Description

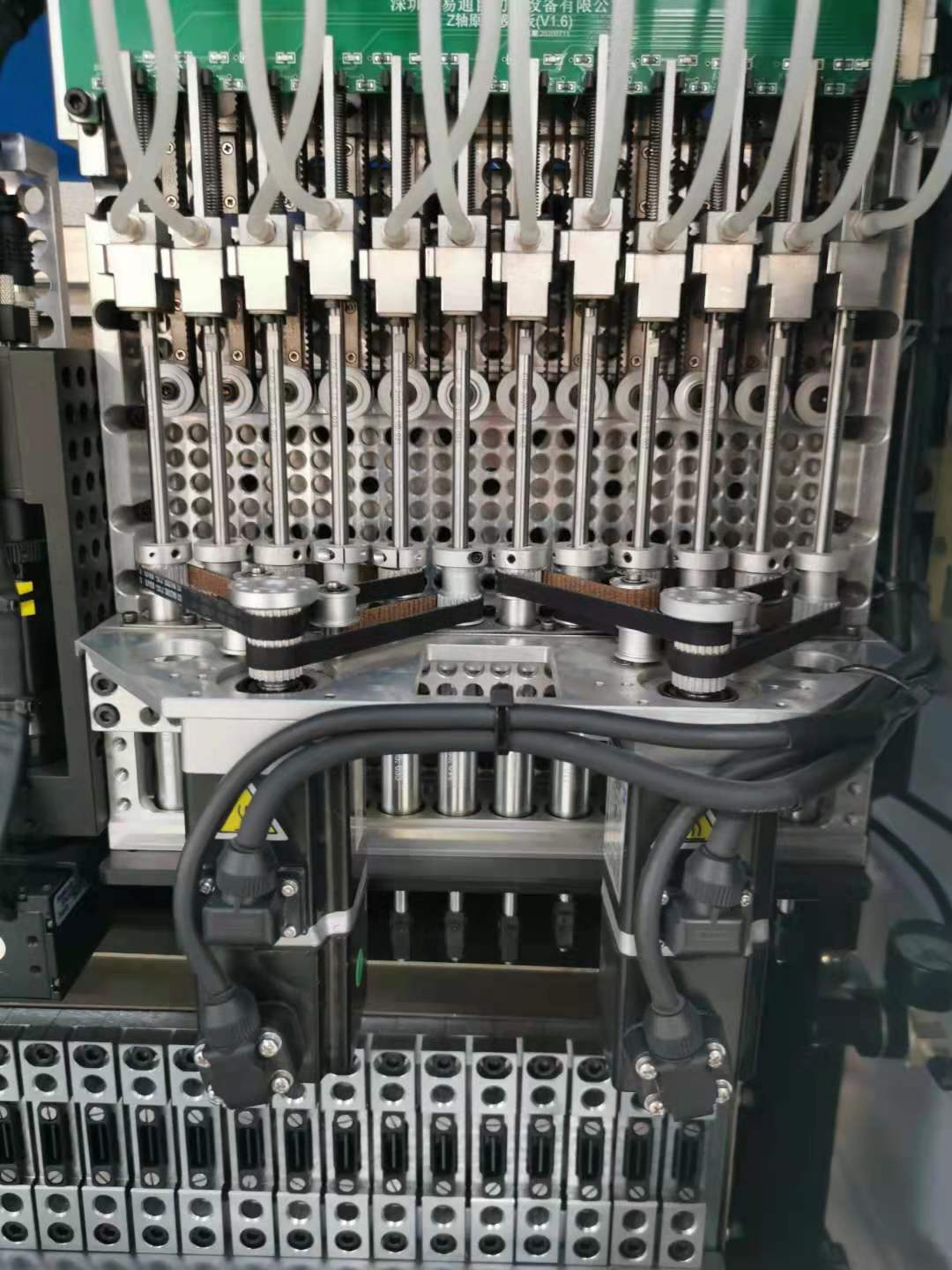

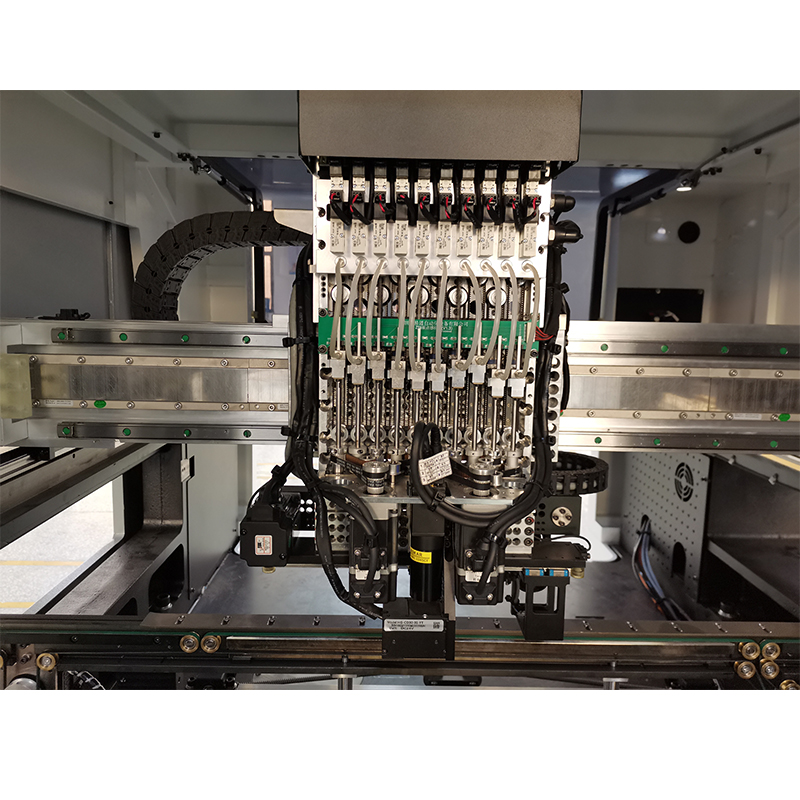

Machine main features

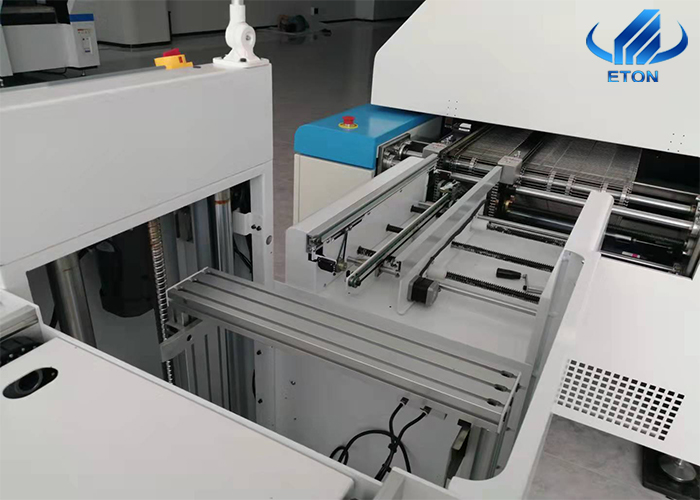

- The device of unloading PCB in the SMT production line;

- PLC control, color man-machine interface operation;

- Adopting the structure of steeping motor to push the board, the force and speed of the pushing board can be adjusted;

- Auxiliary positioning brake system, accurate positioning, fast rising and falling speed, high production efficiency;

- Multiple electric distribution circuit protection, safe and reliable;

- Acousto-optic alarm system, abnormal information text prompt, easy operation and maintenance.

- Standard SMEMA signal communication mode.

|

Description |

This equipment is used for the lowering operation of the circuit board in the production line |

|

Number of turnover frame |

One box on working, two boxes out of frame segment, two boxes into the frame segment(or customer specified) |

|

Send board time |

Around 6 s |

|

Frame change time |

Around 25 s |

|

PCB thickness |

0.4-0.3 mm |

|

Transmission height |

900±20 mm |

|

PCB size |

80*50-510*390 mm |

|

Dimension |

2250*1010*1200 mm |

|

Size of turnover frame |

535*460*570 mm |

|

Approximate weight |

About 240 KG |

|

Transmission direction |

Left-right, right-left |

|

Air pressure and air flow |

4-6 Bar, up to 1L/min |

Market

Our products had exported to more than 20 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:

SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

Our Exhibitions

Eton has participated in many exhibitions of foreign countries , such as India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, etc and trading with more than 20 countries. Furthermore, we have took part in our domestic large exhibition, like Guangzhou Guangya Exhibition, Shanghai Munich Exhibition, Chongqing LED light Exhibition, etc.

Packages

