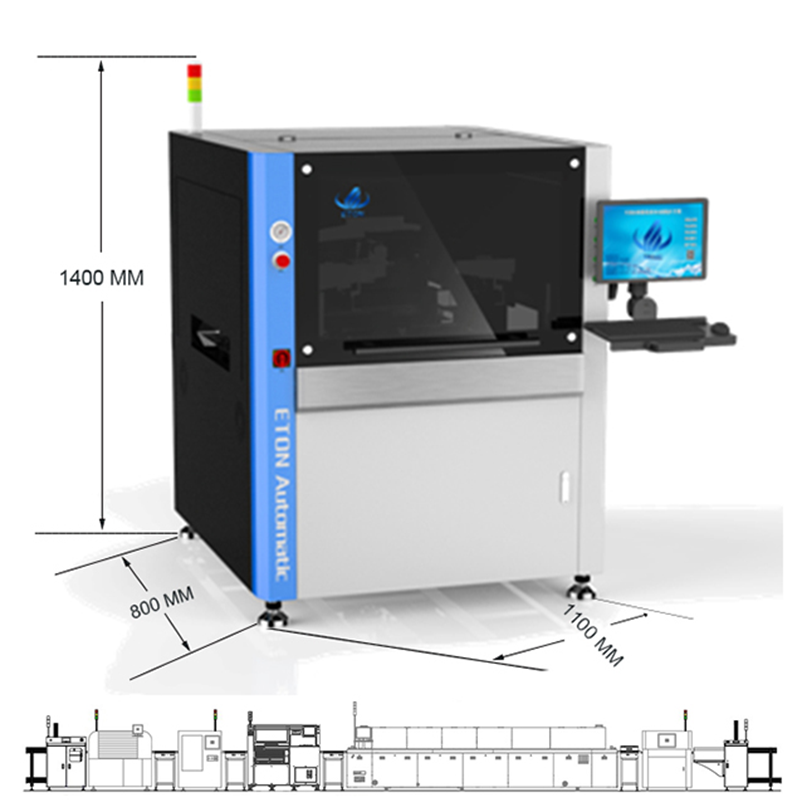

Model |

ET-5235 |

|

PCB size |

Max:520*350 mm Min:50*50 mm |

|

Transport height |

900±20mm |

|

Transport speed |

Max 1200mm/s programmable |

|

Printing accuracy |

±0.025mm |

|

Cycle time |

≤9s(Excluding printing&cleaning) |

|

Control method |

PC control |

|

PCB transfer overhead height |

10mm |

- Focusing on SMThigh speed pick and place machine more than 20 years

- The products exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc.

- ETON obtained 9 invention patents, 112 practical patents, 12 software copyrights of intellectual property technologies, to be a leading manufacturer of SMT trade.

Step 1: Wrap with stretch film to prevent the equipment from.

Step 2: Vacuum paper packaging and moisture-proof bag, so that the machine can be kept dry during transportation to prevent moisture.

Step 3: Use straps and triangular wood to fix the machine to prevent damage to the machine during transportation.

Step 4: Each exported machine will be equipped with sturdy export wooden boxes, to ensure that the delivered product is good.

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

- What is your merits of the machine to others production?

- Initially, we have a strong R&D department for studying our productions, and our clients can enjoy free up-grade of the machine to get latest information about technology and equipment, besides, we have a 52000 square meters industrial park to serve the production, assembly, and commissioning of our machines.

- If I need a perfect line of the machine can you supply?

- Yes, for the requirements of a whole line for production, we have professional equipment to make up for a perfect production line for your products, on account of we have a 50000 square meters of industrial park and excellent R&D staff, which can produce 50 sets of machine per month.

- Can you accept D/P or D/A as the payment term?

- For our regular payment terms, we usually use T/T.

- Whether you have professional engineers for installation of the machine in India?

- Yes, we have professional engineers in India to provide considerable service to our clients.