Keep a good quality of the machine when during transportation till the destination of our clients which is an imperative aspect for one of a suitable service for our clients to buy our machine, so making sure of a qualified and sturdy packing is a key mission for us, here are the specified steps for your reference:

Service

Maintenance period 1 year

One year warranty during warranty any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients

On-site service

We have some official site in India as Mumbai and New Delhi, also have site in Egypt, Turkey that can provide service timely with our engineers.

According to your needs, dedicated senior engineer will come to your factory for free install and training you how to operate the machine.

Shipping and Delivery

As to the part of shipping and delivery, there are three ways for your reference, and different way is for different situations:

Land transportation: suitable for inland countries and it is affordable;

Air freight: for urgent good, and it is the most expensive transportation way;

Shipping: It’s suitable for heavy goods, and the convenience and lower cost of shipping which is easy for clients to accept the arrival time of the goods.

FAQ

- What is your merits of the machine to others production?

- Initially, we have a strong R&D department for studying our productions, and our clients can enjoy free up-grade of the machine to get latest information about technology and equipment, besides, we have a 50000 square meters industrial park to serve the production, assembly, and commissioning of our machines.

- If I need a perfect line of the machine can you supply?

- Yes, for the requirements of a whole line for production, we have professional equipment to make up for a perfect production line for your products, on account of we have a 50000 square meters of industrial park and excellent R&D staff, which can produce 50 sets of machine per month.

- How was your services?

- We ensure our clients to enjoy an optimal experience of the service of communication and relevant needs of the machine for installation, maintenance and free up- grade.

- Can you accept D/P or D/A as the payment term?

- For our regular payment terms, we usually use T/T.